At its core, sintering is the process of using heat to transform a loosely packed powder or porous body into a solid, dense mass. This is accomplished by heating the material to a high temperature, but below its melting point, which causes the individual particles to fuse together. The primary purpose is to dramatically reduce porosity, which in turn increases the material's density, hardness, and mechanical strength.

Sintering is the essential manufacturing step that bridges the gap between a fragile, porous "green body" and a strong, dense, and functional engineering component. It enables the creation of high-performance parts from materials, like advanced ceramics and certain metals, that are difficult or impossible to shape through traditional melting and casting.

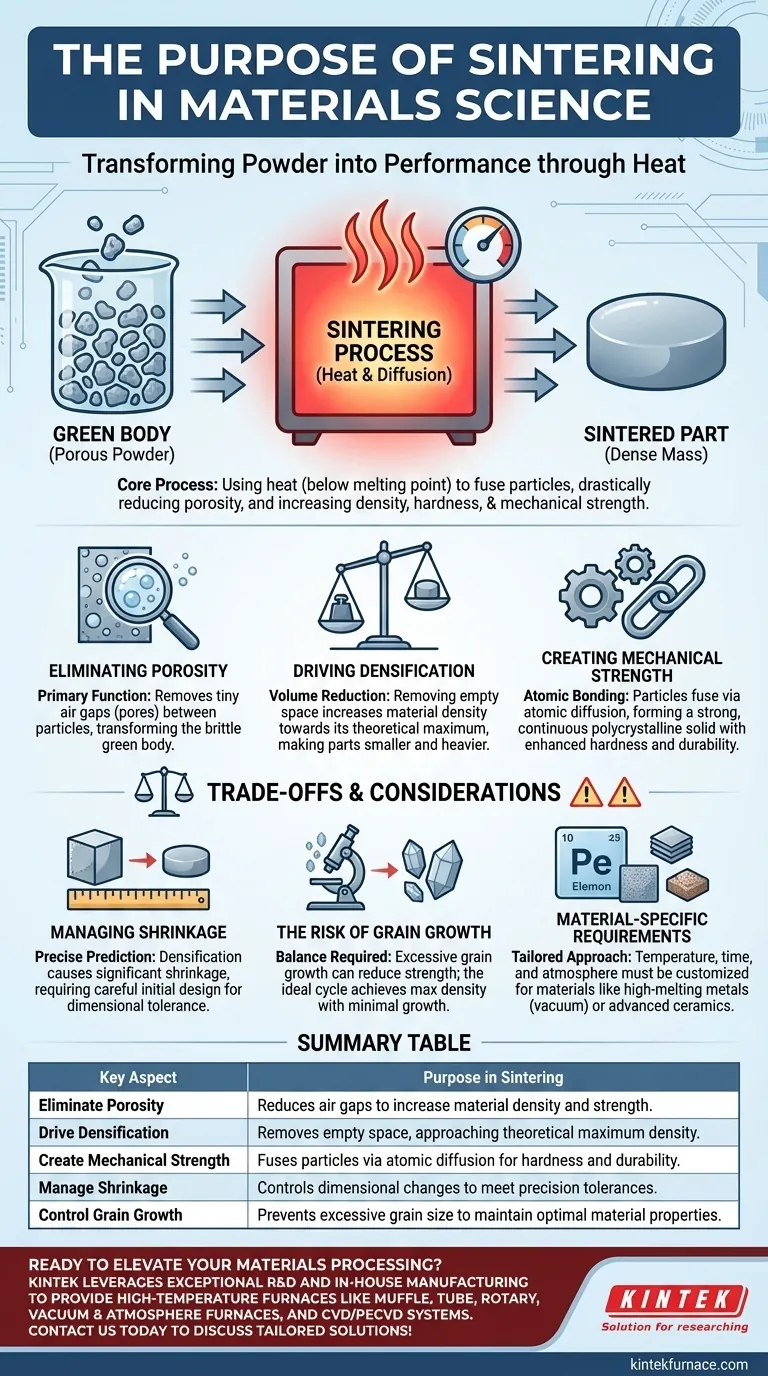

The Fundamental Goal: From Powder to Performance

Sintering is not merely a hardening process; it is a fundamental transformation of the material's internal structure. Its objectives are directly tied to achieving the final, desired properties of a component.

Eliminating Porosity

The starting material for sintering is often a compressed powder known as a "green compact" or "green body." This initial form is filled with tiny air gaps, or pores, between the particles, making it mechanically weak and brittle.

The primary function of sintering is to eliminate these pores. As the material is heated, the atoms gain enough energy to move, and the empty spaces are gradually filled in.

Driving Densification

By eliminating the pores, the sintering process drives densification. The total volume of the part decreases as the empty space is removed, causing the material's density to approach its theoretical maximum.

This increase in density is directly responsible for the dramatic improvement in the material's properties. The final part is significantly smaller, heavier for its size, and far more robust than the initial green body.

Creating Mechanical Strength

The final and most critical outcome is the creation of mechanical strength and hardness. During sintering, the boundaries between individual particles are eliminated as they fuse together through a process called atomic diffusion.

This creates strong atomic bonds throughout the material, forming a continuous, solid mass called a polycrystalline solid. It is this interconnected microstructure that gives a sintered ceramic its characteristic hardness or a sintered metal part its strength.

Understanding the Trade-offs and Considerations

While essential, the sintering process is a delicate balance of variables that must be carefully controlled to achieve the desired outcome. Mismanagement can lead to suboptimal or failed components.

Managing Shrinkage

Because densification involves the removal of empty space, the component will inevitably shrink. This shrinkage is significant and must be precisely predicted and accounted for in the initial design of the green body.

Failure to control shrinkage results in parts that do not meet final dimensional tolerances, a critical concern in precision manufacturing.

The Risk of Grain Growth

The same heat that drives densification can also cause grain growth, where smaller crystal grains within the material merge to form larger ones. While some grain growth is unavoidable, excessive growth can be detrimental.

In many materials, overly large grains can lead to reduced strength or increased brittleness. The ideal sintering cycle achieves maximum density with minimal grain growth.

Material-Specific Requirements

There is no one-size-fits-all approach to sintering. The optimal temperature, heating rate, time, and atmosphere depend entirely on the material.

For example, high-melting-point metals like tungsten and molybdenum are often sintered in a vacuum to prevent oxidation at the extreme temperatures required. Ceramics like zirconia require carefully controlled temperature profiles to achieve their renowned hardness without cracking.

How to Apply This to Your Project

Your approach to sintering should be guided by your end goal and the specific material you are working with.

- If your primary focus is creating high-performance ceramics: Sintering is the non-negotiable final step to achieve the density and hardness required for applications like dental implants, cutting tools, or thermal barriers.

- If your primary focus is working with high-melting-point metals: Sintering offers a practical and energy-efficient pathway to fabricate solid parts without needing to fully melt the material.

- If your primary focus is net-shape manufacturing: You must meticulously control the initial powder characteristics and the entire sintering cycle to manage shrinkage and produce parts that meet strict dimensional specifications.

By mastering the principles of sintering, you gain the ability to transform simple powders into precisely engineered components with predictable and powerful properties.

Summary Table:

| Key Aspect | Purpose in Sintering |

|---|---|

| Eliminate Porosity | Reduces air gaps to increase material density and strength |

| Drive Densification | Removes empty space, approaching theoretical maximum density |

| Create Mechanical Strength | Fuses particles via atomic diffusion for hardness and durability |

| Manage Shrinkage | Controls dimensional changes to meet precision tolerances |

| Control Grain Growth | Prevents excessive grain size to maintain optimal material properties |

Ready to elevate your materials processing with advanced sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're developing high-performance ceramics, working with high-melting-point metals, or focusing on net-shape manufacturing. Contact us today to discuss how our tailored furnace solutions can enhance your project's efficiency and outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency