Muffle Furnaces serve as critical gatekeepers in the energy sector, functioning as the primary tool for the physical and chemical qualification of raw materials like coal. Through controlled high-temperature calcination and drying, these devices quantify essential properties—specifically ash content, volatile matter, and moisture—to determine if a material is suitable for efficient energy conversion.

By isolating samples from external contaminants during high-temperature testing, Muffle Furnaces provide the data necessary to ensure raw material uniformity. This preliminary analysis is the foundation for efficient downstream processing and the creation of stable fuel slurries.

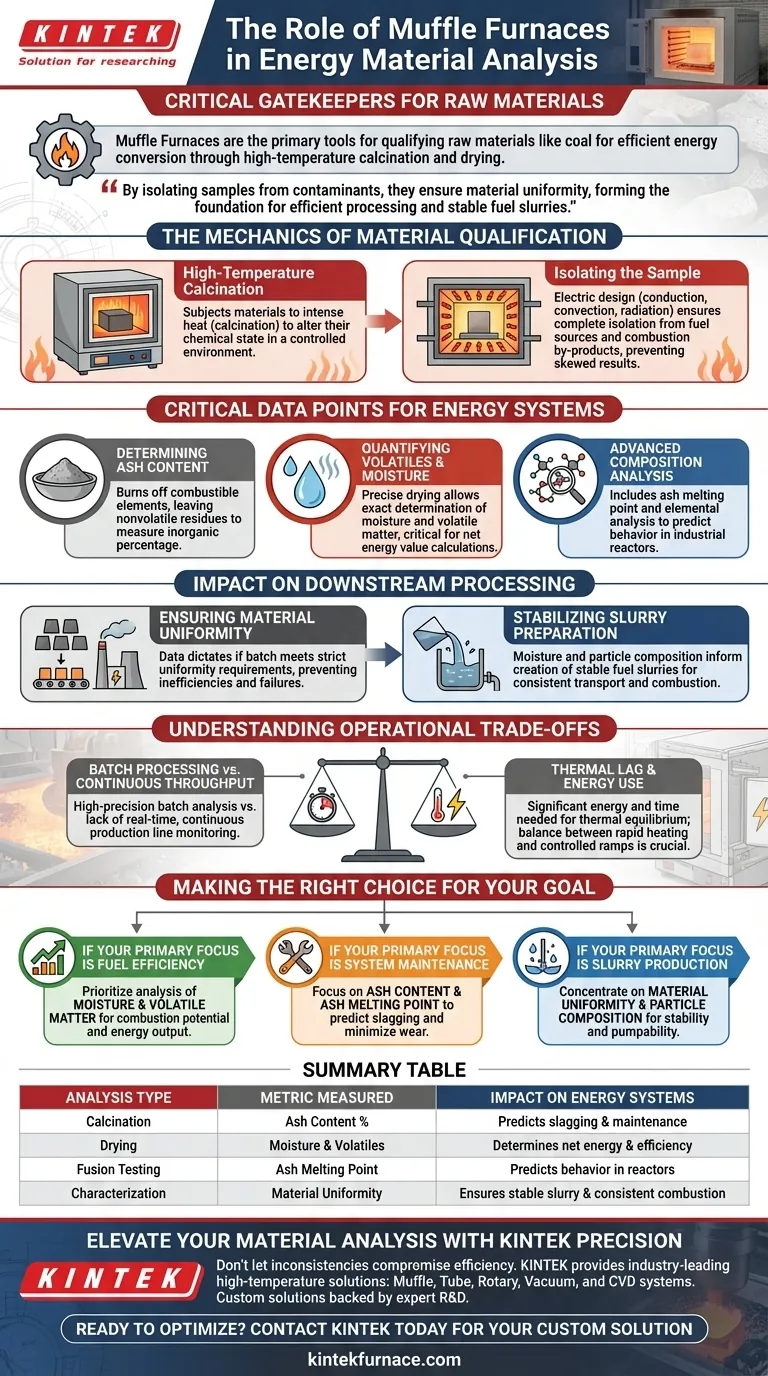

The Mechanics of Material Qualification

High-Temperature Calcination

The core function of a Muffle Furnace is to subject raw materials to intense heat to alter their chemical state. This process, known as calcination, involves heating the solid material to high temperatures in a controlled environment.

Isolating the Sample

Modern electric Muffle Furnaces utilize conduction, convection, or blackbody radiation to achieve these temperatures. Crucially, this design ensures the material is completely isolated from fuel sources and combustion by-products, such as gas or fly ash, ensuring the analytical results are not skewed by external contaminants.

Critical Data Points for Energy Systems

Determining Ash Content

One of the primary metrics gathered is the material's ash content. By burning off combustible elements, the furnace leaves behind nonvolatile residues, allowing analysts to measure the percentage of inorganic material that remains after combustion.

Quantifying Volatiles and Moisture

The furnace is also capable of precise drying operations. This allows for the exact determination of moisture levels and volatile matter, which are critical variables in calculating the net energy value of the raw fuel.

Advanced Composition Analysis

Beyond basic composition, these furnaces are utilized for more complex characterizations. This includes ash melting point analysis and elemental analysis, which help predict how the fuel will behave inside an industrial boiler or reactor.

Impact on Downstream Processing

Ensuring Material Uniformity

The data provided by the Muffle Furnace dictates whether a batch of raw material meets the strict uniformity requirements of an energy plant. Inconsistent raw materials can lead to inefficiencies or mechanical failures in large-scale systems.

Stabilizing Slurry Preparation

For systems relying on liquid fuel mixtures, this analysis is vital. The measurements of moisture and particle composition directly inform the creation of stable slurries, ensuring the fuel mixture remains consistent during transport and combustion.

Understanding the Operational Trade-offs

Batch Processing vs. Continuous Throughput

Muffle Furnaces are designed for high-precision laboratory analysis, which inherently operates on a batch basis. While this provides exact data for specific samples, it does not offer real-time, continuous monitoring of a production line.

Thermal Lag and Energy Use

Achieving the extreme temperatures required for ash fusion or calcination requires significant energy and time to reach thermal equilibrium. Operators must balance the need for rapid heating with the necessity of controlled temperature ramps to prevent thermal shock to the ceramic muffle or the sample itself.

Making the Right Choice for Your Goal

To maximize the utility of a Muffle Furnace in your analysis workflow, consider your specific data requirements.

- If your primary focus is Fuel Efficiency: Prioritize analysis of moisture and volatile matter, as these directly correlate to the combustion potential and energy output of the raw material.

- If your primary focus is System Maintenance: Focus on ash content and ash melting point analysis to predict slagging potential and minimize wear on industrial boilers.

- If your primary focus is Slurry Production: Concentrate on material uniformity and particle composition, as these factors determine the stability and pumpability of the final fuel mixture.

Accurate preliminary analysis is the single most effective way to prevent costly inefficiencies in large-scale energy production.

Summary Table:

| Analysis Type | Metric Measured | Impact on Energy Systems |

|---|---|---|

| Calcination | Ash Content % | Predicts slagging and boiler maintenance needs |

| Drying | Moisture & Volatiles | Determines net energy value and fuel efficiency |

| Fusion Testing | Ash Melting Point | Predicts material behavior in industrial reactors |

| Characterization | Material Uniformity | Ensures stable fuel slurry and consistent combustion |

Elevate Your Material Analysis with KINTEK Precision

Don't let raw material inconsistencies compromise your energy production efficiency. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to deliver the precise data your laboratory demands. Backed by expert R&D and world-class manufacturing, our furnaces are fully customizable to meet your unique thermal processing requirements.

Ready to optimize your fuel qualification process?

Contact KINTEK Today to Find Your Custom Solution

Visual Guide

References

- Shiwei Yu, Mingjie Feng. Workflow Design and Operational Analysis of a Coal‐Based Multi‐Energy Combined Supply System for Electricity, Heating, Cooling, and Gas. DOI: 10.1002/ese3.70137

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-precision muffle furnace required for BCZT xerogel pre-calcination? Ensure Pure Phase and Reactivity

- What materials can crucible furnaces melt? A Guide to Metals, Glass & Advanced Materials

- What are the industrial uses of a muffle furnace? Enhance Precision and Purity in High-Temp Applications

- How are muffle furnaces used in the glass industry? Precision Heating for Quality Control and Tempering

- What are the main industries that use muffle furnaces? Essential for Clean Heat in Labs and Manufacturing

- What is the main advantage of a muffle furnace? Ensure Purity and Longevity in High-Temp Processes

- What is a Muffle furnace and what are its main characteristics? Discover High-Purity Heating Solutions

- Why are muffle furnaces important for determining moisture, ash, and volatile content in pharmaceutical materials? Ensure Purity and Compliance