A laboratory high-temperature box furnace is essential for the synthesis of KNN ceramic powders because it provides the strictly controlled thermal environment required for calcination. This equipment supplies the sustained heat necessary to drive solid-state chemical reactions, ensuring raw materials are fully converted into the target crystal phase.

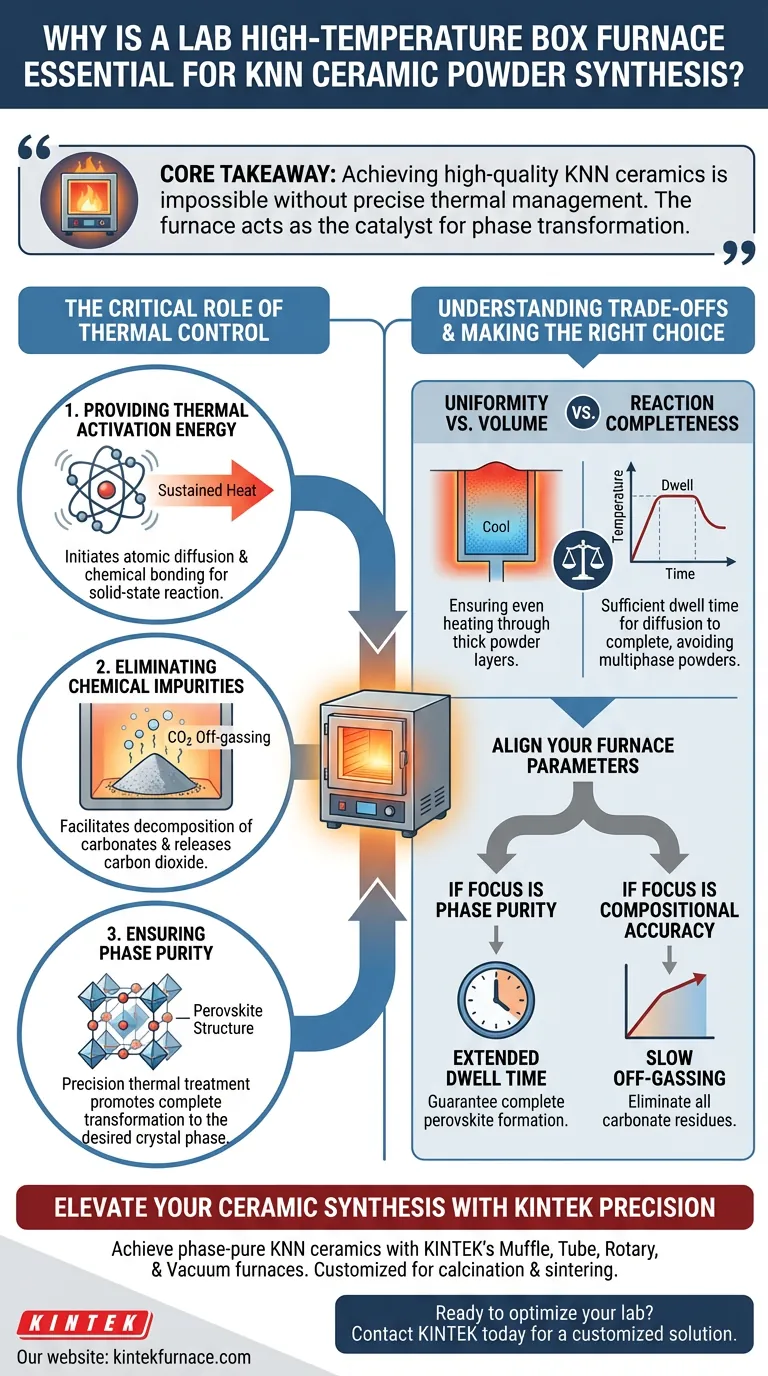

Core Takeaway Achieving high-quality (K, Na)NbO3 (KNN) ceramics is impossible without precise thermal management. The high-temperature box furnace acts as the catalyst for phase transformation, ensuring that raw carbonates and oxides evolve into a pure, complete perovskite structure through the efficient removal of byproducts.

The Critical Role of Thermal Control

The synthesis of KNN ceramic powders relies on a process called solid-state reaction. This is not merely mixing powders; it is a chemical transformation that requires significant thermal energy to occur.

Providing Thermal Activation Energy

Raw materials in their powder form are chemically stable at room temperature. To initiate a reaction, they require a specific amount of thermal activation energy.

The high-temperature box furnace provides this energy by maintaining precise temperatures for extended periods. This heat allows the atoms within the solid particles to diffuse and react with one another, forming new chemical bonds essential for the KNN compound.

Eliminating Chemical Impurities

A major function of the calcination process in the box furnace is the elimination of carbonates.

The raw materials often include carbonate compounds. As the furnace heats these materials, they undergo thermal decomposition. The furnace environment facilitates the release of carbon dioxide ($CO_2$) gas. If this step is not completed thoroughly, residual carbon can contaminate the final ceramic, degrading its electrical properties.

Ensuring Phase Purity

The ultimate goal of using the box furnace is to achieve a specific crystal structure known as the perovskite structure.

The thermal treatment promotes the transformation of the powder mixture into the (K, Na)NbO3 crystal phase. The precision of the furnace determines the phase purity of this precursor. A stable, uniform temperature ensures that the entire batch of powder converts to the desired phase without retaining unreacted raw materials or forming unwanted secondary phases.

Understanding the Trade-offs

While the high-temperature box furnace is the standard tool for this process, understanding its operational limits is vital for success.

Uniformity vs. Volume

A common challenge in solid-state synthesis is ensuring thermal uniformity. While the furnace generates high heat, the powder bed itself must be heated evenly. If the powder layer is too thick or the furnace has cold spots, the decomposition of carbonates may be incomplete in the center of the sample.

Reaction Completeness

The process relies on time-temperature interdependence. Setting the correct temperature is not enough; the material must dwell at that temperature long enough for the diffusion processes to complete. Cutting the dwell time short in a box furnace can lead to a multiphase powder that lacks the necessary structural integrity for subsequent sintering.

Making the Right Choice for Your Goal

When configuring your thermal treatment process for KNN powders, align your furnace parameters with your specific quality metrics.

- If your primary focus is Phase Purity: Ensure your process allows for an extended dwell time at the calcination temperature to guarantee the complete formation of the perovskite structure.

- If your primary focus is Compositional Accuracy: Prioritize a heating profile that allows for the slow, complete off-gassing of carbon dioxide to eliminate all carbonate residues before the final phase forms.

Precise thermal control is the difference between a mixture of raw oxides and a functional, high-performance piezoelectric ceramic.

Summary Table:

| Process Objective | Furnace Role | Key Benefit |

|---|---|---|

| Thermal Activation | Provides sustained high heat | Initiates atomic diffusion and chemical bonding |

| Decomposition | Facilitates CO2 off-gassing | Removes carbonates and chemical impurities |

| Phase Formation | Precise temperature control | Ensures complete perovskite crystal structure |

| Uniformity | Controlled heating environment | Prevents unreacted raw materials and cold spots |

Elevate Your Ceramic Synthesis with KINTEK Precision

Achieving phase-pure KNN ceramics requires the uncompromising thermal stability that only expert-engineered equipment can provide. KINTEK empowers researchers and manufacturers with high-performance Muffle, Tube, Rotary, and Vacuum furnaces designed for the rigors of solid-state synthesis.

Backed by industry-leading R&D, our laboratory high-temperature systems are fully customizable to meet your specific calcination and sintering requirements. Don't let thermal inconsistency compromise your material's piezoelectric properties.

Ready to optimize your lab's performance? Contact KINTEK today for a customized furnace solution.

Visual Guide

References

- Mingxiang Zhang, Fei Wang. Indium Doped Gan Porous Micro‐Rods Enhanced CO<sub>2</sub> Reduction Driving By Solar Light. DOI: 10.1002/admi.202301035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory high-temperature box furnace influence the microstructure of H13 steel? Expert Insights

- What thermal processes can be performed using Box Furnaces? Unlock Versatile Heat Treatment Solutions

- Why is temperature uniformity important in a muffle furnace? Ensure Precise and Reliable Results

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab

- How long does heating take on a muffle furnace? From 25 Minutes to Hours Explained

- What is a muffle furnace used for? Achieve Pure, High-Temperature Processing

- What temperature capabilities do modern Muffle Furnaces have? Achieve Precision Up to 1800°C

- What temperature ranges do different types of muffle furnaces operate at? Find Your Perfect Heat Solution