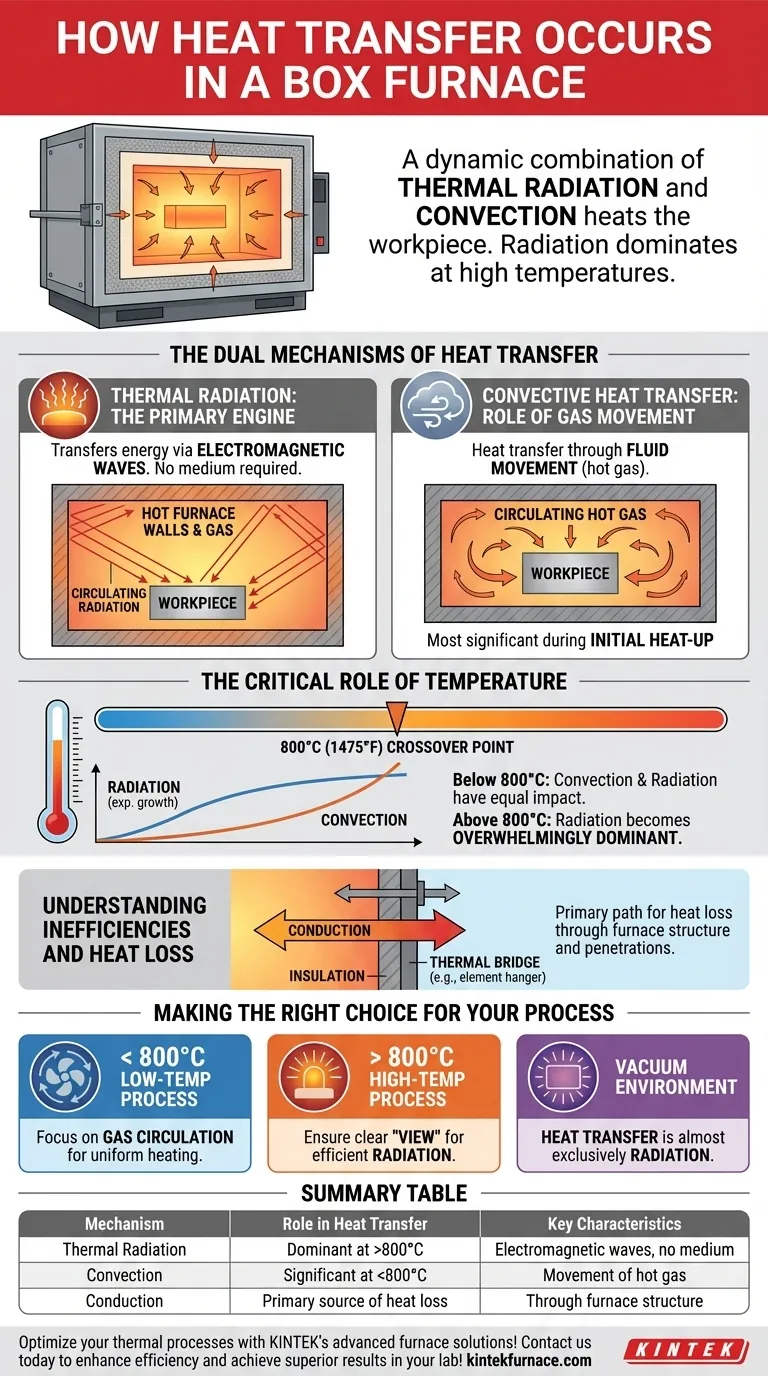

In a standard box furnace, heat is transferred to the workpiece through a dynamic combination of thermal radiation and convection. The primary heat source—whether electric elements or gas combustion—heats the internal atmosphere and the furnace walls, which in turn transfer that energy to the material being processed. At the high temperatures typical of furnace operations, radiation is the dominant mechanism.

The core principle to understand is that while both convection and radiation are always at play, their significance shifts dramatically with temperature. As a furnace heats up, radiative heat transfer rapidly overtakes convective transfer to become the primary method for heating the material.

The Dual Mechanisms of Heat Transfer

A box furnace does not heat material through a single method. Instead, it relies on two distinct but complementary physical processes working in tandem.

Thermal Radiation: The Primary Engine

Thermal radiation is the transfer of energy via electromagnetic waves. It does not require a medium, which is why you can feel the heat from a fire even from a distance.

In a furnace, radiation occurs from two main sources: the hot furnace gas (if present) and the hot interior walls (the refractory lining). These surfaces radiate heat in all directions, striking the workpiece, other walls, and the furnace roof.

The Concept of Circulating Radiation

This process is not a simple one-way transfer. When radiation strikes the surface of the workpiece or an opposing wall, some energy is absorbed, and some is reflected.

This reflected energy then travels until it strikes another surface, where it can be absorbed or reflected again. This creates a "circulating radiation" effect, ensuring that heat is distributed throughout the entire chamber, not just in the direct line of sight of the heating elements.

Convective Heat Transfer: The Role of Gas Movement

Convection is heat transfer through the movement of a fluid, in this case, the hot gas or atmosphere inside the furnace.

As the gas is heated, it circulates within the chamber, carrying thermal energy with it. When this hot gas comes into contact with the cooler surface of the workpiece, it transfers heat directly. This is most significant during the initial heat-up phase.

The Critical Role of Temperature

The balance between radiation and convection is not static; it is entirely dependent on the furnace's operating temperature.

The Crossover Point

At lower temperatures, convection and radiation can have a nearly equal impact on heat transfer. The movement of the hot gas is a very effective way to bring the part up to an initial temperature.

However, the power of radiative heat transfer increases with the fourth power of temperature (the Stefan-Boltzmann law). This means its effect grows exponentially as the furnace gets hotter.

When Radiation Dominates

Sources indicate a crossover point around 800°C (approx. 1475°F). Above this temperature, the contribution from convective heat transfer becomes significantly less important, and radiant heat transfer becomes overwhelmingly dominant.

For high-temperature processes like hardening, annealing, or sintering, you can assume that nearly all the heat transfer is being driven by radiation from the walls, roof, and heating elements.

Understanding Inefficiencies and Heat Loss

An ideal furnace would transfer 100% of its generated heat to the workpiece. In reality, energy is always lost to the surrounding environment.

Heat Loss via Conduction

The primary path for heat loss is conduction through the furnace's structure. Heat slowly moves through the insulation material itself and more quickly along any penetrations.

These penetrations include structural components like element hangers, hearth posts, and openings for thermocouples or gas nozzles. They act as thermal bridges, conducting heat out of the chamber and into the furnace's frame and the ambient air.

The Challenge of Non-Uniform Heating

A deep understanding of these heat transfer modes is critical for ensuring the workpiece is heated uniformly. Over-reliance on a single mechanism or poor furnace design can lead to hot and cold spots, resulting in inconsistent material properties, warping, or other process failures.

Making the Right Choice for Your Process

Understanding how heat moves in your furnace is the key to optimizing your process for efficiency and quality.

- If your primary focus is low-temperature processes (below 800°C): Pay close attention to gas circulation, as convection plays a major role in achieving uniform heating.

- If your primary focus is high-temperature processes (above 800°C): Your main concern is radiation. Ensure the workpiece has a clear "view" of the hot walls and elements for efficient and even heat absorption.

- If you are working in a vacuum: Convection is impossible. Heat transfer will occur almost exclusively through radiation, with some minor conduction through contact points with the hearth.

Mastering these principles allows you to move from simply operating a furnace to truly controlling a thermal process.

Summary Table:

| Mechanism | Role in Heat Transfer | Key Characteristics |

|---|---|---|

| Thermal Radiation | Dominant at high temperatures (>800°C) | Transfers energy via electromagnetic waves, no medium required |

| Convection | Significant at low temperatures (<800°C) | Involves movement of hot gas to transfer heat |

| Conduction | Primary source of heat loss | Occurs through furnace structure and penetrations |

Optimize your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to enhance efficiency and achieve superior results in your lab!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity