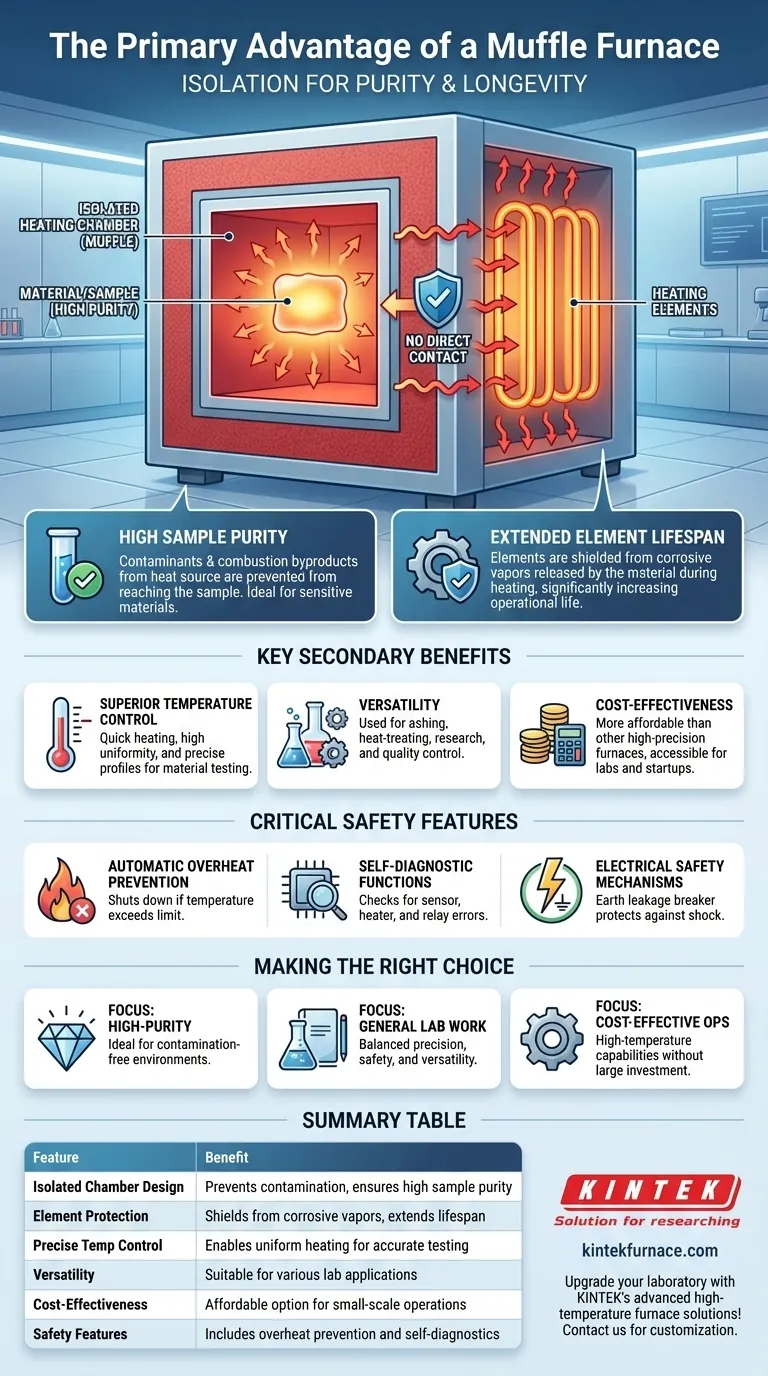

The primary advantage of a muffle furnace is its unique design that isolates the material being heated from the heating elements. This separation prevents direct contact with combustion byproducts or contaminants from the heat source, ensuring high sample purity while also protecting the heating elements from corrosive vapors and significantly extending their operational lifespan.

A muffle furnace's core value lies in its isolated chamber design. This creates a clean, controlled environment that guarantees uncontaminated results for sensitive materials and prolongs the furnace's own durability, a combination that is critical for precise laboratory and small-scale work.

How a Muffle Furnace Achieves Its Advantage

The key to the muffle furnace's performance is the "muffle" itself—an insulated, separate inner chamber that holds the workpiece. The heating elements heat the outside of this chamber, and the heat radiates inward.

The Core Principle: A Contamination-Free Chamber

The furnace's unique feature is its isolated heating chamber. This design ensures that the material being processed never comes into direct contact with the heating elements or any byproducts of combustion.

This isolation is essential for applications where even trace amounts of contamination can ruin an experiment or a material sample.

Protecting the Heating Elements

When materials are heated to high temperatures, they often release vapors and gases. These emissions can be corrosive and will degrade heating elements over time if they are in direct contact.

By placing the heating elements outside the processing chamber, the muffle furnace shields them from these damaging effects. This simple design choice dramatically increases the lifespan and reliability of the equipment.

Key Secondary Benefits

While purity and longevity are the main advantages, muffle furnaces offer other significant benefits that make them a staple in laboratories and workshops.

Superior Temperature Control and Efficiency

Modern muffle furnaces are engineered for high performance. They are capable of reaching high temperatures quickly and offer superior temperature uniformity and control.

This precision is critical for material testing, heat treating, and other processes that rely on specific temperature profiles.

Versatility for Laboratory Applications

The controlled, clean environment makes the muffle furnace exceptionally versatile. It is used for everything from ashing samples and heat-treating metals to materials research and quality control testing.

Accessibility and Cost-Effectiveness

Compared to other types of high-temperature furnaces with similar precision, muffle furnaces are often more affordable. This makes them an accessible option for educational institutions, startups, and labs with budget constraints.

Understanding Critical Safety Features

Safe operation is non-negotiable when working with extreme temperatures. A reliable muffle furnace is defined as much by its safety systems as its heating performance.

Automatic Overheat Prevention

A fundamental safety feature is the ability to automatically shut down if the temperature exceeds a set limit. This prevents damage to the furnace, the sample, and the surrounding workspace.

Self-Diagnostic Functions

Advanced models include self-diagnostic systems that continuously check for errors. These functions monitor for sensor failures, heater disconnections, and short circuits in the solid-state relays (SSR) or triacs that control power.

Electrical Safety Mechanisms

An earth leakage breaker is a crucial component that protects the operator from electric shock in the event of an electrical fault, immediately cutting power to the unit.

Making the Right Choice for Your Application

Selecting the right furnace requires aligning its strengths with your specific goals.

- If your primary focus is high-purity processing or analysis: The muffle furnace is the ideal choice because its isolated chamber guarantees a contamination-free environment.

- If your primary focus is general laboratory work: The furnace's balance of precise temperature control, safety, and versatility makes it a highly effective and reliable tool for diverse applications.

- If your primary focus is cost-effective, small-scale operations: A muffle furnace provides access to high-temperature processing capabilities without the significant investment required for larger, more specialized industrial furnaces.

Ultimately, the muffle furnace excels by providing a pure, controlled, and reliable heating environment for applications where precision matters most.

Summary Table:

| Feature | Benefit |

|---|---|

| Isolated Chamber Design | Prevents contamination from heating elements, ensuring high sample purity |

| Element Protection | Shields heating elements from corrosive vapors, extending lifespan |

| Precise Temperature Control | Enables uniform heating for accurate material testing and heat treatment |

| Versatility | Suitable for ashing, heat-treating, and research in various lab settings |

| Cost-Effectiveness | Affordable option for educational, startup, and small-scale operations |

| Safety Features | Includes overheat prevention, self-diagnostics, and electrical safety mechanisms |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for contamination-free results and extended equipment life. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis