In the glass industry, muffle furnaces are primarily used for material analysis, small-batch melting for recycling, and heat treatment processes like tempering and shaping. Their key advantage is providing a highly controlled, high-temperature environment that is isolated from direct heating elements, which is critical for achieving specific material properties in glass.

A muffle furnace's value in the glass industry isn't for mass production, but for precise, contamination-free heating. This makes it indispensable for quality control, specialty forming, and strengthening processes where material integrity is paramount.

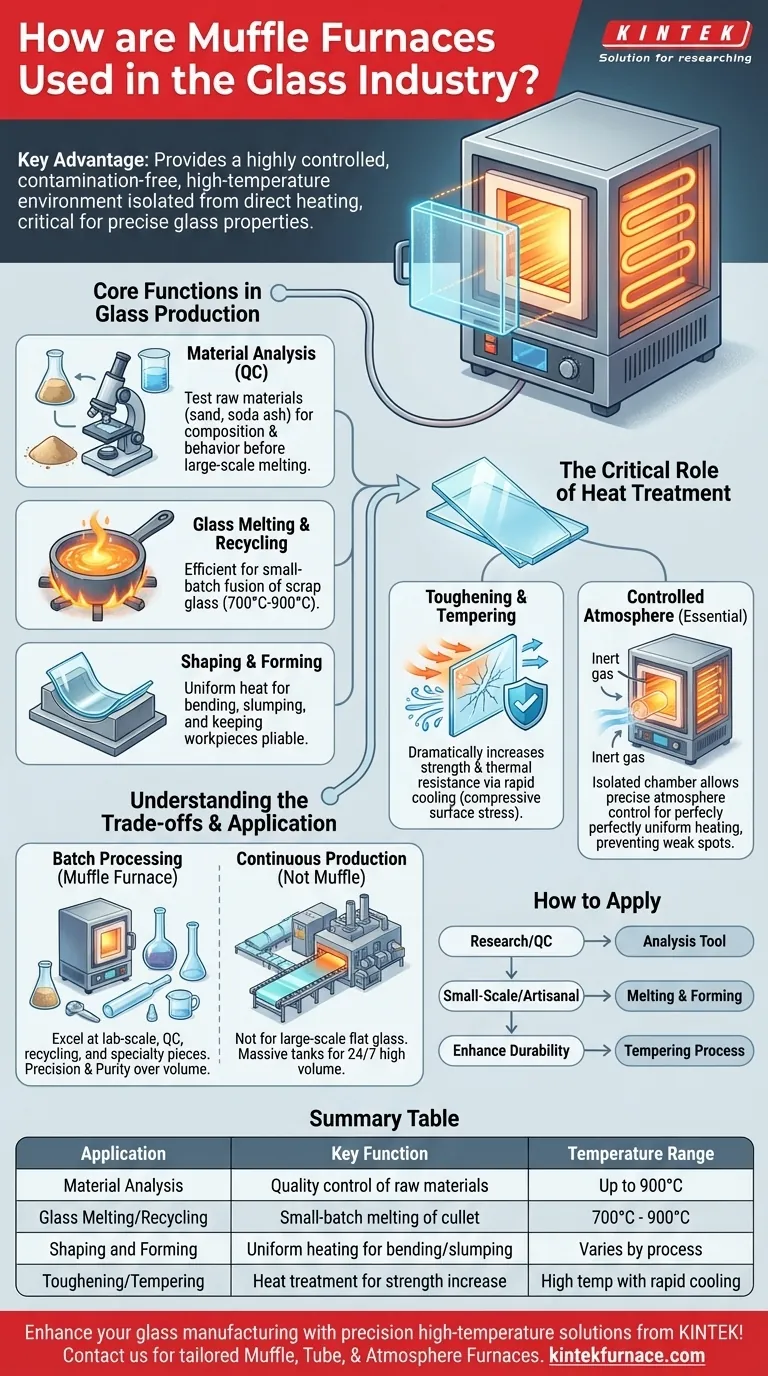

Core Functions in Glass Production

A muffle furnace serves several distinct, high-value roles in the lifecycle of glass manufacturing. These tasks leverage the furnace's ability to deliver uniform heat without introducing impurities from combustion byproducts.

Material Analysis for Quality Control

Before large-scale melting, raw materials must be tested. A muffle furnace is the ideal lab instrument for analyzing the properties of sand, soda ash, and limestone.

By heating small samples under controlled conditions, technicians can verify chemical composition and predict how the materials will behave during production, ensuring consistent quality.

Glass Melting and Recycling

Muffle furnaces are used to melt glass, particularly for recycling processes. Scrap glass, or "cullet," can be melted down in batches to be reformed into new products.

While not used for the vast quantities of a float glass plant, their efficiency in reaching temperatures of 700°C to 900°C makes them perfect for smaller-scale fusion.

Shaping and Forming

Certain glass products require heating to become pliable for shaping. Muffle furnaces provide the uniform heat needed for processes like glass bending or slumping.

They can also be used to support blow molding operations by keeping glass workpieces at a consistent, workable temperature between stages.

The Critical Role of Heat Treatment

Beyond melting and forming, the most crucial application is altering the physical properties of the finished glass through precise thermal processes.

Toughening and Tempering

Tempering is a heat treatment process that dramatically increases the strength and thermal resistance of glass. It involves heating the glass to a high temperature and then cooling it rapidly.

This creates compressive stress on the surface and tensile stress in the core, making the glass four to five times stronger than standard annealed glass.

Why a Controlled Atmosphere is Essential

This is where the "muffle" design is critical. The chamber is isolated from the heating elements, allowing for a controlled atmosphere that prevents oxidation on the glass surface.

Atmosphere control, often using inert gases, ensures perfectly uniform heating and cooling. This uniformity is what prevents weak spots and results in high-quality tempered glass for applications like automotive windows and architectural glazing.

Understanding the Trade-offs

While versatile, it's important to recognize the specific role of a muffle furnace. They are not the primary tool for all glass manufacturing.

Batch vs. Continuous Production

Muffle furnaces excel at batch processing. They are ideal for lab-scale experiments, quality control tests, recycling, and creating specialty or custom glass pieces.

They are generally not used for the large-scale, continuous production of flat glass (float glass), which relies on massive, specialized melting tanks that operate 24/7.

Scale and Application

The decision to use a muffle furnace is driven by scale and objective. For tasks requiring precision, purity, and controlled thermal cycling on a smaller scale, it is the superior choice. For sheer volume, other furnace types are more economical.

How to Apply This to Your Process

Your specific goal will determine how you leverage a muffle furnace.

- If your primary focus is research or quality control: The muffle furnace is your essential tool for analyzing raw material properties and testing sample behavior.

- If your primary focus is small-scale or artisanal production: It provides the necessary heat for melting, recycling cullet, and forming unique shapes.

- If your primary focus is enhancing product durability: A muffle or atmosphere furnace is non-negotiable for controlled tempering and strengthening processes.

Ultimately, the muffle furnace empowers glass manufacturers with precision, allowing for the creation of materials that meet exacting standards of quality and strength.

Summary Table:

| Application | Key Function | Temperature Range |

|---|---|---|

| Material Analysis | Quality control of raw materials | Up to 900°C |

| Glass Melting/Recycling | Small-batch melting of cullet | 700°C - 900°C |

| Shaping and Forming | Uniform heating for bending/slumping | Varies by process |

| Toughening/Tempering | Heat treatment for strength increase | High temp with rapid cooling |

Enhance your glass manufacturing with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for quality control, recycling, or tempering processes. Contact us today to discuss how our tailored furnace solutions can boost your efficiency and product quality!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals