Sintering is the critical manufacturing step that transforms loose alumina powder into a dense, high-performance ceramic. By applying heat below the material's melting point, the process fuses the individual powder particles together, dramatically increasing the material's hardness and density while establishing its low thermal and electrical conductivity.

The core principle of sintering is not melting, but solid-state diffusion. Thermal energy drives atoms to move between particles, closing the gaps and pores between them to create a single, monolithic piece with vastly improved properties.

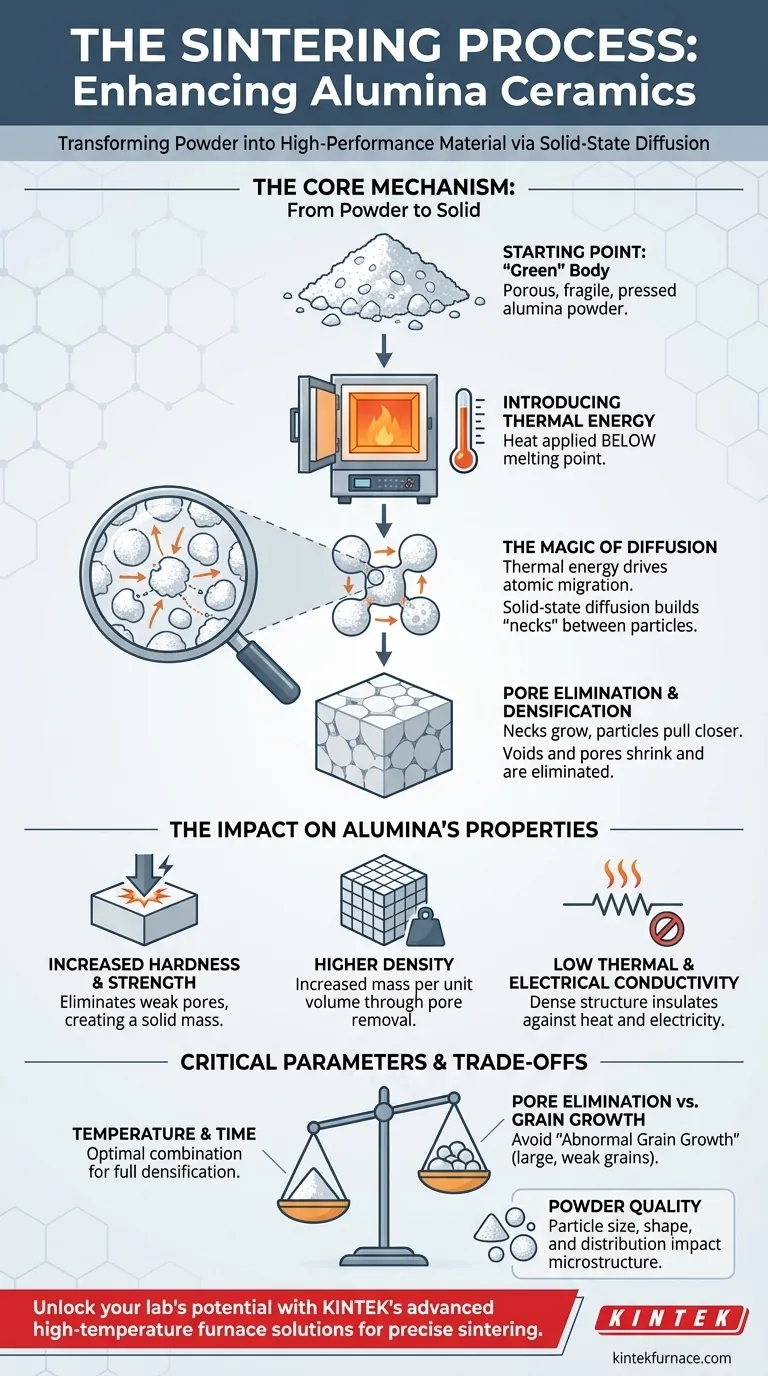

The Core Mechanism: From Powder to Solid

To understand how sintering enhances alumina, you must visualize the transformation on a microscopic level. It's a carefully controlled process of atomic migration.

The Starting Point: A 'Green' Body

The process begins by pressing fine alumina powder into a desired shape. This initial form, known as a "green body," is chalky, porous, and mechanically fragile. It has the shape of the final part but none of its required strength.

Introducing Thermal Energy

The green body is then placed in a high-temperature furnace. The temperature is raised significantly but kept below alumina's melting point. This heat doesn't liquefy the material; instead, it provides the kinetic energy for the atoms within the crystal lattice to become mobile.

The Magic of Diffusion

This atomic mobility is the key. Driven by a fundamental need to lower surface energy, atoms begin to migrate from the bulk of the powder grains to the points of contact between them. This process, called solid-state diffusion, builds "necks" or bridges between adjacent particles.

Pore Elimination and Densification

As these necks grow, they pull the centers of the grains closer together. The empty spaces, or pores, that were trapped between the powder particles begin to shrink and are eventually eliminated. This removal of void space is what causes the entire component to shrink and, most importantly, to densify.

The Impact on Alumina's Properties

This microstructural consolidation directly translates into the enhanced material properties required for demanding applications.

Drastically Increased Hardness and Strength

The pores in a green body are natural stress concentrators and points of failure. By eliminating these pores and fusing the grains into a solid mass, sintering removes these weak points. The result is a ceramic with exceptional hardness and mechanical strength.

Higher Density

Density is a direct measure of mass per unit volume. By removing the empty pore volume from the initial powder compact, the process inherently and significantly increases the final density of the alumina ceramic.

Low Thermal and Electrical Conductivity

A dense, pore-free structure is a superior insulator. Heat transfer (via phonons) and electrical current (via electrons) are disrupted by the tightly bonded, ordered crystal structure of sintered alumina. Eliminating pores, which could allow for heat transfer via convection, further enhances its insulating properties, making it ideal for high-temperature applications like furnace tubes and electrical standoffs.

Understanding the Trade-offs and Critical Parameters

Sintering is a balancing act. The final properties are not guaranteed and depend entirely on the control of key variables.

The Risk of Abnormal Grain Growth

If the sintering temperature is too high or the heating time is too long, a few grains can begin to grow very large at the expense of smaller ones. This abnormal grain growth can be detrimental, as larger grains can sometimes lead to lower fracture toughness.

The Importance of Temperature and Time

The sintering temperature and duration are the primary levers for controlling the process. An engineer must find the precise combination that achieves full densification while preventing excessive grain growth to optimize the final properties.

The Role of Powder Quality

The process starts with the powder. The initial particle size, shape, and distribution of the alumina powder have a profound impact on the final microstructure. Finer, more uniform powders generally lead to a more uniform, dense final product.

Making the Right Choice for Your Goal

Understanding the sintering process helps you evaluate the quality and suitability of an alumina ceramic component for your specific needs.

- If your primary focus is maximum mechanical strength: Look for ceramics with a fine, uniform grain structure, which indicates a well-controlled sintering process that avoided abnormal grain growth.

- If your primary focus is high-temperature insulation: Prioritize ceramics with the highest possible density (lowest porosity), as this minimizes pathways for thermal and electrical conduction.

- If you are evaluating a manufacturing process: Pay close attention to the control over sintering temperature and atmosphere, as these are the primary levers for tuning final properties.

Ultimately, mastering sintering is what transforms a simple powder into a high-performance engineered material.

Summary Table:

| Property Enhancement | Key Mechanism | Result |

|---|---|---|

| Increased Hardness & Strength | Solid-state diffusion fuses particles, eliminating pores | Enhanced mechanical durability and resistance to stress |

| Higher Density | Pore elimination and grain consolidation | Improved mass per unit volume and structural integrity |

| Low Thermal & Electrical Conductivity | Dense, pore-free structure disrupts heat and current flow | Superior insulation for high-temperature and electrical uses |

Unlock the full potential of your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise sintering processes to meet your unique experimental needs, enhancing material properties for superior results. Contact us today to discuss how we can optimize your ceramic production and drive innovation in your research!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide