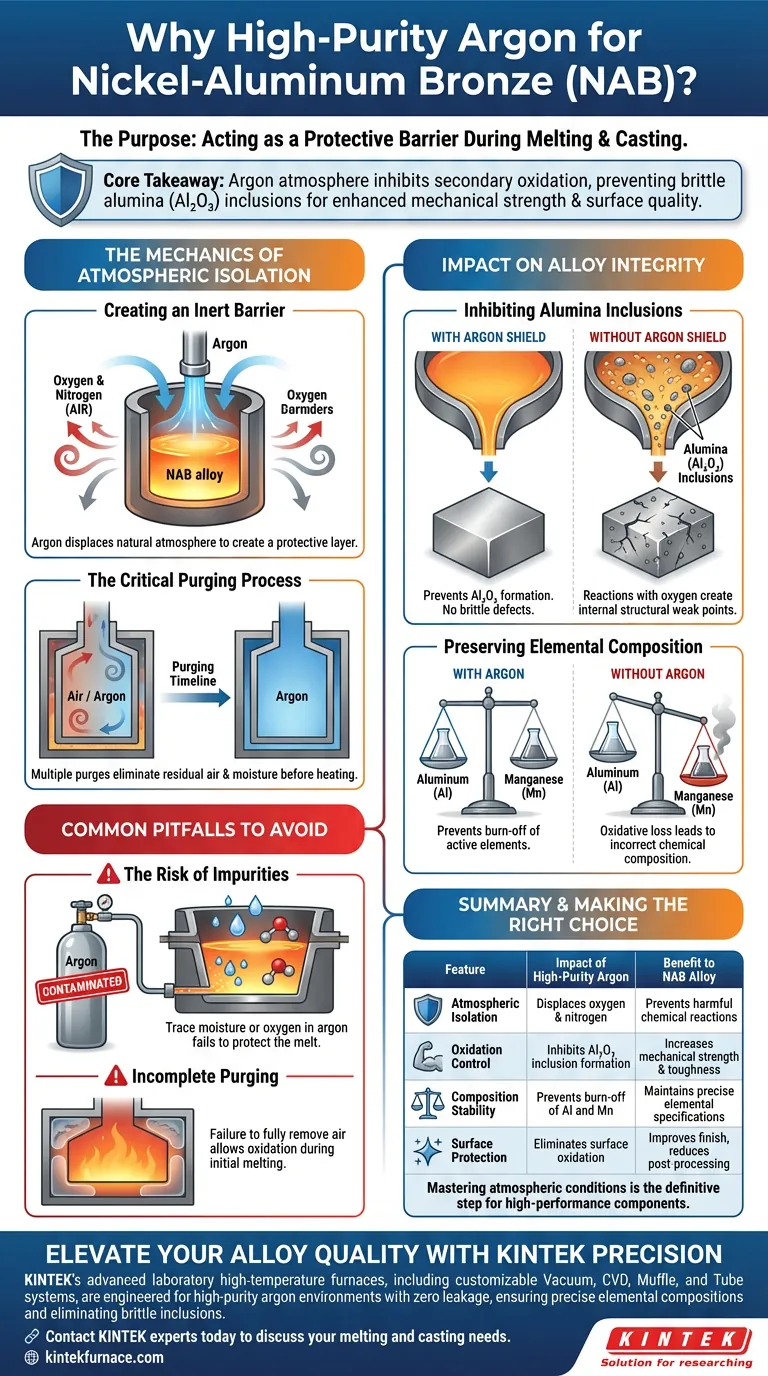

The primary purpose of using high-purity argon gas is to act as a protective barrier. It isolates the molten Nickel-Aluminum Bronze (NAB) from oxygen and nitrogen present in the surrounding air. By creating this inert atmosphere, the gas prevents chemical reactions that would otherwise degrade the material's quality during the critical melting and casting stages.

Core Takeaway The argon atmosphere is essential for inhibiting secondary oxidation, specifically preventing the formation of brittle alumina ($Al_2O_3$) inclusions. Eliminating these defects significantly enhances both the mechanical strength and the surface quality of the final alloy.

