At its core, a crucible furnace is a highly versatile tool capable of melting a wide range of materials. Primarily, these furnaces are used for melting metals and alloys, but their capabilities extend to materials like glass and certain ceramics, depending on the furnace's design and maximum temperature.

The specific materials a crucible furnace can melt are not determined by the furnace alone, but by the critical relationship between the furnace's maximum temperature and the melting point of the material used for the crucible itself.

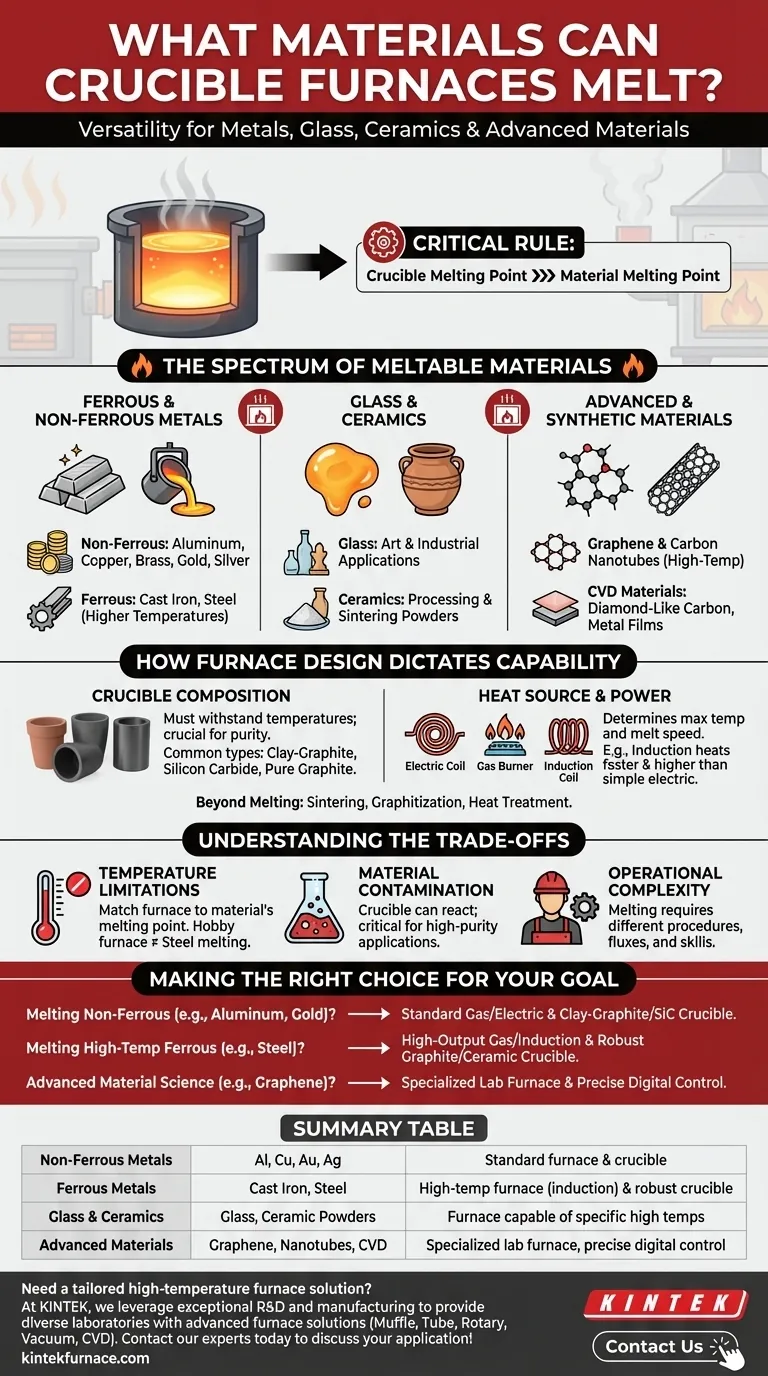

The Spectrum of Meltable Materials

Crucible furnaces are defined by their adaptability, serving industries from small-scale jewelry making to large-scale industrial manufacturing and advanced materials research.

Ferrous and Non-Ferrous Metals

This is the most common application for crucible furnaces. They are widely used to melt non-ferrous metals like aluminum, copper, brass, bronze, zinc, gold, and silver.

With sufficient power and the correct crucible type, they are also capable of melting ferrous metals such as cast iron and steel, which have significantly higher melting points.

Glass and Ceramics

Select crucible furnaces can reach the high temperatures required to melt glass for art or industrial applications. They can also be used in the processing and sintering of some ceramic materials, turning powders into solid forms.

Advanced and Synthetic Materials

Specialized graphite crucible furnaces are critical in modern material science. They are used in the production of graphene and carbon nanotubes, which require extremely high, stable temperatures.

Other advanced furnaces, such as Chemical Vapor Deposition (CVD) units, utilize a similar principle to synthesize materials like diamond-like carbon, metal films, and advanced composites.

How Furnace Design Dictates Capability

The term "crucible furnace" is broad. The actual performance and material compatibility depend entirely on its core components and heating method.

The Critical Role of the Crucible

The crucible is the container that holds the material to be melted. Its composition is the single most important factor.

A fundamental rule is that the crucible must have a significantly higher melting point than the material it holds. Common crucible materials include clay-graphite, silicon carbide, and pure graphite.

The Importance of the Heat Source

The furnace's heating system (e.g., electric resistance, gas, or induction) determines the maximum achievable temperature and the speed of the melt. An induction furnace, for example, heats much faster and can reach higher temperatures than a simple electric resistance furnace.

Beyond Melting: Other High-Temperature Processes

The precise temperature control of these furnaces makes them useful for more than just melting. They are often employed for sintering (fusing powders together with heat), graphitization (converting carbon into graphite), and general heat treatment of parts.

Understanding the Trade-offs

While versatile, crucible furnaces have limitations that are critical to understand for successful operation.

Temperature Limitations

Not every furnace can melt every material. A hobby-grade furnace designed for aluminum (melting point ~660°C / 1220°F) will be completely unable to melt steel (melting point ~1510°C / 2750°F).

The Risk of Material Contamination

The crucible material can sometimes react with the molten charge, introducing impurities. This is a major concern in applications requiring high-purity metals or alloys, demanding careful selection of the crucible.

Operational Complexity

Melting different materials requires different procedures. Factors like temperature ramps, the use of flux to remove impurities, and pouring techniques vary significantly between metals like aluminum and iron, requiring operator skill and knowledge.

Making the Right Choice for Your Goal

To select the right setup, you must match the furnace and crucible directly to the material you intend to process.

- If your primary focus is melting non-ferrous metals like aluminum, brass, or gold: A standard gas or electric resistance furnace with a clay-graphite or silicon carbide crucible is the industry standard.

- If your primary focus is melting high-temperature metals like steel or iron: You will need a high-output gas furnace or an induction furnace paired with a robust graphite or specialized ceramic crucible.

- If your primary focus is advanced material science or synthesis: A specialized laboratory furnace (like a graphite or CVD furnace) with precision digital temperature control is essential.

Ultimately, successful melting is about choosing a system where both the furnace and its crucible are engineered for the specific temperatures and chemical properties of your target material.

Summary Table:

| Material Category | Common Examples | Key Considerations |

|---|---|---|

| Non-Ferrous Metals | Aluminum, Copper, Brass, Gold, Silver | Standard furnace & crucible (e.g., clay-graphite) |

| Ferrous Metals | Cast Iron, Steel | High-temp furnace (e.g., induction) & robust crucible (e.g., graphite) |

| Glass & Ceramics | Glass, Ceramic Powders | Furnace capable of reaching specific high temperatures |

| Advanced Materials | Graphene, Carbon Nanotubes, CVD Films | Specialized lab furnace with precise digital control |

Need a high-temperature furnace solution tailored to your specific material?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced furnace solutions. Whether you're melting common non-ferrous metals, processing high-temperature steels, or synthesizing advanced materials like graphene, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact our experts today to discuss how we can engineer the perfect furnace system for your application.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide