High-precision programmable muffle furnaces are essential for isolating material behavior during the long-duration stress tests required for titanium alloys. By utilizing multi-zone monitoring systems, these furnaces maintain a stable thermal environment up to 1200 °C, ensuring that the specimen is subjected to consistent heat with minimal fluctuation over hundreds of hours.

The primary value of a high-precision furnace in creep testing is the elimination of temperature drift. By removing thermal expansion and contraction as variables, researchers can confirm that measured deformation is caused solely by the material's creep response, allowing for the accurate calculation of steady-state creep rates.

The Critical Role of Thermal Stability

Eliminating Environmental Noise

Creep testing measures how a material deforms under a constant load over a long period. Because metals expand and contract with heat, even minor temperature changes can register as false "strain" in the data.

High-precision muffle furnaces mitigate this risk by providing an industrial-grade, stable environment. This stability is maintained over the hundreds of hours required to reach steady-state creep.

Ensuring Uniform Heating

Titanium alloys produced by additive manufacturing often have complex microstructures. To test them accurately, the entire gauge length of the specimen must be at the exact same temperature.

These furnaces employ multi-zone monitoring systems. This technology actively detects and corrects temperature gradients, ensuring the top, middle, and bottom of the sample experience identical thermal conditions.

Technical Mechanisms for Accuracy

Programmable Profiles for Consistency

Creep testing often requires specific ramp-up and hold times to reach the testing temperature without shocking the material. Programmable furnaces allow users to define these heating curves with exact precision.

This repeatability ensures that every specimen in a batch is tested under identical thermal histories. It reduces the standard deviation in test results caused by operator error or manual heating adjustments.

Supporting High-Temperature Regimes

Titanium alloys are frequently used in aerospace and medical applications where high heat is a factor. These furnaces are capable of sustaining temperatures up to 1200 °C.

This capacity allows researchers to test the alloy well beyond its standard service temperature. It provides critical data on failure modes and safety margins under extreme conditions.

Understanding the Trade-offs and Limitations

The Challenge of Oxidation

While the primary reference highlights thermal stability, it is critical to note that standard muffle furnaces often heat in an air atmosphere. Titanium is highly reactive to oxygen at high temperatures (above roughly 400-500 °C).

Exposure to air can cause surface oxidation or "alpha-case" formation, which makes the surface brittle. This can lead to premature cracking that mimics creep failure but is actually a chemical degradation issue.

Atmosphere Control vs. Temperature Stability

If your muffle furnace lacks a controlled atmosphere capability, you risk compromising the surface integrity of the titanium.

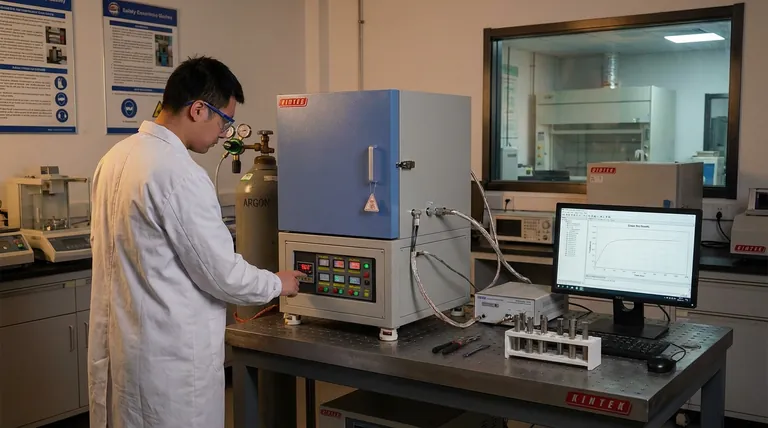

In contrast, equipment like Tube Furnaces (noted in supplementary data) often prioritize inert gas flow (Argon) to prevent decarburization. When using a muffle furnace for titanium, you must verify if it can support an inert gas retort or if the oxidation is acceptable for your specific test parameters.

Making the Right Choice for Your Goal

To ensure your creep testing data is valid for additive manufacturing applications, weigh your equipment capabilities against your data requirements.

- If your primary focus is determining the Steady-State Creep Rate: Prioritize a muffle furnace with multi-zone monitoring to guarantee that thermal drift does not skew your strain measurements over long durations.

- If your primary focus is Phase Transformation and Surface Integrity: Ensure your furnace solution includes inert gas purging (like Argon) to prevent oxidation from altering the material properties during the test.

Accuracy in creep testing ultimately relies on controlling the environment so that the only variable changing is the material's physical structure under load.

Summary Table:

| Feature | Benefit for Creep Testing | Impact on Accuracy |

|---|---|---|

| Multi-Zone Monitoring | Eliminates temperature gradients across the sample | Ensures uniform deformation data |

| Programmable Profiles | Consistent ramp-up and thermal history | Increases repeatability across test batches |

| Thermal Stability | Prevents false strain from thermal expansion | Isolates material creep from environmental noise |

| High-Temp Capability | Testing up to 1200 °C | Validates safety margins for aerospace applications |

Elevate Your Material Testing Accuracy with KINTEK

Precise data starts with a stable thermal environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet the rigorous demands of additive manufacturing research.

Whether you need multi-zone temperature control to eliminate drift or inert atmosphere integration to prevent titanium oxidation, our lab high-temp furnaces provide the stability your research deserves.

Ready to optimize your testing workflow? Contact us today to discuss your custom furnace solution.

References

- Creep Behavior and Model Comparison for Ti–6Al–4V Alloy Produced via Electron Beam Powder Bed Fusion. DOI: 10.1007/s11661-025-07953-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a muffle furnace during carbonization? Master Coffee-Based Bio-Adsorbent Production

- What temperature does a muffle furnace control? From 100°C to 1800°C+ for Your Specific Process

- What are the temperature capabilities of a lab muffle furnace? Find the Right Heat for Your Lab Needs

- What temperature ranges can muffle furnaces achieve? Find the Perfect Heat for Your Lab Needs

- What safety feature is included in muffle furnaces to protect operators? Essential Safeguards for Lab Safety

- What is the function of a muffle furnace during Cu–Ce/HZSM-5 production? Optimize Calcination & Regeneration Stages

- What role does a Muffle furnace play in chemical reactions? Achieve Precise, Contamination-Free Thermal Processing

- What role does a high-temperature muffle furnace play in the preparation of a BiVO4 seed layer? Expert Synthesis Guide