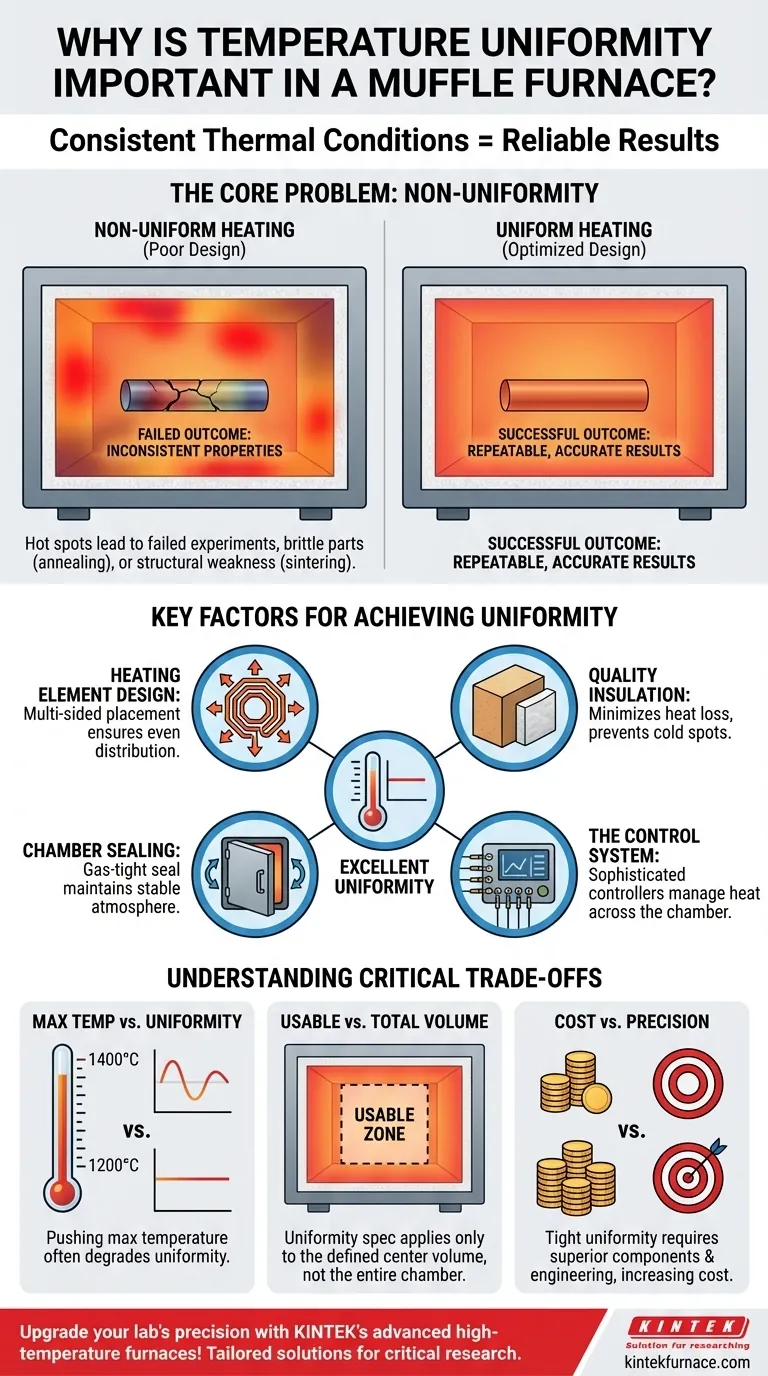

In any high-temperature process, temperature uniformity is the single most critical factor for achieving accurate and reliable outcomes. It ensures that every part of the material inside a muffle furnace is exposed to the exact same thermal conditions. Without it, processes like annealing or sintering will produce inconsistent, unpredictable, and often unusable results.

While a furnace's maximum temperature tells you what it can do, its temperature uniformity tells you how well it can do it. A lack of uniformity is the primary source of failed experiments and inconsistent material properties.

The Core Problem: Gradients and Inconsistent Results

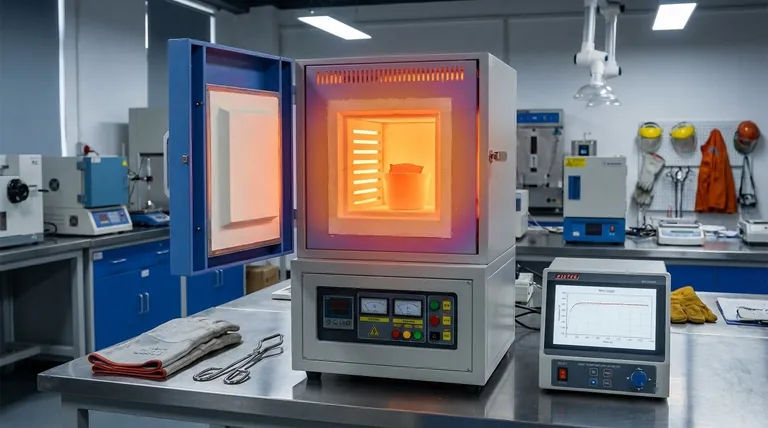

A muffle furnace is designed to create a perfectly controlled thermal environment. However, physical realities mean that temperature can vary from one point in the chamber to another. Understanding and controlling this variation is key.

What is Temperature Uniformity?

Temperature uniformity is a specification that defines the maximum temperature variation within the usable volume of the furnace chamber. It is often expressed as a plus-or-minus value, such as ±5°C, at a specific setpoint temperature.

Think of a conventional oven with "hot spots." A high-quality muffle furnace is engineered to eliminate these spots, ensuring the temperature at the front of the chamber is identical to the temperature at the back.

How Non-Uniformity Ruins a Process

When heat is not distributed evenly, different parts of your sample undergo different treatments. This leads directly to failed outcomes.

For annealing or tempering, some sections of a metal part might become perfectly softened while others remain brittle and untreated.

For sintering ceramics, non-uniform heating results in varying density and porosity across the part, leading to structural weakness and a failed component.

Ultimately, poor uniformity means your results are not repeatable, wasting time, energy, and valuable materials.

Key Factors That Determine Uniformity

Achieving excellent temperature uniformity is a complex engineering challenge that depends on the furnace's fundamental design and components.

Heating Element Design

The placement and quality of heating elements are paramount. Furnaces with heating elements on multiple sides (e.g., sides, top, and bottom) provide much more even heat distribution than those with elements only in one location.

Quality of Insulation

High-performance insulation, such as dense refractory brick or ceramic fiber, is crucial. It minimizes heat loss to the outside environment, which prevents cold spots from forming near the chamber walls and door.

Chamber Sealing

A tight seal is essential for maintaining a stable internal atmosphere. Gas-tight doors prevent cooler ambient air from entering and creating drafts, which would immediately disrupt the temperature balance inside the chamber.

The Control System's Role

A standard control system uses a single thermocouple to measure the temperature at one point. It then cycles the power to maintain that single point at the set temperature.

Achieving true uniformity requires more sophisticated controllers that can manage heat distribution across the chamber, often informed by data from multiple thermocouples and advanced heating element design.

Understanding the Trade-offs

When selecting or using a muffle furnace, you must look beyond the headline features and consider the critical trade-offs that impact performance.

Maximum Temperature vs. Uniformity

A furnace may be rated to reach 1400°C, but its specified uniformity might only be guaranteed up to a lower temperature, like 1200°C. Pushing a furnace to its absolute maximum often degrades its ability to hold a uniform temperature.

Usable Volume vs. Total Volume

A uniformity specification of ±5°C almost never applies to the entire chamber. It applies to a smaller, defined usable volume, typically in the center. Placing samples too close to the door, walls, or thermocouple can expose them to temperatures outside the uniform zone.

Cost vs. Precision

There is a direct correlation between price and performance. Achieving tight temperature uniformity requires superior insulation, more complex heating systems, and advanced controllers, all of which increase the cost of the furnace.

Making the Right Choice for Your Process

The level of temperature uniformity you need is directly tied to the sensitivity of your application.

- If your primary focus is critical material science (annealing, sintering, or research): Prioritize a furnace with a tight, certified temperature uniformity specification (e.g., ±3-5°C) across its primary working range.

- If your primary focus is general lab work (ashing, drying, simple heat treating): A standard furnace with a less stringent uniformity specification (e.g., ±10-15°C) may be sufficient and more cost-effective.

- When evaluating any furnace: Always look beyond the maximum temperature and ask for the uniformity specification, the volume it applies to, and the temperature at which it was measured.

Ultimately, understanding temperature uniformity is the difference between simply heating a sample and precisely engineering a material.

Summary Table:

| Aspect | Impact on Uniformity |

|---|---|

| Heating Element Design | Multi-sided elements ensure even heat distribution |

| Insulation Quality | High-performance materials prevent cold spots |

| Chamber Sealing | Gas-tight seals maintain stable internal atmosphere |

| Control System | Advanced controllers manage heat across the chamber |

| Trade-offs | Max temperature, usable volume, and cost affect performance |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met with superior temperature uniformity and reliability. Contact us today to discuss how our furnaces can enhance your material science processes and deliver consistent, repeatable results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO