In coal quality analysis, a muffle furnace is an indispensable tool used to perform a series of standardized tests. It is essential for determining the foundational characteristics of coal, including its moisture content, the amount of volatile matter it releases, and its final ash content after complete combustion. These measurements are fundamental to assessing the coal's quality, grade, and commercial value.

The core function of a muffle furnace is not simply to generate high heat. Its true value lies in providing a precisely controlled and uniform thermal environment, which is the non-negotiable requirement for producing the repeatable and accurate data that underpins coal contract specifications and power plant operations.

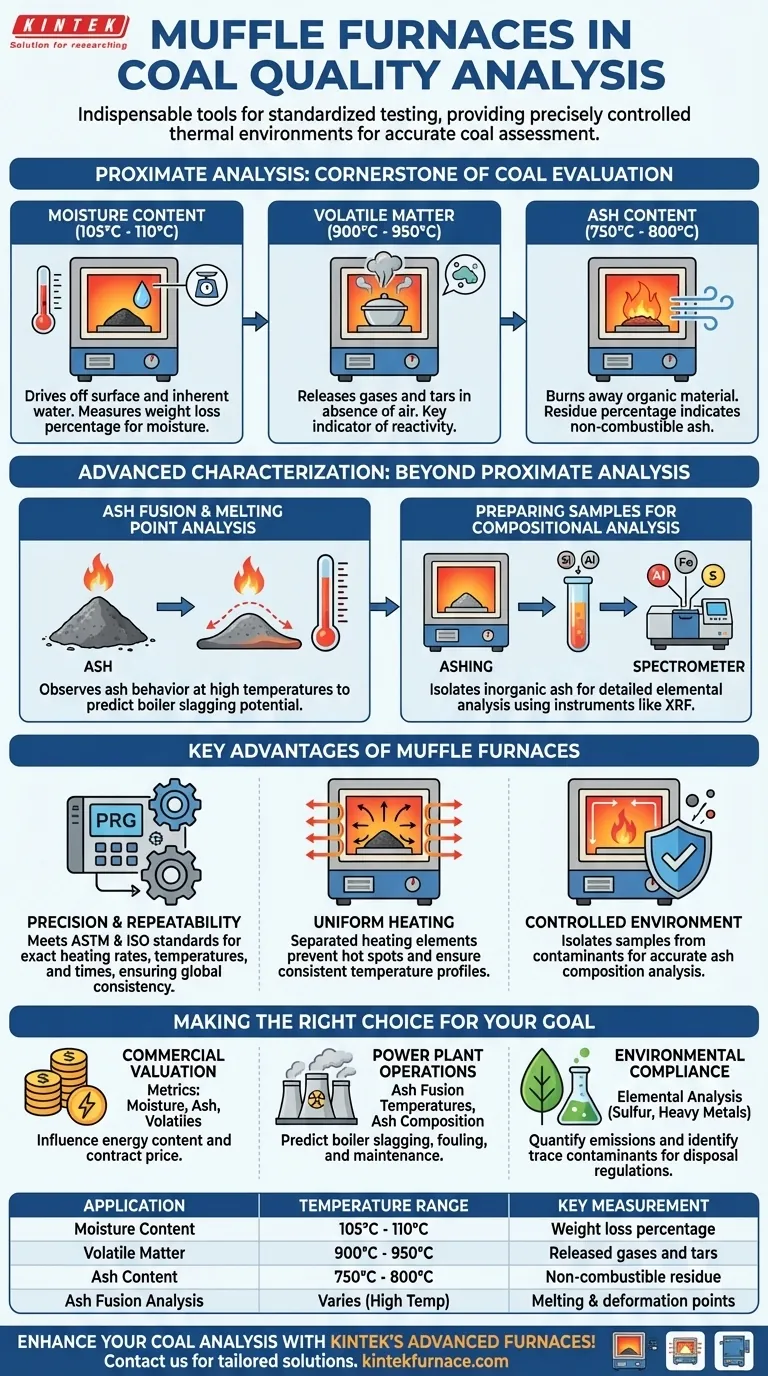

The Furnace's Role in Proximate Analysis

Proximate analysis is the cornerstone of coal evaluation, breaking down its composition into four key categories. A muffle furnace is used to determine the first three: moisture, volatile matter, and ash.

Determining Moisture Content

The first step in analysis is to determine the amount of surface and inherent moisture in a coal sample.

A sample is heated in the muffle furnace to a relatively low, controlled temperature, typically between 105°C and 110°C. This temperature is high enough to drive off water but low enough to prevent the coal itself from combusting. The weight difference before and after heating reveals the moisture percentage.

Isolating Volatile Matter

Volatile matter refers to the gases and tars that are driven off when coal is heated without air. This is a key indicator of a coal's reactivity and how it will behave during combustion.

To measure this, a coal sample is placed in a covered crucible and heated in the furnace to a precise high temperature, often 900°C or 950°C, for a set period. The cover prevents the sample from burning, ensuring that only the volatile components are released.

Quantifying Ash Content

Ash is the non-combustible, inorganic residue left over after coal is completely burned. High ash content reduces the energy value of coal and increases disposal costs.

The furnace is used to heat an uncovered coal sample to a temperature of 750°C to 800°C. With an ample supply of air, all organic material burns away, leaving only the ash. The weight of this residue, expressed as a percentage of the original sample weight, is the ash content.

Advanced Characterization Using the Furnace

Beyond proximate analysis, the muffle furnace is a critical preparatory tool for understanding how coal will behave in an industrial boiler.

Ash Fusion and Melting Point Analysis

The behavior of ash at high temperatures is critical for power plant operators. Ash that melts at low temperatures can form hard, glassy deposits known as slag on boiler walls, reducing efficiency and requiring costly cleaning.

To test this, the ash previously created in the furnace is pressed into a small cone. This cone is then heated inside the furnace while being observed. The temperatures at which it begins to deform, soften, and melt—known as ash fusion temperatures—are recorded to predict its slagging potential.

Preparing Samples for Compositional Analysis

The specific chemical makeup of the ash dictates its melting behavior and environmental impact.

A muffle furnace is used for ashing—the controlled process of burning off all organic material to isolate the inorganic ash. This purified ash sample is then taken to other instruments (like an X-Ray Fluorescence spectrometer) for a detailed elemental analysis to determine the concentration of minerals like silica, alumina, iron, and sulfur.

Understanding the Key Advantages

Using a specialized muffle furnace is not arbitrary; it is a requirement for achieving reliable and legally defensible results in coal trading and utilization.

The Mandate for Precision and Repeatability

Coal is a global commodity traded based on specifications defined by standards organizations like ASTM and ISO. These standards dictate exact heating rates, temperatures, and times. A muffle furnace's programmable controller is the only way to meet these stringent requirements, ensuring that results are repeatable anywhere in the world.

Uniform Heating Without Direct Flame

The term "muffle" refers to the furnace's design, where the heating elements are physically separated from the internal chamber. This ensures the sample is heated by uniform radiation and convection, not by direct flame impingement. This prevents "hot spots" and guarantees the entire sample experiences the same temperature profile, which is crucial for accurate results.

A Controlled, Contaminant-Free Environment

The sealed chamber of the furnace isolates the sample from airborne contaminants in the lab. This is critical for ash composition analysis, where even trace amounts of foreign material could skew the results. It provides a clean, controlled environment for thermal processing.

Making the Right Choice for Your Goal

The data generated using a muffle furnace serves different purposes. Understanding your primary objective will help you focus on the most relevant metrics.

- If your primary focus is commercial valuation: Proximate analysis results (moisture, ash, volatiles) are paramount as they directly influence the coal's energy content and contract price.

- If your primary focus is power plant operations: Ash fusion temperatures and ash composition are the most critical outputs, as they predict boiler slagging, fouling, and maintenance requirements.

- If your primary focus is environmental compliance: Preparing ash samples for elemental analysis is key to quantifying sulfur content for emissions control and identifying trace heavy metals for ash disposal regulations.

Ultimately, mastering the applications of the muffle furnace provides a complete and defensible picture of a coal's quality from the mine to its final use.

Summary Table:

| Application | Temperature Range | Key Measurement |

|---|---|---|

| Moisture Content | 105°C - 110°C | Weight loss percentage |

| Volatile Matter | 900°C - 950°C | Released gases and tars |

| Ash Content | 750°C - 800°C | Non-combustible residue |

| Ash Fusion Analysis | Varies (high temp) | Melting and deformation points |

Enhance your coal analysis with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, improving accuracy and efficiency in coal quality testing. Contact us today to discuss how our products can benefit your operations and deliver reliable, defensible results for commercial valuation, power plant operations, or environmental compliance.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity