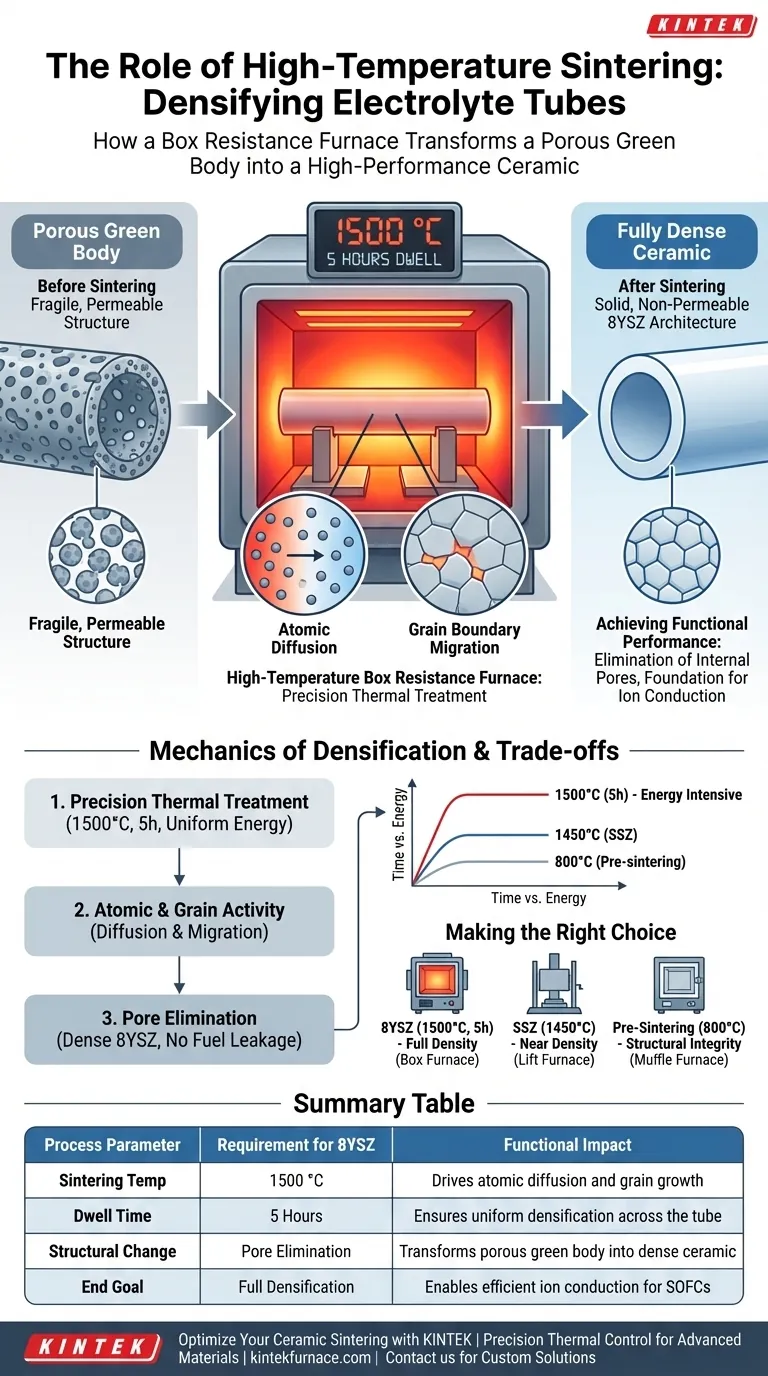

A high-temperature box resistance furnace acts as the primary vessel for structural densification in the manufacturing of electrolyte support tubes. It provides a sustained thermal environment of 1500 °C for a continuous 5-hour period, driving the atomic diffusion and grain boundary migration necessary to transform a porous green body into a solid, fully dense ceramic capable of high-performance ion conduction.

The furnace does not simply heat the material; it fundamentally restructures it. By eliminating internal pores through precise thermal control, it creates the dense 8YSZ (Yttria-Stabilized Zirconia) architecture required for the efficient operation of Solid Oxide Fuel Cells (SOFCs).

The Mechanics of Densification

Precision Thermal Treatment

The core function of this furnace is to maintain a stable 1500 °C environment.

Unlike pre-sintering stages that might occur at lower temperatures (around 800 °C), this high-temperature phase is where the final material properties are locked in.

The furnace maintains this temperature for 5 hours, ensuring the entire electrolyte tube receives uniform thermal energy.

Atomic Diffusion and Migration

At these elevated temperatures, the ceramic particles within the "green body" (the unfired tube) become active.

The furnace facilitates atomic diffusion, where atoms move from areas of high concentration to low concentration.

Simultaneously, it promotes grain boundary migration, allowing the ceramic grains to grow and bond. This is the mechanism that physically closes the gaps between particles.

Achieving Functional Performance

Elimination of Internal Pores

The primary physical change driven by the furnace is the removal of porosity.

As the grain boundaries migrate, the internal pores are eliminated.

This transforms the tube from a fragile, permeable structure into a fully dense ceramic. This density is critical because any remaining porosity could allow fuel gases to leak, destroying the cell's efficiency.

Foundation for Ion Conduction

The ultimate goal of this sintering process is electrochemical performance.

The dense structure created by the furnace provides the physical pathway for ion conduction.

Without the complete densification provided by the 1500 °C treatment, the 8YSZ electrolyte would lack the structural integrity to support the ion transport required for Solid Oxide Fuel Cells (SOFCs).

Understanding the Trade-offs

Time vs. Energy Consumption

Achieving full density in 8YSZ requires significant energy input over a long duration.

While a 5-hour hold at 1500 °C guarantees densification, it is an energy-intensive process compared to lower-temperature pre-sintering or processing alternative materials like SSZ (which may sinter at 1450 °C).

Material Specificity

It is crucial to match the furnace parameters to the specific material chemistry.

While a box resistance furnace at 1500 °C is ideal for 8YSZ, other materials like SSZ or Li-based compounds may require different thermal profiles (e.g., 1450 °C or 1143 K) or different furnace types (such as lift or tube furnaces) to prevent phase degradation or over-sintering.

Making the Right Choice for Your Goal

To ensure optimal performance of your electrolyte tubes, align your thermal processing with your specific material requirements:

- If your primary focus is 8YSZ Electrolyte Tubes: Utilize a box resistance furnace capable of sustaining 1500 °C for at least 5 hours to ensure complete pore elimination.

- If your primary focus is SSZ Electrolytes: Consider that a slightly lower temperature (1450 °C) in a lift furnace may be sufficient for densification near theoretical density.

- If your primary focus is Pre-Sintering: Use a standard muffle furnace at lower temperatures (approx. 800 °C) to establish structural integrity before the final high-temperature firing.

The success of your SOFC depends entirely on the density of the electrolyte, making the stability and temperature capacity of your furnace the deciding factor in cell efficiency.

Summary Table:

| Process Parameter | Requirement for 8YSZ | Functional Impact |

|---|---|---|

| Sintering Temp | 1500 °C | Drives atomic diffusion and grain growth |

| Dwell Time | 5 Hours | Ensures uniform densification across the tube |

| Structural Change | Pore Elimination | Transforms porous green body into dense ceramic |

| End Goal | Full Densification | Enables efficient ion conduction for SOFCs |

Optimize Your Ceramic Sintering with KINTEK

Precision thermal control is the difference between a porous failure and a high-performance electrolyte. KINTEK provides industry-leading Muffle, Tube, and Box Resistance Furnaces engineered to sustain the rigorous 1500 °C environments required for advanced material densification.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique thermal profiles of 8YSZ, SSZ, and other specialized ceramics.

Ready to elevate your lab's output? Contact us today to find your custom furnace solution.

Visual Guide

References

- Zeyu Lin, Bo Liang. Ammonia-Fueled Tubular Solid Oxide Fuel Cell Using a Plasma-Enhanced Cracking Reactor. DOI: 10.1021/acs.energyfuels.5c03027

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the maximum temperature in the muffle furnace? From 1200°C to 1800°C+ Solutions

- Why are muffle furnaces important in quality control? Ensure Product Integrity with Controlled Heat Testing

- How does a high-precision programmable muffle furnace improve creep testing? Ensure Accuracy in Titanium Alloys

- What applications does a muffle furnace have in coal quality analysis? Essential for Precise Coal Testing

- What role does a laboratory oven play in lignin nanofiber stabilization? Unlock Precision Thermal Cross-linking

- What role does a muffle furnace play in simulating cement clinker? Achieve High-Precision Lab Sintering Today

- What role does a high-temperature box-type resistance furnace play in solar cell electrode processing? Master Sintering

- What are the main industries that use muffle furnaces? Essential for Clean Heat in Labs and Manufacturing