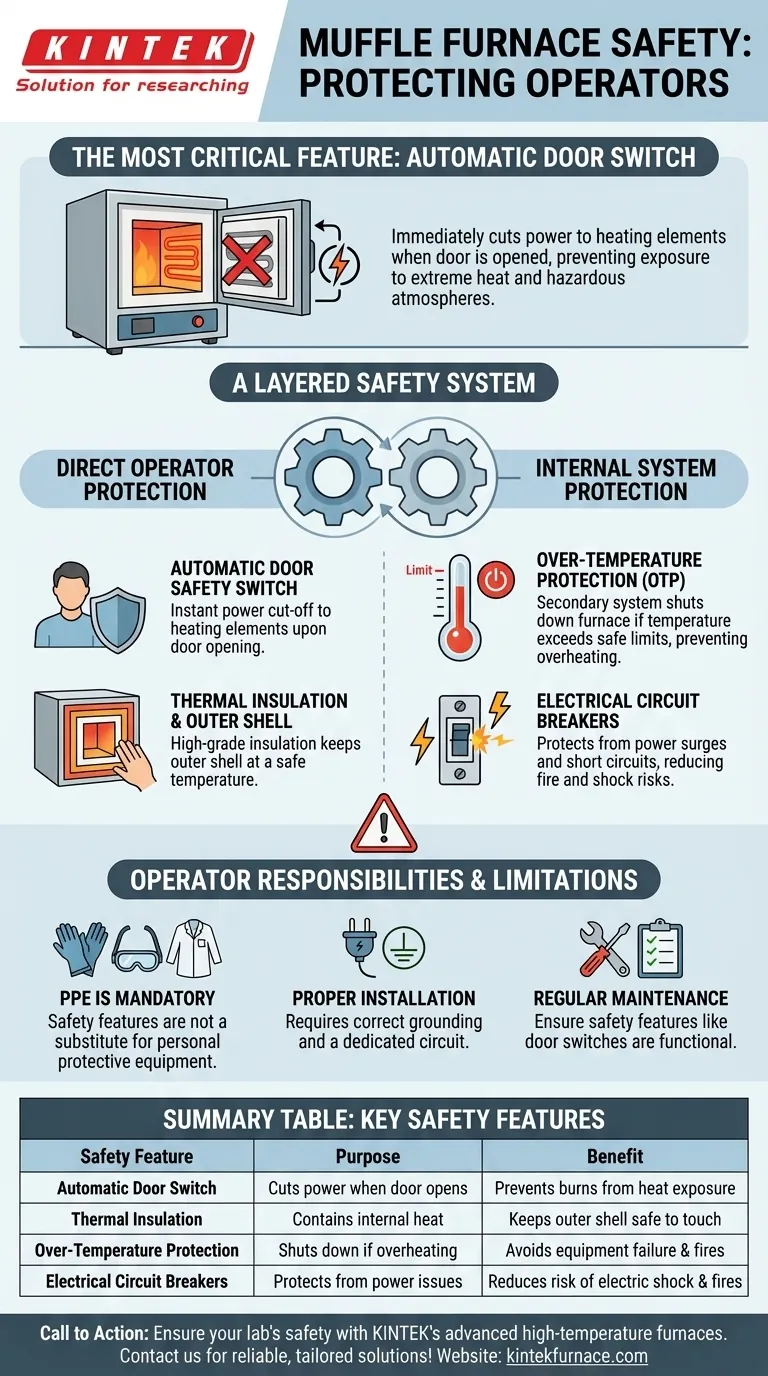

The most critical safety feature designed to directly protect operators of a muffle furnace is the automatic door switch. This interlock mechanism immediately cuts power to the heating elements the moment the furnace door is opened, preventing accidental exposure to the extreme internal temperatures and any potentially hazardous atmospheres within the chamber.

Muffle furnace safety is not reliant on a single component, but a layered system. It combines direct operator safeguards like door interlocks with internal controls that prevent catastrophic equipment failure, ensuring protection from thermal, electrical, and atmospheric hazards.

Direct Operator Protection: The First Line of Defense

These features are designed to prevent immediate physical harm to the person operating the furnace. They act as the most direct barrier between the user and the high-energy environment inside.

The Automatic Door Safety Switch

This is a non-negotiable safety interlock. When the door is opened, the switch breaks the electrical circuit to the heating elements. This instantly stops the heating process, protecting you from radiant heat and direct contact with high-temperature components.

Thermal Insulation and Outer Shell

Muffle furnaces are constructed with multiple layers of high-grade insulation. This material contains the extreme heat within the chamber, ensuring the outer shell remains at a safe temperature to prevent accidental burns from contact.

Internal System Protection: Preventing Catastrophic Failure

These automated systems work in the background to keep the furnace operating within safe limits. They protect the equipment itself from self-destruction, which in turn prevents a hazardous situation for the operator.

Over-Temperature Protection (OTP)

This is a secondary, independent control system that monitors the furnace's temperature. If the primary controller fails and the temperature rises above a pre-set safety limit, the OTP will shut down the furnace completely, preventing overheating that could damage the unit or create a fire hazard.

Electrical Circuit Breakers

Integrated circuit breakers and fuses are fundamental electrical safeguards. They protect the furnace from power surges and short circuits, automatically cutting power to prevent electrical fires and protect the operator from the risk of electric shock.

Understanding the Limitations and Operator Responsibilities

While modern furnaces have robust safety systems, they do not eliminate the need for proper procedure and awareness. Relying on features alone is a critical mistake.

Safety Features vs. Safe Practices

Built-in features are a failsafe, not a substitute for correct personal protective equipment (PPE). Always wear appropriate heat-resistant gloves, safety glasses, and lab coats when handling items or operating the furnace.

The Importance of Proper Installation

A furnace's safety is compromised if it is not installed correctly. It must be properly grounded to prevent electric shock and connected to a dedicated circuit capable of handling its power draw. Overloading a circuit is a significant fire risk.

Maintenance is Non-Negotiable

Safety features like door switches and over-temperature controllers must be checked regularly to ensure they are functional. A faulty or bypassed safety switch creates a serious and often invisible hazard.

Making the Right Choice for Your Application

Your operational safety depends on ensuring the right features are present and functional for your specific task.

- If your primary focus is routine heating of non-volatile materials: Prioritize a functional door switch and verify the over-temperature protection is set correctly.

- If your primary focus is working with materials that release fumes: You must use a furnace specifically equipped with an exhaust port or ventilation system, and operate it within a fume hood.

- If you are installing a new furnace: Insist on professional confirmation of proper electrical grounding and connection to a dedicated power circuit to prevent electrical hazards.

Ultimately, a safe laboratory environment is achieved by combining the furnace's engineered safety features with diligent and informed operator practices.

Summary Table:

| Safety Feature | Purpose | Benefit |

|---|---|---|

| Automatic Door Switch | Cuts power when door opens | Prevents burns from heat exposure |

| Thermal Insulation | Contains internal heat | Keeps outer shell safe to touch |

| Over-Temperature Protection | Shuts down if overheating | Avoids equipment failure and fires |

| Electrical Circuit Breakers | Protects from power issues | Reduces risk of electric shock and fires |

Ensure your lab's safety with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today for reliable, tailored solutions that protect your operators and enhance efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis