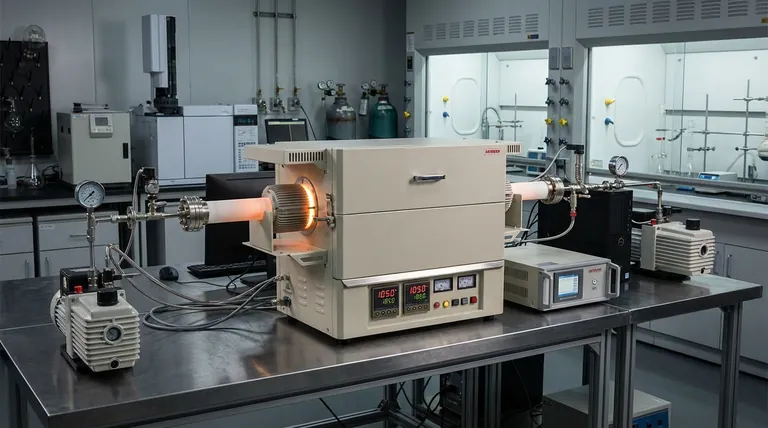

Precision is paramount when measuring the physical properties of volatile melts like antimony-tellurium. A high-temperature furnace equipped with an automatic temperature compensation system is required to maintain a strictly stable isothermal zone. Because the saturated vapor pressure of these melts exhibits an exponential relationship with temperature, even microscopic thermal fluctuations can lead to substantial, unacceptable errors in your experimental data.

The relationship between temperature and vapor pressure is not linear; it is exponential. Consequently, a stable heating environment is not merely a convenience—it is a mathematical necessity for distinguishing true material properties from experimental noise.

The Physics of Vapor Pressure Measurement

The Exponential Relationship

In thermodynamics, saturated vapor pressure does not increase gradually with heat; it surges. The relationship between the two is exponential. This means that as you increase the temperature of the antimony-tellurium melt, the vapor pressure rises disproportionately fast.

The Sensitivity of Data

Because of this exponential curve, a very small change in temperature ($dT$) results in a very large change in pressure ($dP$). If the furnace temperature drifts even slightly, the resulting pressure reading will vary wildly. To obtain a valid data point, the temperature must be locked firmly in place.

The Role of the Furnace System

Creating an Isothermal Zone

The primary function of the high-temperature furnace in this context is to create a uniform thermal environment. The sample must reside in an isothermal zone, where the temperature is consistent throughout the measuring space. This uniformity prevents temperature gradients that could skew the vapor pressure equilibrium.

Automatic Temperature Maintenance

Manual control is insufficient for the boiling point method. An automatic temperature compensation system actively monitors and corrects thermal conditions in real-time. This ensures that the environment remains stable without human intervention, guaranteeing the repeatability of your results across multiple test runs.

Understanding the Risks of Instability

The Pitfall of Thermal Drift

Without automatic compensation, furnaces are susceptible to thermal drift. If the temperature fluctuates during the measurement window, your data becomes unreliable. You will be unable to determine if a pressure change was caused by the melt's chemistry or a failure of the heating element.

Compromised Repeatability

Scientific rigor demands that an experiment can be repeated with the same results. Fluctuating temperatures introduce random variables that make repeatability impossible. High-precision control is the only way to minimize these variables and ensure data integrity.

Ensuring Experimental Success

To maximize the quality of your research on antimony-tellurium melts, consider your specific experimental goals.

- If your primary focus is Data Accuracy: You must utilize automatic compensation to neutralize the exponential sensitivity of vapor pressure to temperature changes.

- If your primary focus is Methodology: You must ensure your boiling point method setup creates a verified isothermal zone to guarantee the validity of your measurements.

By anchoring your thermal conditions, you transform volatile variables into reliable constants.

Summary Table:

| Factor | Impact on Sb-Te Melts | Requirement for Furnace |

|---|---|---|

| Vapor Pressure | Increases exponentially with temperature | High-stability heating control |

| Data Sensitivity | Small temp drifts cause large pressure errors | Real-time automatic compensation |

| Thermal Profile | Temp gradients skew equilibrium | Guaranteed isothermal zone |

| Consistency | Fluctuations prevent data repeatability | Active PID/Automatic monitoring |

Maximize Your Research Precision with KINTEK

Don't let thermal drift compromise your experimental integrity. KINTEK provides industry-leading high-temperature furnace systems, including Muffle, Tube, Rotary, and Vacuum CVD units, specifically engineered to maintain the strict isothermal zones required for volatile melt analysis. Backed by expert R&D and precision manufacturing, our equipment is fully customizable to meet your unique laboratory needs.

Ready to transform volatile variables into reliable constants? Contact KINTEK today for a customized solution.

References

- В. Н. Володин, Azamat Tulegenov. Thermodynamics of Liquid Alloys and Vapor–Liquid Equilibrium in the Antimony–Tellurium System. DOI: 10.1007/s12540-023-01564-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the benefits of cold compacting and sintering? Boost Efficiency and Cut Costs in Manufacturing

- What is the purpose of sintering in materials science? Transform Powders into Dense, High-Strength Components

- Why is a laboratory drying oven used for cottonseed oil extraction? Achieve Maximum Yield and Accuracy

- How does the post-rolling annealing process improve the interfacial microstructure? Enhancing Titanium-Steel Bond Strength

- What role does an industrial electric furnace play in PAI? Master Thermal Preparation for Metal Matrix Composites

- What is the function of a forced air drying oven in the dehydration of acid-washed zeolite? Ensure Sample Purity.

- Why is a vibratory mill used for ultra-fine grinding when preparing magnesite samples for zeta potential tests?

- What advantages does peat char offer compared to traditional charcoal? Boost Your Furnace Efficiency by 22%