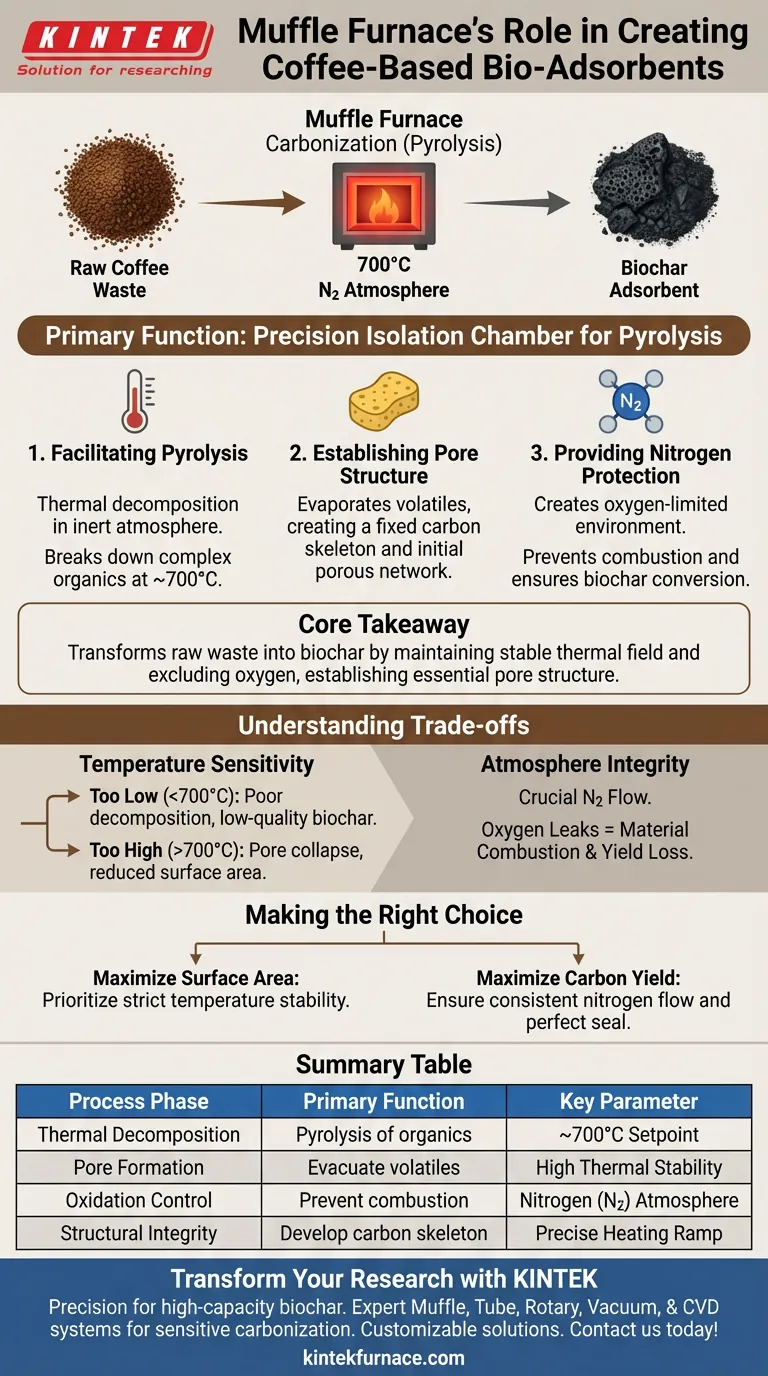

The primary function of a muffle furnace during the carbonization of coffee-based bio-adsorbents is to provide a strictly controlled, high-temperature environment to facilitate pyrolysis. By heating coffee waste to approximately 700 °C under nitrogen protection, the furnace decomposes organic substances and drives off volatile components without burning the material to ash.

Core Takeaway The muffle furnace acts as a precision isolation chamber that transforms raw coffee waste into biochar. By maintaining a stable thermal field and excluding oxygen, it establishes the initial pore structure that serves as the essential physical foundation for subsequent activation stages.

The Mechanics of Carbonization

To understand why a muffle furnace is indispensable for this process, you must look beyond simple heating. The furnace performs three critical operations simultaneously to ensure the coffee waste becomes a viable adsorbent.

Facilitating Pyrolysis

The muffle furnace is not used to burn the coffee waste; it is used to thermally decompose it. This process, known as pyrolysis, occurs when the material is subjected to high heat in an inert atmosphere.

According to standard protocols for coffee waste, the furnace must reach temperatures around 700 °C. At this specific thermal point, complex organic structures begin to break down chemically.

Establishing the Pore Structure

The effectiveness of a bio-adsorbent is defined by its surface area and porosity. As the muffle furnace heats the biomass, it forces volatile components (liquids and gases) to evaporate and exit the material.

This evacuation leaves behind empty spaces, creating a fixed carbon skeleton. This initial porous network provides the physical baseline required for any further chemical or physical activation.

Providing Nitrogen Protection

For successful carbonization, oxygen is the enemy. If coffee waste is heated to 700 °C in the presence of standard air, it will simply combust and turn into useless ash.

The muffle furnace setup allows for nitrogen protection, creating an oxygen-limited or oxygen-free environment. This ensures the biomass converts into carbon-rich biochar rather than oxidizing completely.

Understanding the Trade-offs

While the muffle furnace is the standard tool for this process, precise operation is required to avoid compromising the material.

Temperature Sensitivity

The specific temperature of 700 °C is a calculated target, not a random setting. If the temperature is too low, the volatile components may not fully decompose, resulting in low-quality biochar with poor adsorption capabilities.

Conversely, excessive temperatures can cause the porous structure to collapse or sinter. This reduces the specific surface area, rendering the final product less effective at trapping contaminants.

Atmosphere Integrity

The "muffle" design isolates the sample from direct heating elements, but it relies on an external gas supply for the inert atmosphere. Any fluctuation in nitrogen flow or leaks in the chamber can introduce oxygen.

Even minor oxidation during this phase drastically reduces the yield of fixed carbon. It essentially "eats away" the skeleton you are trying to build.

Making the Right Choice for Your Goal

When configuring your muffle furnace for coffee-based bio-adsorbents, consider your specific objectives.

- If your primary focus is maximizing surface area: Prioritize strict temperature stability at 700 °C to drive off all volatiles without collapsing the newly formed pores.

- If your primary focus is maximizing carbon yield: Ensure your nitrogen flow is consistent and the furnace seal is perfect to prevent material loss through oxidation.

The muffle furnace is not just a heater; it is the architect of your material's internal structure.

Summary Table:

| Process Phase | Primary Function | Key Parameter |

|---|---|---|

| Thermal Decomposition | Pyrolysis of organic matter | ~700 °C Setpoint |

| Pore Formation | Evacuation of volatile components | High Thermal Stability |

| Oxidation Control | Prevention of material combustion | Nitrogen (N2) Atmosphere |

| Structural Integrity | Development of carbon skeleton | Precise Heating Ramp |

Transform Your Bio-Adsorbent Research with KINTEK

Precision is the difference between high-capacity biochar and useless ash. KINTEK provides industry-leading muffle and tube furnace systems specifically designed for nitrogen-protected pyrolysis and sensitive carbonization processes.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or industrial needs. Whether you are maximizing surface area or optimizing carbon yield, our equipment ensures the stable thermal field your research demands.

Ready to elevate your material science? Contact our experts today to find the perfect high-temp solution for your lab.

Visual Guide

References

- A Coffee-Based Bioadsorbent for CO2 Capture from Flue Gas Using VSA: TG-Vacuum Tests. DOI: 10.3390/en18153965

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why Use a Muffle Furnace for TiO2 Sol-Gel? Achieve Precise Phase Control and Purity

- What are the limitations of crucible furnaces? Understand Key Trade-offs for Your Lab

- Why is a precision-controlled muffle furnace necessary for RuO2/g-C3N4 heat treatment? Ensure Perfect Catalysts

- What safety features should be considered when selecting a muffle furnace? Ensure Lab Safety with Advanced Protection Systems

- What materials are used in the construction of muffle furnaces to ensure durability? Discover the Key Components for Long-Lasting Performance

- How does furnace precision temperature control affect sintered ceramic scaffolds? Optimize Strength and Bioactivity

- How does a laboratory muffle furnace facilitate the activation of ZMQ-1 zeolite? Unlock 28-Ring Pore Channels

- What are the differences between standard and high-temperature muffle furnaces? Choose the Right Furnace for Your Lab Needs