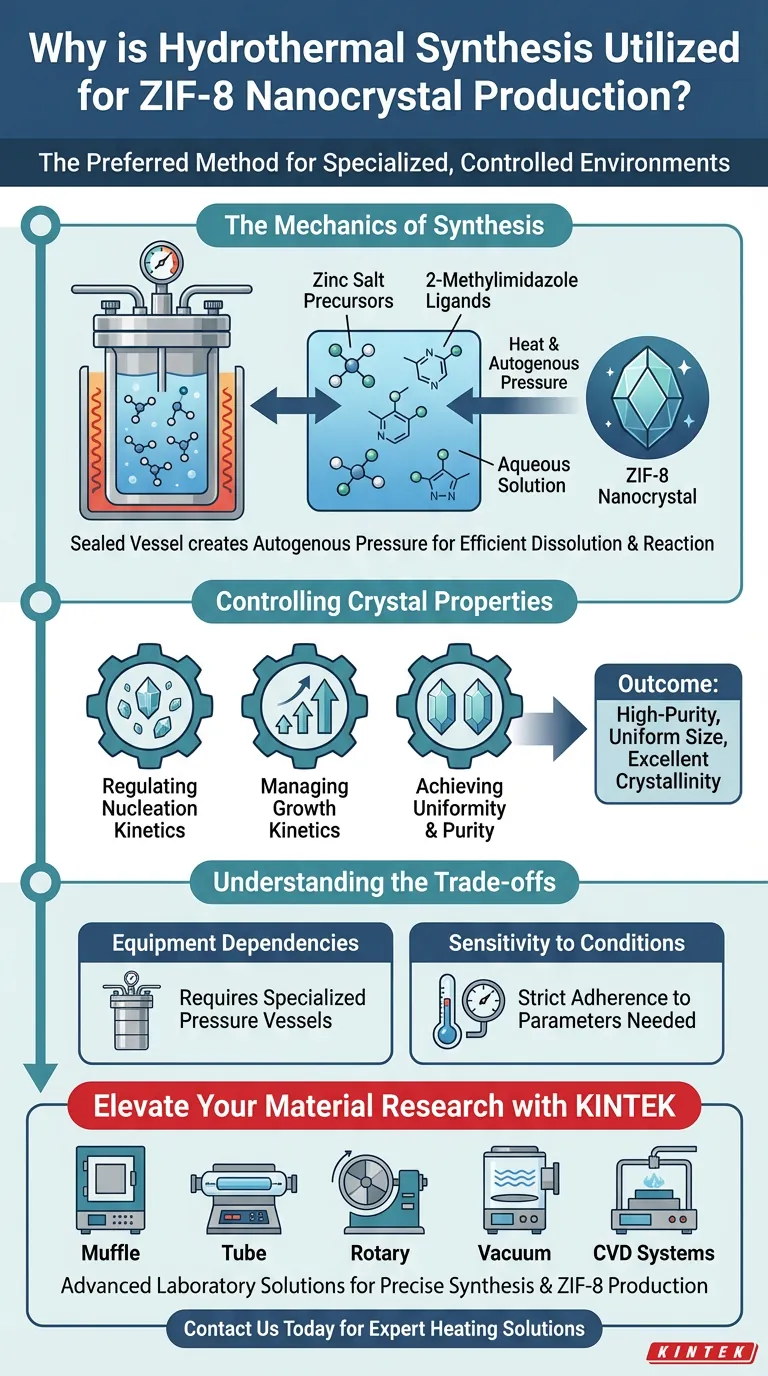

Hydrothermal synthesis is the preferred method for ZIF-8 production because it creates a specialized environment of controlled temperature and autogenous pressure within a sealed vessel. This setup allows for the efficient dissolution and reaction of zinc salt precursors and 2-methylimidazole ligands in aqueous solutions. By strictly regulating these conditions, the method dictates the kinetics of nucleation and growth to produce high-quality nanocrystals.

By leveraging the high-pressure environment of a closed system, hydrothermal synthesis offers superior control over crystal formation, resulting in high-purity ZIF-8 nanoparticles with uniform size and excellent crystallinity.

The Mechanics of Synthesis

Creating the Ideal Environment

The core advantage of this method lies in the use of a closed vessel. Unlike open-air reactions, this seals the chemical components inside.

Utilizing Autogenous Pressure

As the temperature rises within this sealed environment, autogenous pressure builds up naturally. This pressure is critical for driving the reaction forward.

Facilitating Efficient Reactions

The combination of heat and pressure allows the reagents—specifically zinc salt precursors and 2-methylimidazole ligands—to dissolve effectively. This ensures they react efficiently within the aqueous solution.

Controlling Crystal Properties

Regulating Nucleation Kinetics

Hydrothermal synthesis provides precise authority over nucleation, the initial step where the crystal begins to form.

Managing Growth Kinetics

Beyond the initial formation, the method allows for the control of growth kinetics. This determines how large the crystals become after nucleation.

Achieving Uniformity and Purity

Because the kinetics are so tightly controlled, the resulting ZIF-8 nanocrystals exhibit a uniform size distribution. Furthermore, the process yields nanoparticles that are both high-purity and highly crystalline.

Understanding the Trade-offs

Equipment Dependencies

The necessity of a closed vessel to generate autogenous pressure means this process cannot be performed in standard open glassware. Specialized equipment capable of withstanding pressure is required.

Sensitivity to Conditions

Since the outcome depends on precise control of the environment, deviations in temperature or seal integrity can disrupt the nucleation kinetics. This sensitivity requires strict adherence to process parameters to maintain uniformity.

Making the Right Choice for Your Goal

Hydrothermal synthesis is not just a mixing method; it is a tool for precision engineering at the nanoscale.

- If your primary focus is Crystal Quality: Hydrothermal synthesis provides the high purity and crystallinity necessary for advanced material applications.

- If your primary focus is Consistency: This method ensures a uniform size distribution by strictly managing nucleation and growth kinetics.

By controlling the pressure and temperature in a closed system, you transform simple precursors into highly ordered, uniform ZIF-8 structures.

Summary Table:

| Feature | Hydrothermal Synthesis Benefit |

|---|---|

| Environment | Sealed vessel with autogenous pressure |

| Reaction Efficiency | Enhanced dissolution of zinc salts & 2-methylimidazole |

| Nucleation Control | Precise regulation of initial crystal formation |

| Growth Kinetics | Managed development for uniform size distribution |

| Product Quality | High purity and excellent crystallinity |

Elevate Your Material Research with KINTEK

Precise control over nucleation and growth kinetics requires reliable high-temperature and high-pressure equipment. At KINTEK, we specialize in providing advanced laboratory solutions tailored for sophisticated material synthesis.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all customizable to meet your unique ZIF-8 production needs.

Ready to achieve superior nanocrystal uniformity and purity? Contact us today to discover how our expert heating solutions can optimize your synthesis workflow!

Visual Guide

References

- Ashleigh M. Chester, Thomas D. Bennett. Loading and thermal behaviour of ZIF-8 metal–organic framework-inorganic glass composites. DOI: 10.1039/d4dt00894d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Spark Plasma Sintering SPS Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the typical applications for drying ovens? Essential Uses in Labs and Industry

- What is the purpose of silver paste coating for BCZT ceramics? Ensuring Precision in Electrical Performance Testing

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety

- How are magnetic stirrers and constant temperature drying ovens utilized in the wet chemical synthesis of copper selenide nanorods?

- What are the primary technical objectives of CoCrFeMnNi alloy annealing? Master Recrystallization & Phase Control

- Why is a 1200°C hold required for Ti(C,N)-FeCr sintering? Unlock Superior Material Density

- What is the role of a rod mill during magnesite ore grinding? Achieve Optimal Flotation & Purification

- Why is a vacuum drying oven essential in the synthesis of CuCl nano-arrays? Protect Purity and Performance