In the flotation and purification of magnesite ore, the rod mill's primary role is to perform a specialized type of grinding called selective grinding. This process carefully reduces the ore to a uniform particle size ideal for the subsequent flotation stage, crucially preventing the material from being ground too finely, which would hinder the entire purification process.

The rod mill isn't just a crusher; it's a precision instrument. Its unique grinding action is essential for achieving the optimal particle size distribution that allows valuable magnesite to be efficiently separated from waste material during flotation.

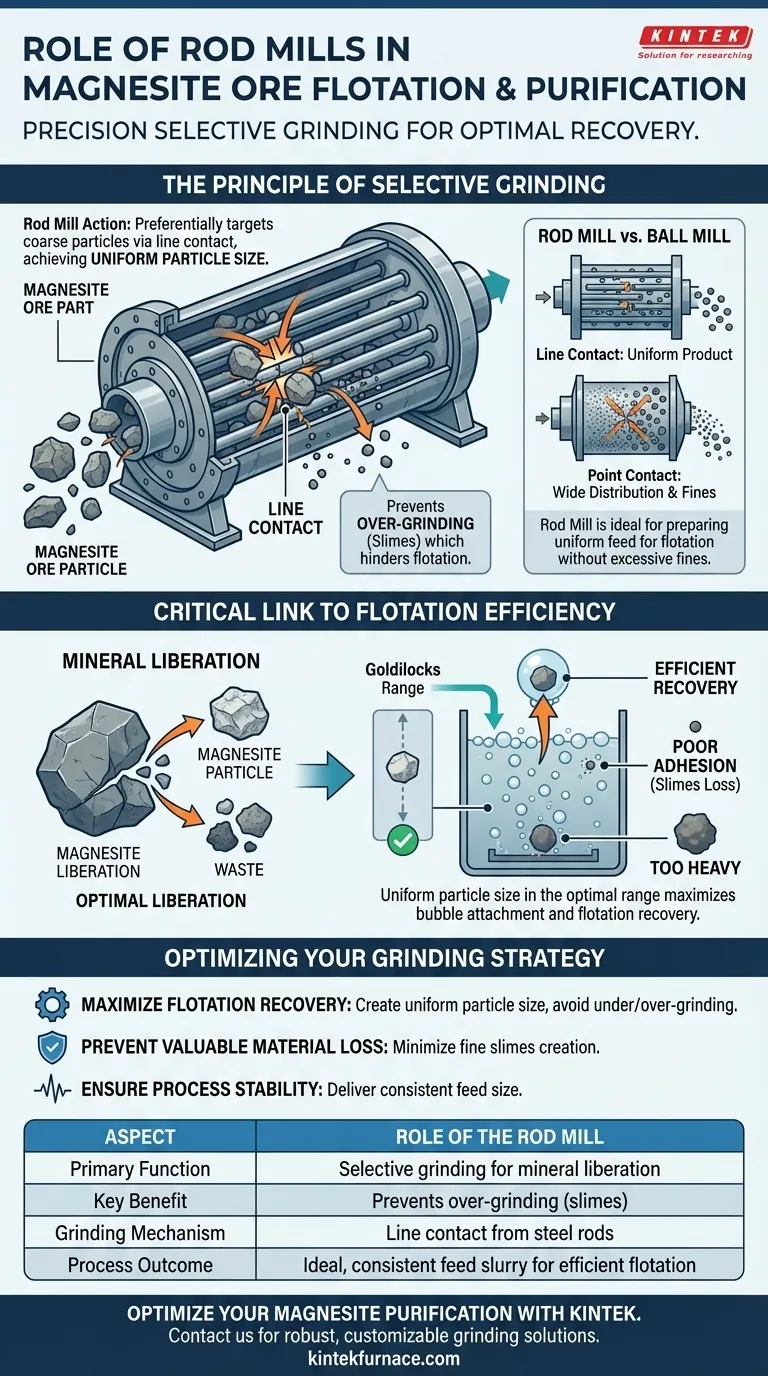

The Principle of Selective Grinding

To understand the rod mill's importance, we must look beyond simply making rocks smaller. The goal is to create a specific product: a slurry with a consistent particle size where the target mineral is physically liberated from the waste rock.

How a Rod Mill Works

A rod mill functions using long steel rods as the grinding media. As the mill rotates, these rods create line contact with the ore particles. This action preferentially targets the largest particles, breaking them down while having less effect on the smaller ones.

This mechanism acts like a screen, ensuring larger pieces are ground down before they exit the mill, which naturally results in a more uniform product.

The Problem of Over-Grinding

Over-grinding occurs when ore is broken down into ultra-fine particles, often called "slimes." These slimes are highly detrimental to the flotation process.

They consume excessive amounts of expensive chemical reagents and, due to their tiny mass, do not attach effectively to the air bubbles used in flotation. This leads to poor recovery and the loss of valuable magnesite.

Achieving a Uniform Particle Size

The selective nature of the rod mill is its greatest strength. By focusing its energy on the coarsest material, it effectively prevents the creation of excessive slimes and produces a slurry with a narrow, predictable particle size range. This consistency is the foundation for an efficient and stable flotation circuit.

The Critical Link to Flotation Efficiency

The grinding stage sets the success or failure of the entire purification process. The physical characteristics of the ground ore directly impact the chemical and physical separation that happens during flotation.

What is Mineral Liberation?

Mineral liberation is the core objective of grinding. It means breaking the ore just enough so that the individual magnesite mineral particles are separate from the unwanted waste minerals (gangue).

If the particles are not ground enough (under-grinding), the magnesite and gangue remain locked together, and separation is impossible. If they are ground too much (over-grinding), the problems mentioned earlier arise.

Why Particle Size Matters for Flotation

Flotation works by attaching air bubbles to specific mineral particles, causing them to float to the surface for collection. This process is highly sensitive to particle size.

Particles that are too large are too heavy for the bubbles to lift. Particles that are too small have poor adhesion and interfere with the process. The rod mill's ability to produce a uniform slurry within this optimal "Goldilocks" range is what makes it so critical for magnesite processing.

Understanding the Trade-offs

Choosing the right grinding equipment is a crucial engineering decision. While the rod mill is ideal for this application, it's important to understand its place relative to other technologies.

Rod Mills vs. Ball Mills

The primary alternative to a rod mill is a ball mill, which uses steel balls as grinding media. Ball mills create point contact, which is less selective and grinds all particles, leading to a much wider size distribution and a greater tendency to produce fines.

A ball mill is better suited for applications requiring a very fine final product, whereas a rod mill excels at preparing a uniform feed for processes like flotation without creating excessive slimes.

Limitations of a Rod Mill

A rod mill is not the ideal choice for producing extremely fine material. Its efficiency decreases as the target particle size becomes very small. For processes that demand an ultra-fine grind, a ball mill is often used in a secondary stage after the rod mill.

Optimizing Your Grinding Strategy

The choice and operation of your grinding circuit should be directly aligned with the goal of your downstream separation process.

- If your primary focus is maximizing flotation recovery: Use the rod mill to create a uniform particle size that avoids both under-grinding (poor liberation) and over-grinding (slimes).

- If your primary focus is preventing the loss of valuable material: Leverage the rod mill's selective grinding to minimize the creation of fine slimes that are difficult to recover in the flotation circuit.

- If your primary focus is process stability: Depend on the rod mill to deliver a consistent feed size to the flotation stage, which is the key to maintaining stable and predictable performance.

Ultimately, choosing a rod mill for magnesite grinding is a strategic decision to prepare the ore perfectly for the demands of flotation.

Summary Table:

| Aspect | Role of the Rod Mill |

|---|---|

| Primary Function | Performs selective grinding to liberate magnesite from waste rock. |

| Key Benefit | Prevents over-grinding (slimes) that hinders flotation recovery. |

| Grinding Mechanism | Uses line contact from steel rods for a more uniform particle size. |

| Process Outcome | Creates an ideal, consistent feed slurry for efficient flotation separation. |

Optimize your magnesite purification process with the right grinding solution.

The precise, selective grinding of a rod mill is critical for maximizing flotation recovery and minimizing valuable material loss. Backed by expert R&D and manufacturing, KINTEK offers robust and reliable rod mills, ball mills, and complete comminution systems, all customizable for your unique ore characteristics and plant requirements.

Contact us today to discuss how we can enhance your grinding circuit's efficiency and stability.

Get in touch via our Contact Form

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure