Achieving process pressure within a defined time is critical because it directly dictates process efficiency, product quality, and operational cost. The time spent reaching a pressure setpoint is not merely a waiting period; it is a crucial phase of the process where delays translate directly into lost production, wasted energy, and potential quality control failures.

The speed at which a system reaches its target pressure is a key performance indicator of its overall health and economic viability. Failing to manage this ramp-up time effectively can jeopardize product consistency, inflate operational costs, and even introduce safety risks.

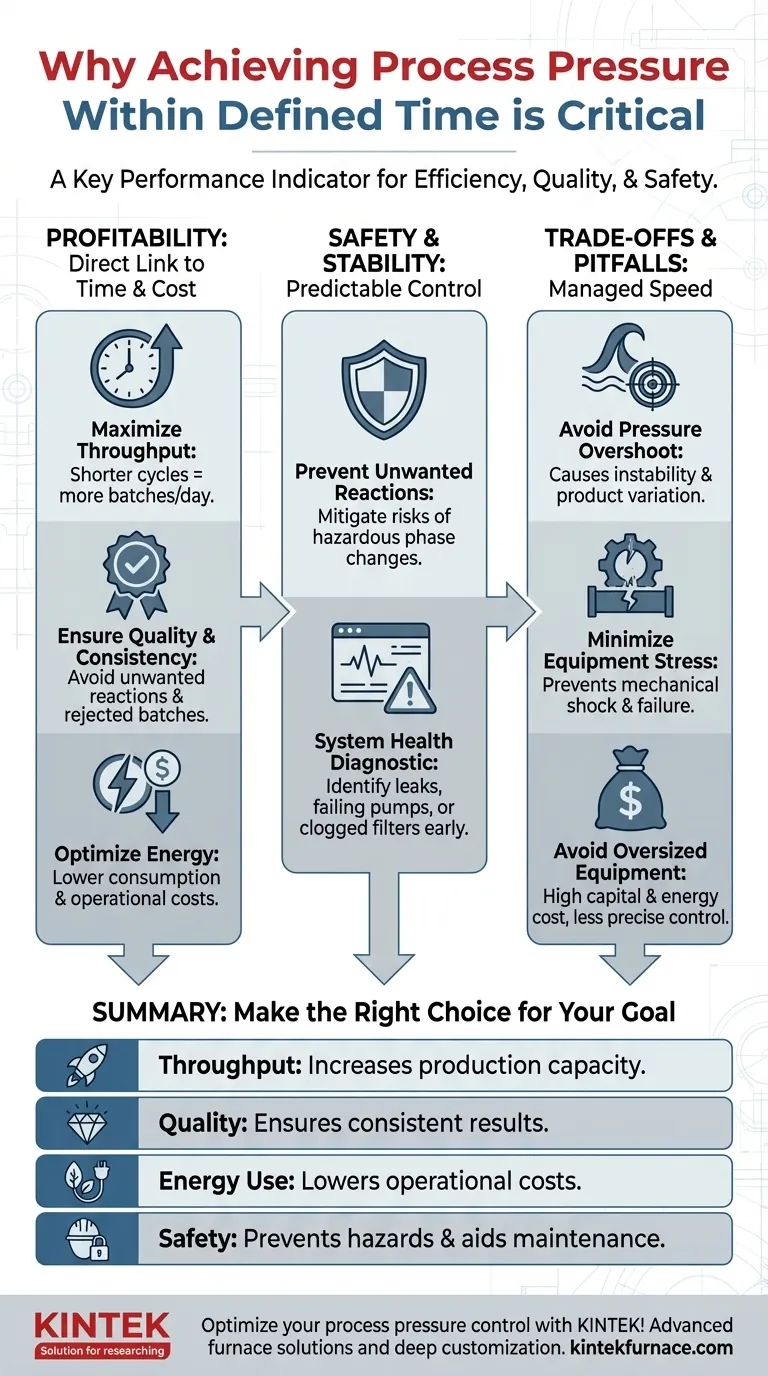

The Direct Link Between Time, Pressure, and Profitability

Understanding why the "time-to-pressure" matters requires looking beyond the pressure gauge and seeing its impact on the entire production cycle. Delays have cascading financial consequences.

Maximizing Throughput and Cycle Time

For any batch-based process, the total cycle time determines how many batches you can run per day. The pressure ramp-up is a non-productive part of that cycle.

By minimizing this ramp-up time, you shorten the overall cycle. This directly increases the plant's throughput and production capacity without needing to add more lines or equipment.

Ensuring Product Quality and Consistency

Many processes, from chemical reactions to sterilization, are defined by a specific "recipe" of pressure, temperature, and time. The ramp-up phase is part of this recipe.

If it takes too long to reach the target pressure, the material may be held at intermediate conditions for an extended period. This can lead to unwanted side reactions, incomplete sterilization, or inconsistent product morphology, resulting in rejected batches and wasted materials.

Optimizing Energy Consumption

Pumps, compressors, and vacuum systems consume significant energy. A system that takes an excessively long time to reach pressure is often operating inefficiently.

This could be due to leaks, failing components, or simply being undersized for the task. A properly designed system that reaches pressure quickly consumes less energy per batch, lowering the overall cost of production.

The Critical Role in Process Safety and Stability

Predictable pressure control is a cornerstone of a safe and stable industrial process. An inability to build pressure in a timely manner is often a symptom of a deeper issue.

Preventing Unwanted Phase Changes or Reactions

In certain chemical or cryogenic processes, lingering at the wrong pressure can cause materials to change phase unexpectedly or trigger hazardous side reactions. A swift and controlled transition to the desired operating pressure mitigates these risks.

Serving as a System Health Diagnostic

A sudden increase in the time it takes to reach pressure is a clear indicator that something has changed. It is often the first sign of a system leak, a failing pump, a clogged filter, or a faulty valve.

Monitoring this parameter allows maintenance teams to identify and rectify problems proactively before they lead to a full-blown shutdown or a safety incident.

Understanding the Trade-offs and Common Pitfalls

While a fast pressure ramp-up is generally desirable, pursuing speed at all costs can introduce new problems. The goal is controlled speed, not uncontrolled force.

The Risk of Pressure Overshoot

An overly aggressive ramp-up can cause the system pressure to "overshoot" the setpoint. The control system must then work to correct the error, which can cause oscillations and instability. This is often just as detrimental to product quality as a slow ramp.

Equipment Stress and Mechanical Shock

Rapidly pressurizing a system can induce significant mechanical stress on vessels, piping, and gaskets. In liquid systems, this can manifest as "water hammer," a damaging pressure surge that can lead to catastrophic equipment failure.

The Cost of Oversized Equipment

Specifying a pump or compressor that is far too large for the application will achieve a fast ramp-up, but it comes at a high price. Oversized equipment has a higher capital cost, consumes more energy, and can be difficult to control precisely at lower flow rates, leading to operational inefficiency.

Making the Right Choice for Your Goal

The ideal pressure ramp-up time is not universal; it is dictated by the specific needs of your process. You must align your system's performance with your primary objective.

- If your primary focus is maximizing production throughput: Prioritize a system sized to minimize the non-productive ramp-up time, directly shortening your overall batch cycle.

- If your primary focus is ensuring product consistency: Focus on the repeatability and control of the pressure ramp profile, as deviations in this time-pressure curve can lead to product variations.

- If your primary focus is safety and operational stability: Use the time-to-pressure metric as a key diagnostic tool to monitor system health and prevent failures before they occur.

Ultimately, treating pressure ramp-up time as a key performance indicator transforms it from a simple waiting period into a powerful lever for process optimization.

Summary Table:

| Key Aspect | Impact of Achieving Pressure Quickly |

|---|---|

| Throughput | Increases production capacity by shortening cycle times |

| Quality | Ensures consistent results and reduces batch rejections |

| Energy Use | Lowers operational costs through optimized consumption |

| Safety | Prevents hazards and aids in proactive maintenance |

Optimize your process pressure control with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency, quality, and safety. Contact us today to discuss how we can tailor solutions for your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary function of a vacuum oven for Mo-based catalyst precursors? Ensure Purity & Pore Integrity

- Why must High Vanadium High Speed Steel undergo multiple tempering cycles? Key to Unlocking Secondary Hardness

- What role does a high-pressure reactor play in the production of hydrochar? Optimize Biomass Carbonization

- Why is immediate quenching required after CTS treatment of mesoporous carbon? Preserve Your Material’s Atomic Structure

- Why is cordierite selected as the honeycomb support for HAN decomposition catalysts? Essential Design Insights

- Why is a laboratory blast drying oven necessary for Ni-TiN catalysts? Ensure Precision in Precursor Treatment

- What are some common types of batch furnaces? Find Your Perfect Heat Treatment Solution

- Why maintain argon and oxygen control in Titanium LMD? Ensure Peak Purity for Your High-Performance Components