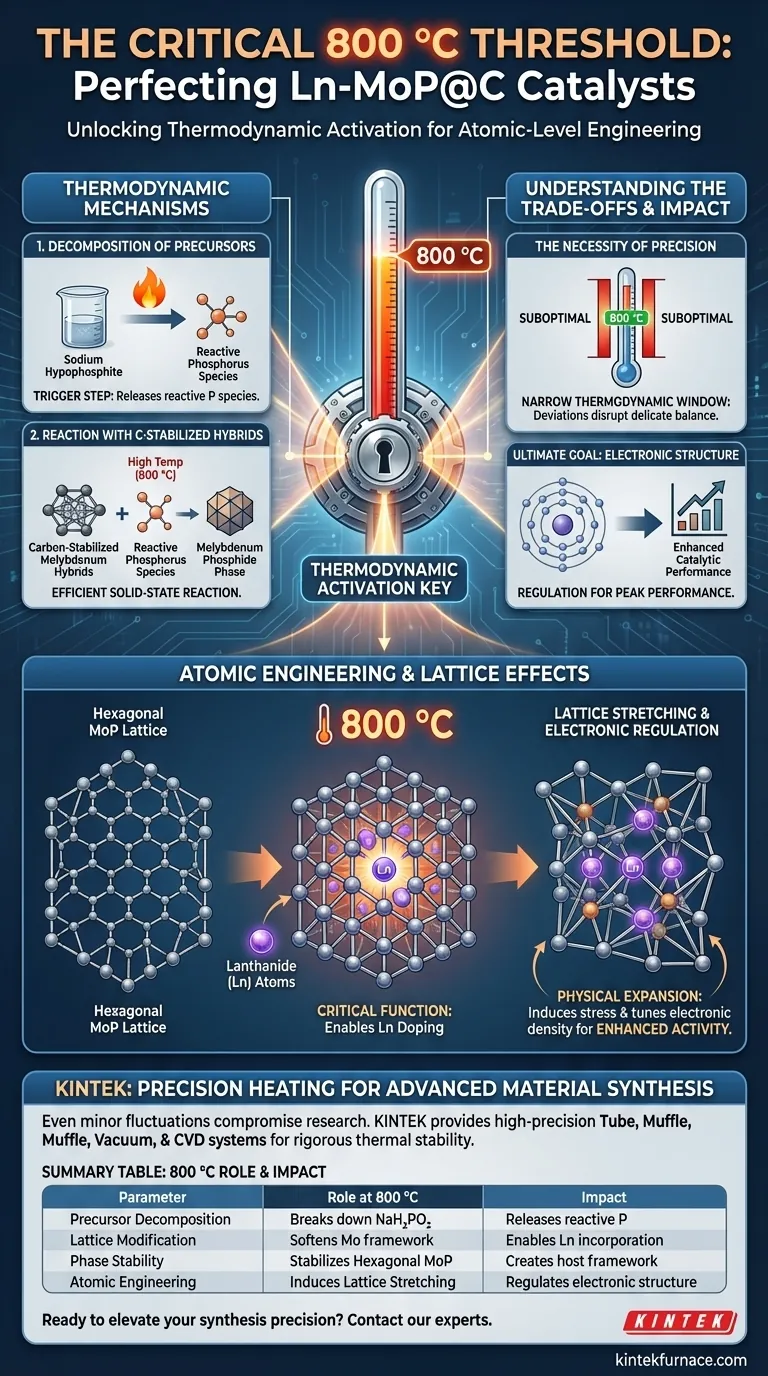

The specific temperature of 800 °C is critical because it creates the precise thermodynamic environment required to decompose the phosphorus source (sodium hypophosphite) and drive its reaction with carbon-stabilized molybdenum materials. This thermal energy is essential for forcing lanthanide atoms into the hexagonal molybdenum phosphide (MoP) lattice, a process that modifies the material's atomic structure to enhance catalytic activity.

The 800 °C threshold acts as a thermodynamic activation key, simultaneously unlocking the release of reactive phosphorus and softening the molybdenum lattice to accept lanthanide dopants. This precise thermal treatment engineers the electronic structure of the catalyst at the atomic level.

The Thermodynamic Mechanisms of Phosphorization

Decomposition of Precursors

At 800 °C, the tube furnace provides sufficient energy to fully decompose sodium hypophosphite. This decomposition is the trigger step, releasing the reactive phosphorus species needed for the subsequent chemical transformations. Without reaching this temperature, the phosphorus supply would be insufficient or kinetically limited.

Reaction with Carbon-Stabilized Hybrids

The phosphorus species generated do not act in isolation; they react with carbon-stabilized molybdenum hybrid materials. The high temperature ensures that this solid-state reaction proceeds efficiently, converting the precursors into the desired molybdenum phosphide phase.

Atomic Engineering and Lattice Effects

Lanthanide Incorporation

The most critical function of the 800 °C environment is enabling the successful doping of the material. It forces lanthanide (Ln) atoms to integrate into the crystal structure of the molybdenum phosphide. This is not a surface coating but an intrinsic modification of the material's makeup.

Formation of Hexagonal MoP

The specific phase formed under these conditions is the hexagonal MoP lattice. The thermal energy helps stabilize this specific crystal geometry, which serves as the host framework for the lanthanide dopants.

Lattice Stretching

When lanthanide atoms are incorporated into the hexagonal MoP lattice at this temperature, they induce physical stress on the crystal structure. This results in lattice stretching, a physical expansion or distortion of the atomic bonds. This structural deformation is a key feature of the synthesized catalyst.

Understanding the Trade-offs

The Necessity of Precision

The requirement for exactly 800 °C implies a narrow thermodynamic window for optimal synthesis. Deviating from this temperature disrupts the delicate balance required for simultaneous precursor decomposition and lattice doping.

Impact on Electronic Structure

The ultimate goal of the high-temperature treatment is electronic regulation. The lattice stretching caused by the 800 °C treatment alters the electronic density and band structure of the material. This tuning is what ultimately leads to enhanced performance; failing to achieve the correct temperature would result in a material with suboptimal electronic properties and lower catalytic efficiency.

Making the Right Choice for Your Goal

To ensure the successful synthesis of Ln-MoP@C catalysts, apply the following guidelines:

- If your primary focus is Structural Integrity: Maintain the furnace strictly at 800 °C to ensure the formation of the hexagonal MoP phase and the correct decomposition of sodium hypophosphite.

- If your primary focus is Catalytic Performance: Recognize that the 800 °C treatment is required to induce lattice stretching, which directly regulates the electronic structure for maximum activity.

By adhering to this specific thermal protocol, you ensure the precise atomic integration required for high-performance catalysis.

Summary Table:

| Parameter | Role at 800 °C | Impact on Catalyst |

|---|---|---|

| Precursor Decomposition | Breaks down sodium hypophosphite | Releases reactive phosphorus species |

| Lattice Modification | Softens molybdenum framework | Enables lanthanide (Ln) atom incorporation |

| Phase Stability | Stabilizes hexagonal MoP lattice | Creates the host framework for dopants |

| Atomic Engineering | Induces lattice stretching | Regulates electronic structure for activity |

Precision Heating for Advanced Material Synthesis

Achieving the exact 800 °C threshold is vital for the atomic engineering of Ln-MoP@C catalysts. At KINTEK, we understand that even minor temperature fluctuations can compromise your research outcomes. Backed by expert R&D and world-class manufacturing, we provide high-precision Tube, Muffle, Vacuum, and CVD systems designed to maintain the rigorous thermal stability required for complex phosphorization and lattice doping.

Whether you need a standard setup or a fully customizable high-temperature furnace tailored to your unique lab requirements, KINTEK offers the reliability you need to push the boundaries of catalytic science.

Ready to elevate your synthesis precision? Contact our technical experts today to find the perfect heating solution for your next breakthrough.

Visual Guide

References

- Jiancheng Li, Bin Liu. Balancing H <sup>*</sup> Adsorption/Desorption by Localized 4f Orbital Electrons of Lanthanide Dopants in Carbon‐Encapsulated MoP for Boosted Hydrogen Evolution. DOI: 10.1002/advs.202417583

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- Why is electromagnetic stirring technology employed during the melting process of Titanium-Copper (Ti–Cu) alloys?

- What are the process advantages of using a microwave hydrothermal high-pressure reactor? Master V-NbOPO4@rGO Synthesis

- How do laboratory thermostatic baths contribute to the phosphoric acid treatment of 3Y-TZP ceramics? Boost Bioactivity

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What key process environments does a Molecular Beam Epitaxy (MBE) system provide? Optimize CaF2 Thin Film Growth

- Why is a high-temperature furnace with gas flow control necessary for Li6MnO4 precursors? Achieve Precise Synthesis