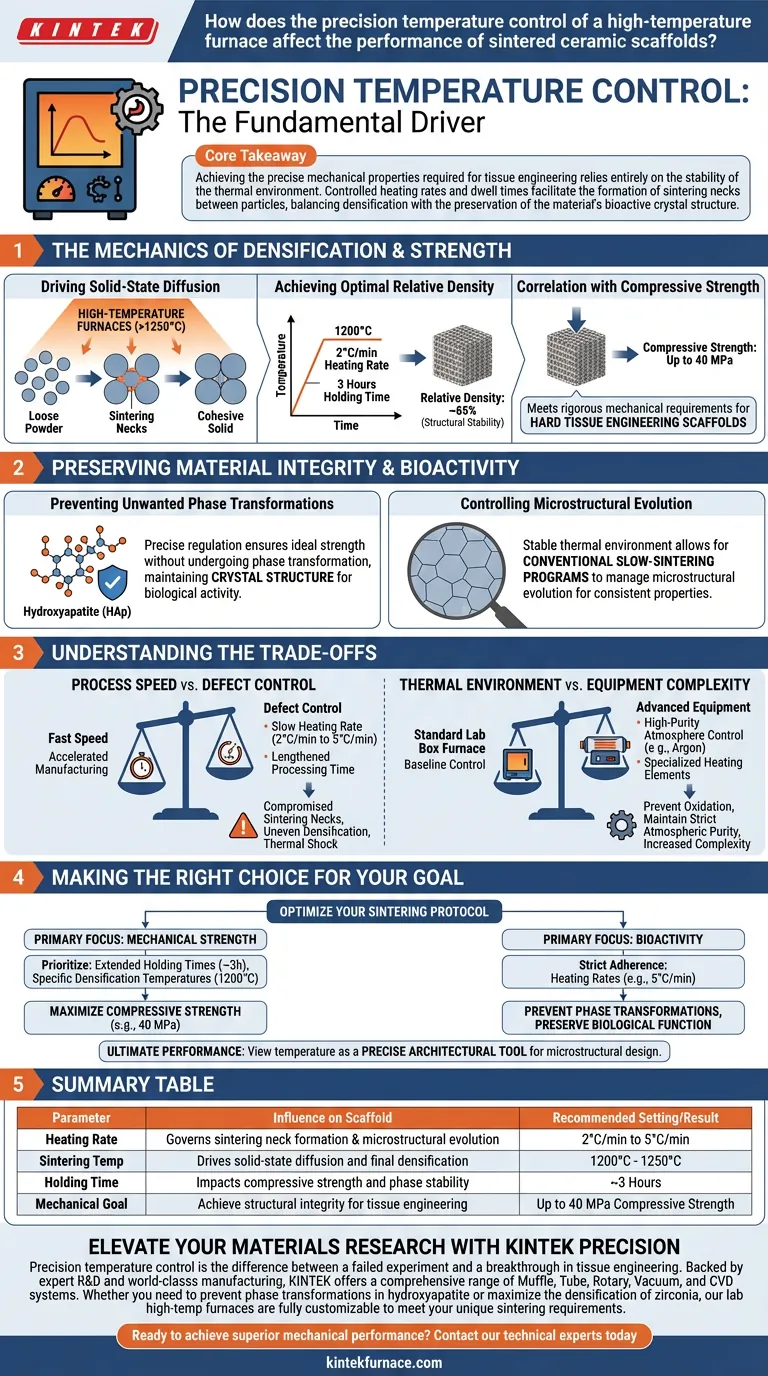

Precision temperature control is the fundamental driver of structural integrity and mechanical performance in sintered ceramic scaffolds. It strictly regulates the heating rate and holding time—for example, 2°C per minute held for 3 hours—to govern solid-state diffusion, which directly determines the material's final densification, compressive strength, and phase stability.

Core Takeaway Achieving the precise mechanical properties required for tissue engineering relies entirely on the stability of the thermal environment. Controlled heating rates and dwell times facilitate the formation of sintering necks between particles, balancing densification with the preservation of the material’s bioactive crystal structure.

The Mechanics of Densification and Strength

Driving Solid-State Diffusion

To create a functional scaffold, individual ceramic particles must fuse together without melting completely. High-temperature furnaces utilize temperatures often exceeding 1250°C to facilitate solid-phase diffusion. This process forms sintering necks between particles, which is the physical mechanism responsible for turning loose powder into a cohesive solid.

Achieving Optimal Relative Density

The specific combination of temperature and time dictates how dense the ceramic becomes. According to primary data on beta-Ca2SiO4 ceramics, sintering at 1200°C with a controlled heating rate of 2°C/min and a holding time of 3 hours results in a relative density of approximately 65%. This level of densification is critical for structural stability.

Correlation with Compressive Strength

Control over density directly translates to mechanical performance. Under the precise conditions mentioned above, ceramic scaffolds can achieve a compressive strength of up to 40 MPa. This threshold is significant because it meets the rigorous mechanical requirements necessary for hard tissue engineering scaffolds.

Preserving Material Integrity and Bioactivity

Preventing Unwanted Phase Transformations

Temperature control is not just about heat; it is about chemical stability. For materials like hydroxyapatite (HAp), precise regulation ensures the material reaches ideal strength without undergoing phase transformation. Maintaining the specific crystal structure is essential to preserve the biological activity of the scaffold.

Controlling Microstructural Evolution

The rate at which temperature increases is as important as the final temperature. Using a stable thermal environment allows for the execution of conventional slow-sintering programs. This enables researchers to manage microstructural evolution, ensuring that the physical properties of ceramics like zirconia are consistent and predictable.

Understanding the Trade-offs

Process Speed vs. Defect Control

There is often a desire to accelerate manufacturing, but high-performance ceramics demand patience. A slow heating rate (e.g., 2°C/min to 5°C/min) lengthens the total processing time significantly. However, rushing this process compromises the formation of sintering necks and can lead to uneven densification or thermal shock.

Thermal Environment vs. Equipment Complexity

Achieving high precision often requires advanced equipment capabilities, such as high-purity atmosphere control (e.g., argon) or specialized heating elements. While standard laboratory box furnaces provide a baseline for control, advanced applications may require tube furnaces to prevent oxidation or maintain strict atmospheric purity, adding distinct layers of complexity to the operation.

Making the Right Choice for Your Goal

To optimize your sintering protocol, you must align your temperature control strategy with your specific material requirements.

- If your primary focus is Mechanical Strength: Prioritize extended holding times (e.g., 3 hours) and specific densification temperatures (e.g., 1200°C) to maximize compressive strength, targeting benchmarks like 40 MPa.

- If your primary focus is Bioactivity: Strict adherence to heating rates (e.g., 5°C/min) is required to prevent phase transformations that could degrade the biological function of materials like hydroxyapatite.

Ultimate performance is achieved when you view temperature not as a simple variable, but as a precise architectural tool for microstructural design.

Summary Table:

| Parameter | Influence on Scaffold | Recommended Setting/Result |

|---|---|---|

| Heating Rate | Governs sintering neck formation & microstructural evolution | 2°C/min to 5°C/min |

| Sintering Temp | Drives solid-state diffusion and final densification | 1200°C - 1250°C |

| Holding Time | Impacts compressive strength and phase stability | ~3 Hours |

| Mechanical Goal | Achieve structural integrity for tissue engineering | Up to 40 MPa Compressive Strength |

Elevate Your Materials Research with KINTEK Precision

Precision temperature control is the difference between a failed experiment and a breakthrough in tissue engineering. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to prevent phase transformations in hydroxyapatite or maximize the densification of zirconia, our lab high-temp furnaces are fully customizable to meet your unique sintering requirements.

Ready to achieve superior mechanical performance? Contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Joelle El Hayek, Chrystelle Salameh. 3D printed bioactive calcium silicate ceramics as antibacterial scaffolds for hard tissue engineering. DOI: 10.1039/d3ma01088k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does heat transfer occur in a box furnace? Master Efficient Thermal Processing

- What temperature range can a box furnace operate in? Find the Perfect Fit for Your Lab's Needs

- What are the key applications of a muffle furnace? Essential for Pure Heat Treatment and Analysis

- What temperature ranges are available for box furnaces? Find the Perfect Fit for Your Thermal Processes

- How does a muffle furnace differ from a pusher furnace? Choose the Right Furnace for Your Lab

- How does an industrial electric box furnace maintain sample alignment? Ensure Precision in High-Throughput Calcination

- What is the function of Muffle Furnaces in raw material analysis? Optimize Energy Systems with Precise Qualification

- Why is a laboratory box resistance furnace essential for simulating long-term high-temperature oxidation exposure?