At its core, cold compacting and sintering is a powder metallurgy process favored for its significant economic and production advantages. The primary benefits are lower costs, simpler equipment requirements, and faster processing times, making it exceptionally well-suited for the large-scale manufacturing of components where ultimate material density is not the primary concern.

The fundamental choice between cold compacting and an alternative like hot pressing is a strategic trade-off. Cold compacting and sintering prioritizes manufacturing efficiency—speed and cost—while potentially compromising on the final material's maximum density and mechanical strength.

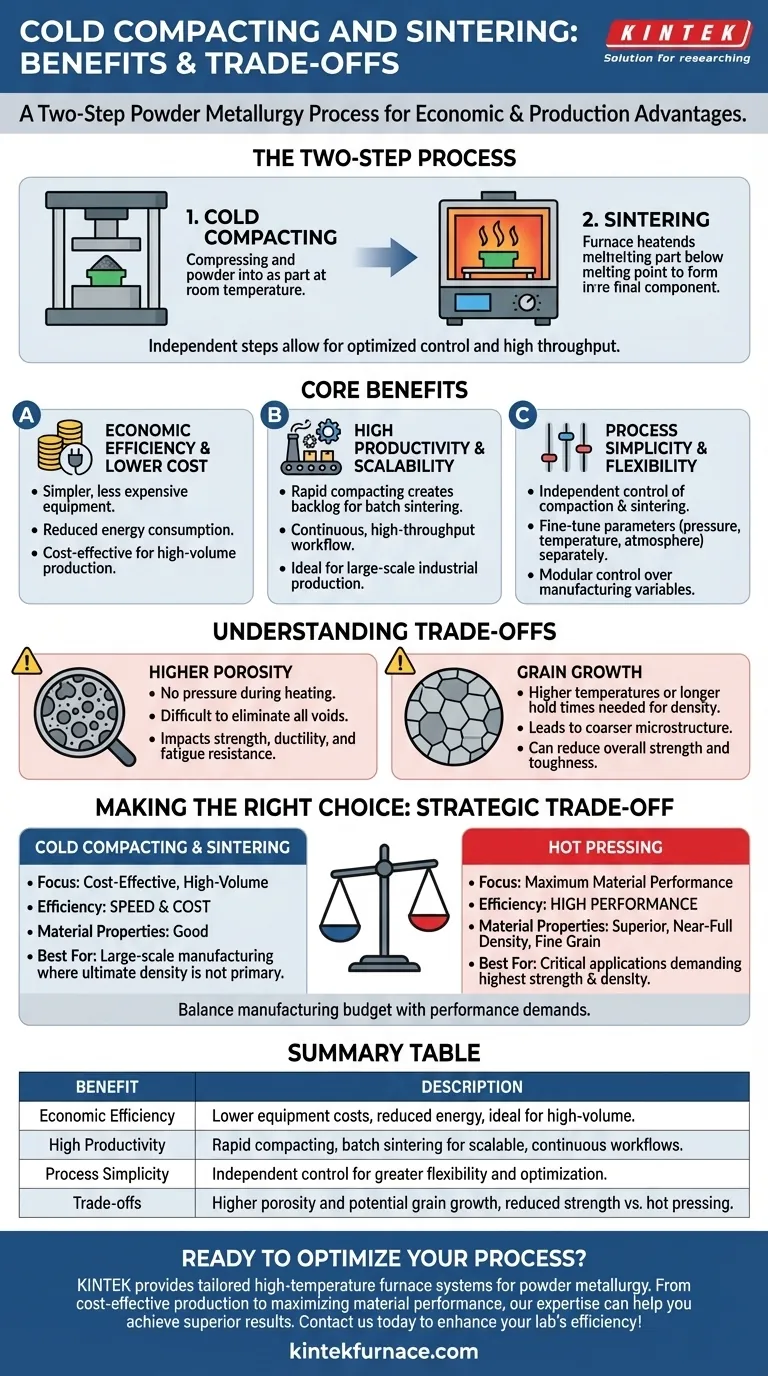

The Core Advantages of Cold Compacting and Sintering

This two-step method involves first pressing metal powder at room temperature to form a "green" compact, followed by heating (sintering) it below its melting point to bond the particles. The separation of these two steps is the source of its main benefits.

Economic Efficiency and Lower Cost

The machinery required for cold compaction is significantly less complex and expensive than the equipment needed for hot pressing, which must simultaneously apply extreme heat and pressure.

This lower equipment cost, combined with reduced energy consumption during the unheated pressing stage, makes the entire process more cost-effective, especially for high-volume production runs.

High Productivity and Scalability

The most significant operational advantage is the ability to optimize the compacting and sintering steps independently.

Compacting can be performed very rapidly, creating a backlog of green parts that can then be sintered in large batches. This decoupling allows for a continuous, high-throughput workflow that is ideal for large-scale industrial production, a sharp contrast to the slower, single-part cycle of hot pressing.

Process Simplicity and Flexibility

Separating the two stages simplifies process control. You can fine-tune compaction pressures and then separately optimize sintering temperatures and atmospheres to achieve the desired final properties. This modularity offers a greater degree of control and flexibility over the manufacturing variables.

Understanding the Trade-offs: Performance vs. Efficiency

While highly efficient, cold compacting and sintering involves inherent compromises that are critical to understand. The final material properties are often different from those achieved through methods that apply simultaneous heat and pressure.

The Challenge of Porosity

Parts made via cold compacting and sintering typically exhibit higher residual porosity compared to those made by hot pressing.

Without pressure being applied during the heating phase, it is more difficult to completely eliminate the voids between the initial powder particles. This remaining porosity can negatively impact mechanical properties such as strength, ductility, and fatigue resistance.

Grain Growth and Mechanical Properties

To achieve sufficient density, the separate sintering step often requires higher temperatures or longer hold times. These conditions can lead to grain growth, resulting in a coarser microstructure.

A coarser grain structure can reduce the material's overall strength and toughness, a key consideration for high-performance applications.

When to Consider an Alternative: Hot Pressing

Hot pressing is the preferred method when the primary goal is to achieve near-full density and a fine-grained microstructure. It excels at producing components with superior mechanical properties but at the cost of lower productivity and significantly higher operational expenses.

Making the Right Choice for Your Goal

The decision to use cold compacting and sintering must be aligned with your specific project requirements, balancing cost, volume, and performance.

- If your primary focus is cost-effective, high-volume production: Cold compacting and sintering is the superior choice, delivering good material properties with unmatched manufacturing efficiency.

- If your primary focus is maximum material performance: For critical applications demanding the highest possible density and mechanical strength, the higher cost and lower throughput of hot pressing are a necessary investment.

Ultimately, selecting the right process depends on a clear understanding of the balance between your manufacturing budget and the performance demands of the final component.

Summary Table:

| Benefit | Description |

|---|---|

| Economic Efficiency | Lower equipment costs and reduced energy consumption, ideal for high-volume production. |

| High Productivity | Rapid compacting and batch sintering enable scalable, continuous workflows. |

| Process Simplicity | Independent control of compaction and sintering for greater flexibility and optimization. |

| Trade-offs | Higher porosity and potential grain growth may reduce mechanical strength compared to hot pressing. |

Ready to optimize your manufacturing process with advanced furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace systems. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to meet your unique experimental needs with strong deep customization capabilities. Whether you're focused on cost-effective production or maximizing material performance, our expertise in powder metallurgy processes like cold compacting and sintering can help you achieve superior results. Contact us today to discuss how we can enhance your lab's efficiency and drive innovation!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency