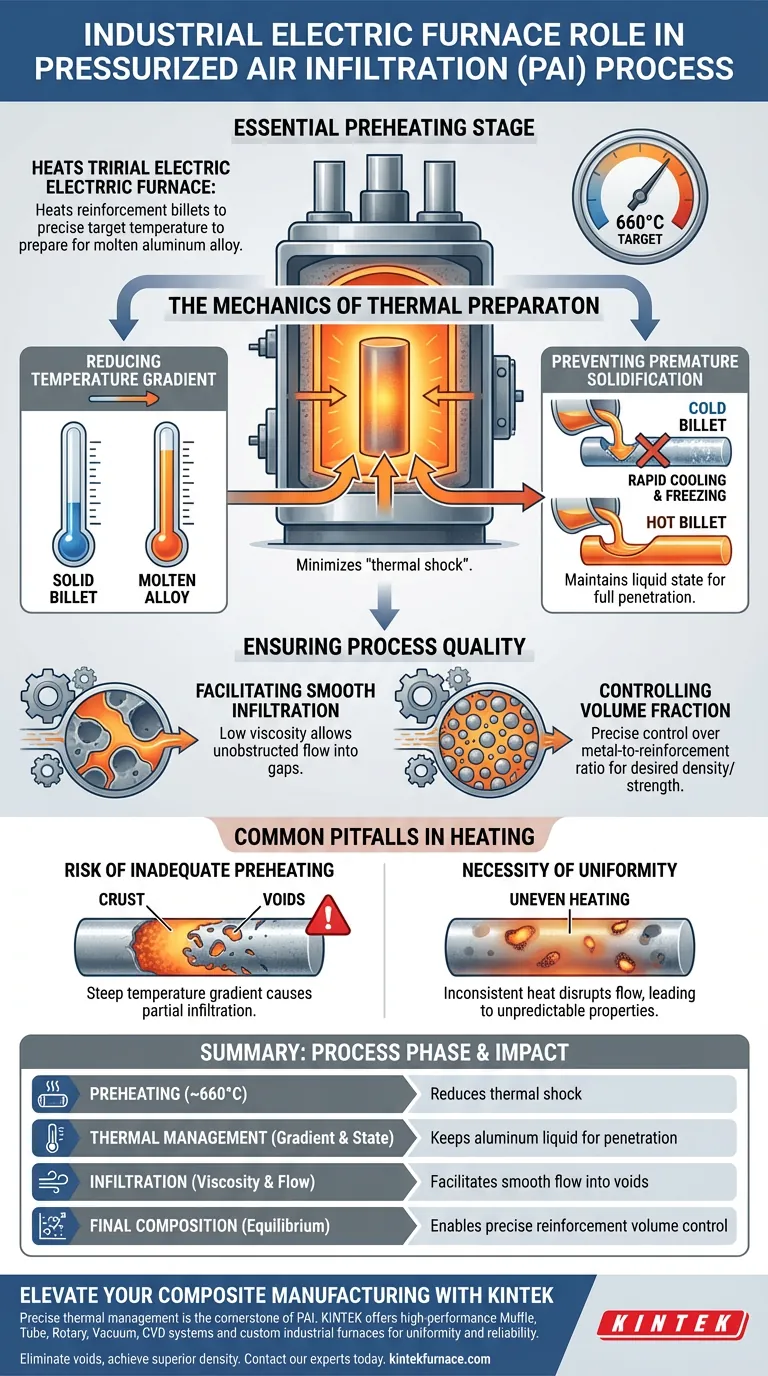

The industrial electric furnace functions as the essential preheating stage in the pressurized air infiltration (PAI) process. It heats billets containing reinforcement particles to a precise target temperature, typically around 660°C, to prepare them for the introduction of molten aluminum alloy.

By significantly reducing the temperature gradient between the solid billet and the molten metal, the furnace ensures the alloy remains liquid long enough to permeate the reinforcement material. This prevents blockage caused by cooling and guarantees a uniform composite structure.

The Mechanics of Thermal Preparation

Reducing the Temperature Gradient

The primary challenge in PAI is the thermal disparity between the liquid aluminum alloy and the solid reinforcement billet.

The electric furnace raises the billet's temperature to match or near the alloy's molten state, often 660°C. This minimizes the "thermal shock" the liquid metal experiences when it contacts the billet.

Preventing Premature Solidification

If molten aluminum touches a cold billet, it loses heat energy rapidly.

This rapid cooling causes the metal to freeze (solidify) before it can fully penetrate the mold. The furnace ensures the billet holds enough thermal energy to keep the aluminum in a liquid state throughout the infiltration phase.

Ensuring Process Quality

Facilitating Smooth Infiltration

For a high-quality composite, the metal must flow freely into the microscopic voids between reinforcement particles.

Preheating ensures the viscosity of the metal remains low, allowing it to smoothly infiltrate the gaps without obstruction. This creates a seamless bond between the matrix (metal) and the reinforcement.

Controlling Volume Fraction

The ultimate goal of the PAI process is to achieve a specific ratio of metal to reinforcement.

By maintaining the necessary temperature, the furnace allows for precise control over the volume fraction of the reinforcement phase. This ensures the final material meets its engineered density and strength specifications.

Common Pitfalls in Heating (The Trade-offs)

The Risk of Inadequate Preheating

If the furnace fails to reach the target temperature (e.g., 660°C), the temperature gradient remains too steep.

This leads to partial infiltration, where the metal creates a "crust" on the surface but leaves the interior of the billet void of metal. This results in a structurally compromised component.

The Necessity of Uniformity

The furnace must provide consistent heat throughout the billet, not just on the surface.

Uneven heating can cause localized solidification spots, disrupting the flow of the molten alloy and leading to unpredictable variations in the material's final properties.

Making the Right Choice for Your Goal

To maximize the effectiveness of the PAI process, focus on the relationship between temperature and flow.

- If your primary focus is Structural Integrity: Ensure your furnace is calibrated to reach the exact target temperature (e.g., 660°C) to prevent voids caused by premature metal freezing.

- If your primary focus is Material Consistency: Prioritize the duration of the preheating phase to ensure the core of the billet reaches thermal equilibrium with the molten alloy, guaranteeing precise volume fraction control.

Precise thermal management is the difference between a surface coating and a true composite material.

Summary Table:

| Process Phase | Furnace Function | Impact on Quality |

|---|---|---|

| Preheating | Reaches ~660°C target temperature | Reduces thermal shock between billet and alloy |

| Thermal Management | Minimizes temperature gradient | Keeps aluminum in liquid state for full penetration |

| Infiltration | Ensures low metal viscosity | Facilitates smooth flow into microscopic voids |

| Final Composition | Thermal equilibrium maintenance | Enables precise control of reinforcement volume fraction |

Elevate Your Composite Manufacturing with KINTEK

Precise thermal management is the cornerstone of successful pressurized air infiltration. At KINTEK, we understand that even a minor temperature deviation can compromise the structural integrity of your materials.

Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized industrial high-temp furnaces. Whether you need to heat billets to a perfect 660°C or require a fully customizable solution for unique research needs, our equipment delivers the uniformity and reliability your lab demands.

Ready to eliminate voids and achieve superior material density? Contact our technical experts today to find the perfect furnace solution for your application.

Visual Guide

References

- Ahmed hewidy, Ibrahim Sabry. MECHANICAL AND TRIBOLOGICAL CHARACTERISTICS OF STIR-CASTING Al2O3-SiC-Gr/Al6063 HYBRID COMPOSITE. DOI: 10.21608/jest.2024.334761

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- How does rapid quenching after diffusion treatment affect the material properties of the silicon structure? Lock-in Vital Phases

- How does the sintering process enhance conventional ceramics with Alumina? Boost Strength and Insulation

- What design considerations are important for custom vacuum chambers? Optimize for Performance, Cost, and Application Needs

- What is a benchtop industrial oven? Maximize Space and Efficiency in Your Lab

- What is the role of electric furnaces in the direct reduction of iron? Powering the Future of Green Metallurgy

- How does a Rapid Thermal Processing (RTP) system function? Optimize Nanowire Device Performance Today

- How does the QIO algorithm improve temperature control precision in electric furnaces? Achieve Global Optimization