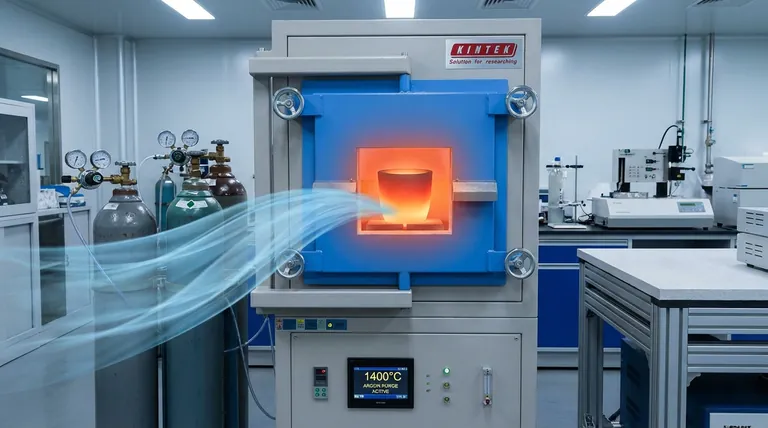

The Mechanics of Atmospheric Isolation

Creating an Inert Barrier

High-purity argon is introduced into the melting furnace to physically displace the natural atmosphere.

This creates a protective layer that effectively separates the molten alloy from reactive gases like oxygen and nitrogen.

The Critical Purging Process

To ensure total isolation, the furnace chamber is often purged multiple times before melting begins.

This step eliminates residual air and moisture, ensuring the environment is chemically inert before the metal reaches reactive temperatures.

Impact on Alloy Integrity

Inhibiting Alumina Inclusions

The most significant threat to NAB quality is the reaction between its aluminum content and atmospheric oxygen.

This reaction produces alumina ($Al_2O_3$) inclusions, which are brittle particles that compromise the metal's internal structure.

Argon shielding effectively stops this secondary oxidation, ensuring the alloy remains free of these structural defects.

Preserving Elemental Composition

High temperatures make active elements within the alloy, such as aluminum and manganese, highly susceptible to oxidative loss.

A low-oxygen argon atmosphere prevents these elements from burning off.

This ensures the final casting retains the precise chemical composition required for its intended performance.

Common Pitfalls to Avoid

The Risk of Impurities

The effectiveness of this process relies entirely on the purity of the argon gas.

Using gas that contains trace amounts of moisture or oxygen will fail to protect the melt.

Incomplete Purging

Simply introducing argon is not enough; the chamber must be thoroughly purged of existing air.

Failure to remove residual atmosphere before heating will allow oxidation to occur during the initial melting phase, regardless of the argon added later.

Making the Right Choice for Your Goal

To maximize the quality of your Nickel-Aluminum Bronze castings, apply the following principles:

- If your primary focus is Mechanical Strength: Prioritize high-purity argon to prevent brittle alumina inclusions that create internal weak points.

- If your primary focus is Surface Finish: Use a consistent argon shield to inhibit surface oxidation, resulting in a cleaner cast that requires less finishing.

Mastering the atmospheric conditions is the definitive step in transforming raw NAB materials into high-performance components.

Summary Table:

| Feature | Impact of High-Purity Argon | Benefit to NAB Alloy |

|---|---|---|

| Atmospheric Isolation | Displaces oxygen and nitrogen | Prevents harmful chemical reactions |

| Oxidation Control | Inhibits Al2O3 inclusion formation | Increases mechanical strength and toughness |

| Composition Stability | Prevents burn-off of Al and Mn | Maintains precise elemental specifications |

| Surface Protection | Eliminates surface oxidation | Improves finish and reduces post-processing |

Elevate Your Alloy Quality with KINTEK Precision

Don't let oxidation compromise your Nickel-Aluminum Bronze components. KINTEK’s advanced laboratory high-temperature furnaces are designed to provide the rigorous atmospheric control your research and production demand.

Backed by expert R&D and manufacturing, we offer customizable Vacuum, CVD, Muffle, and Tube systems engineered to handle high-purity argon environments with zero leakage. Whether you need to eliminate brittle inclusions or preserve precise elemental compositions, our technical team is ready to build the perfect solution for your lab.

Contact KINTEK experts today to discuss your melting and casting needs.

Visual Guide

References

- Yinxun Tan, Zhao Yizhi. Effect of Al/Ni Ratio on the Microstructure and Properties of Nickel–Aluminum Bronze Alloys. DOI: 10.3390/ma17061330

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a single-roller melt-spinning system facilitate Fe-based amorphous alloys? Achieve Precision Rapid Quenching

- Why is a vacuum drying oven required for precursor mixtures? Achieve Stable, High-Quality Powder Processing

- How do regenerative burners enhance the energy efficiency of billet heating furnaces? Boost Performance by 50%

- Why is 800 °C Required for Ln-MoP@C Phosphorization? Unlock Superior Catalyst Engineering

- What are the advantages of using a batch furnace? Achieve Unmatched Process Flexibility and Precision

- What is the function of the slow cooling feature in a furnace for Li2.7Sc0.1Sb? Master Single-Crystal Quality

- What is the importance of defining accurate heat transfer coefficients for slag? Master Thermal Stress Prediction

- How is the problem of surface oxidation and decarburization addressed in conventional heat treatment? Learn the Machining Allowance Method