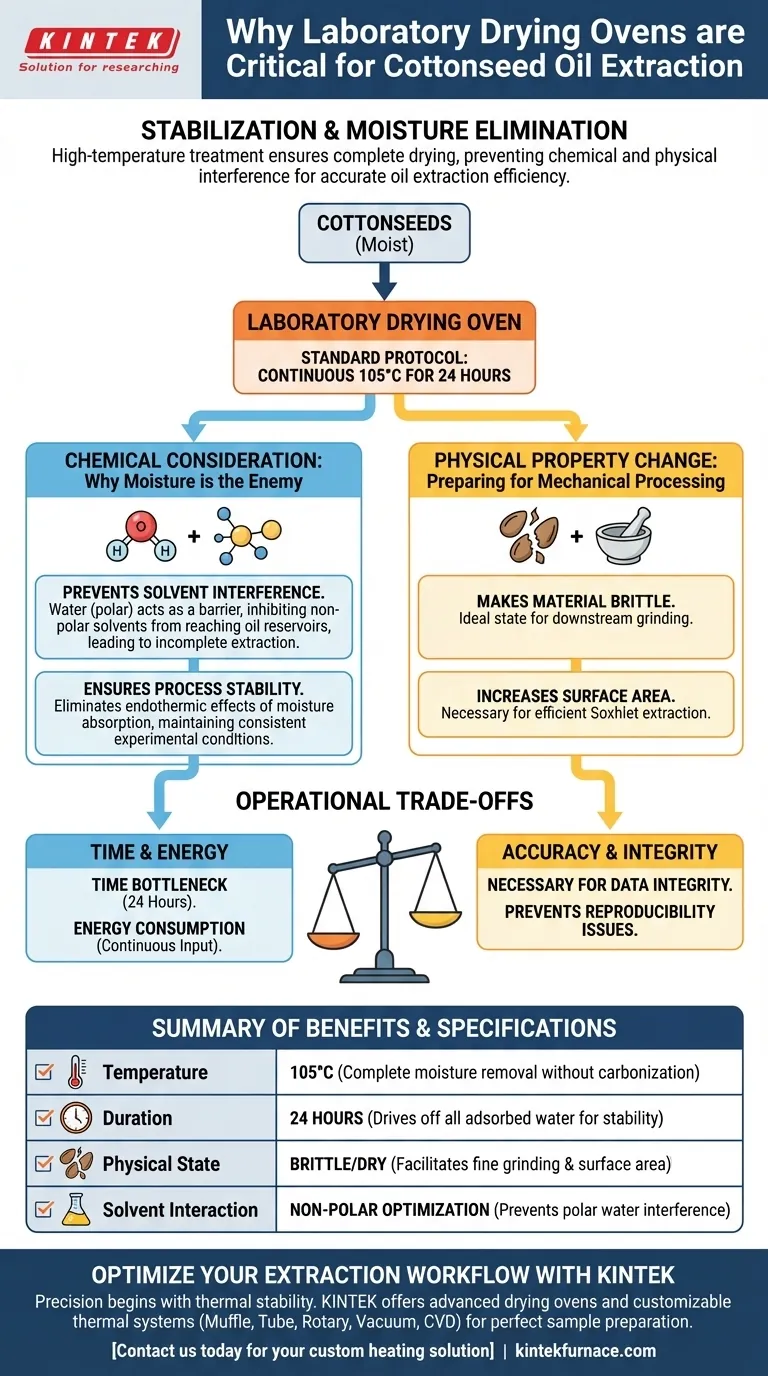

A laboratory drying oven serves as a critical stabilization tool used to eliminate moisture from cottonseeds prior to oil extraction. By subjecting the material to a continuous temperature of 105°C for 24 hours, this process ensures the sample is completely dry, preventing water from chemically or physically interfering with the subsequent solvent extraction efficiency.

Core Takeaway: Moisture is a contaminant that inhibits the interaction between non-polar solvents and oil reservoirs within the seed. High-temperature pretreatment creates a chemically neutral, dry state that is essential for effective grinding and accurate Soxhlet extraction.

The Mechanics of Pretreatment

The Standard Protocol

To achieve a baseline dry state, cottonseeds are heated continuously at 105°C for 24 hours.

This specific time-temperature combination is designed to drive off all physically adsorbed moisture without carbonizing the sample.

Preparing for Mechanical Processing

Beyond chemical considerations, drying changes the physical properties of the seed.

The removal of water renders the material brittle, creating an ideal state for downstream grinding. This mechanical breakdown is necessary to increase the surface area before the material enters the Soxhlet extractor.

Why Moisture is the Enemy of Extraction

Preventing Solvent Interference

Water is a polar substance, while the solvents used for oil extraction are typically non-polar.

If moisture remains in the cottonseeds, it creates a barrier that interferes with the solvent’s ability to penetrate the seed matrix. This results in incomplete extraction and inaccurate yield data.

Ensuring Process Stability

While specific to combustion in other contexts, the presence of moisture generally introduces endothermic effects—the absorption of heat.

In extraction and analysis, removing this variable ensures that the experimental conditions remain stable and that the data reflects the oil content, not the water content.

Operational Trade-offs

The Time Bottleneck

The most significant trade-off in this protocol is the time investment.

Dedicating 24 hours solely to drying creates a bottleneck in the workflow, limiting the number of samples that can be processed rapidly. However, rushing this step compromises the integrity of the entire extraction.

Energy Consumption vs. Accuracy

maintaining an oven at 105°C for a full day requires continuous energy input.

While this increases the operational cost per sample, it is a necessary expense to prevent the reproducibility issues that arise when moisture levels fluctuate between different batches.

Making the Right Choice for Your Goal

To maximize the quality of your data, align your process with the following principles:

- If your primary focus is Extraction Efficiency: Adhere strictly to the 24-hour drying period to ensure no water competes with your solvent for access to the oil.

- If your primary focus is Sample Preparation: Use the drying phase to facilitate easier, finer grinding, which will further enhance your final yield.

Data integrity begins with a dry, stable sample.

Summary Table:

| Feature | Protocol Specification | Benefit to Extraction |

|---|---|---|

| Temperature | 105°C | Ensures complete moisture removal without carbonization |

| Duration | 24 Hours | Drives off all adsorbed water for chemical stability |

| Physical State | Brittle/Dry | Facilitates fine grinding and increased surface area |

| Solvent Interaction | Non-polar Optimization | Prevents polar water interference with extraction solvents |

Optimize Your Extraction Workflow with KINTEK

Precision in oil extraction begins with uncompromising thermal stability. As a leader in laboratory high-temperature solutions, KINTEK provides the advanced drying ovens and thermal systems necessary to ensure your samples are perfectly prepared for Soxhlet extraction and analysis.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to meet the rigorous demands of your lab. Don't let moisture compromise your data integrity—partner with KINTEK for equipment that delivers reproducibility and efficiency.

Contact us today to find your custom heating solution

Visual Guide

References

- Gyeongnam Park, Eilhann E. Kwon. Use of defatted cottonseed-derived biochar for biodiesel production: a closed-loop approach. DOI: 10.1007/s42773-024-00394-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does an industrial-grade POCl3 diffusion furnace system play in DOSS? Master Quantitative Phosphorus Control

- What is the primary process function of a constant temperature drying oven? Ensure Catalyst Structural Integrity

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- Why is achieving process pressure within defined time important? Boost Efficiency, Quality, and Safety

- What roles does a laboratory oven play in biochar production? Enhance Efficiency and Accuracy in Thermal Processing

- How does a vacuum environment influence the accuracy of thermoelectric performance measurements for TaAs2? Ensure Precision in Your Research

- Which type of furnace is better for specific applications? Choose the Right Furnace for Your Production Needs