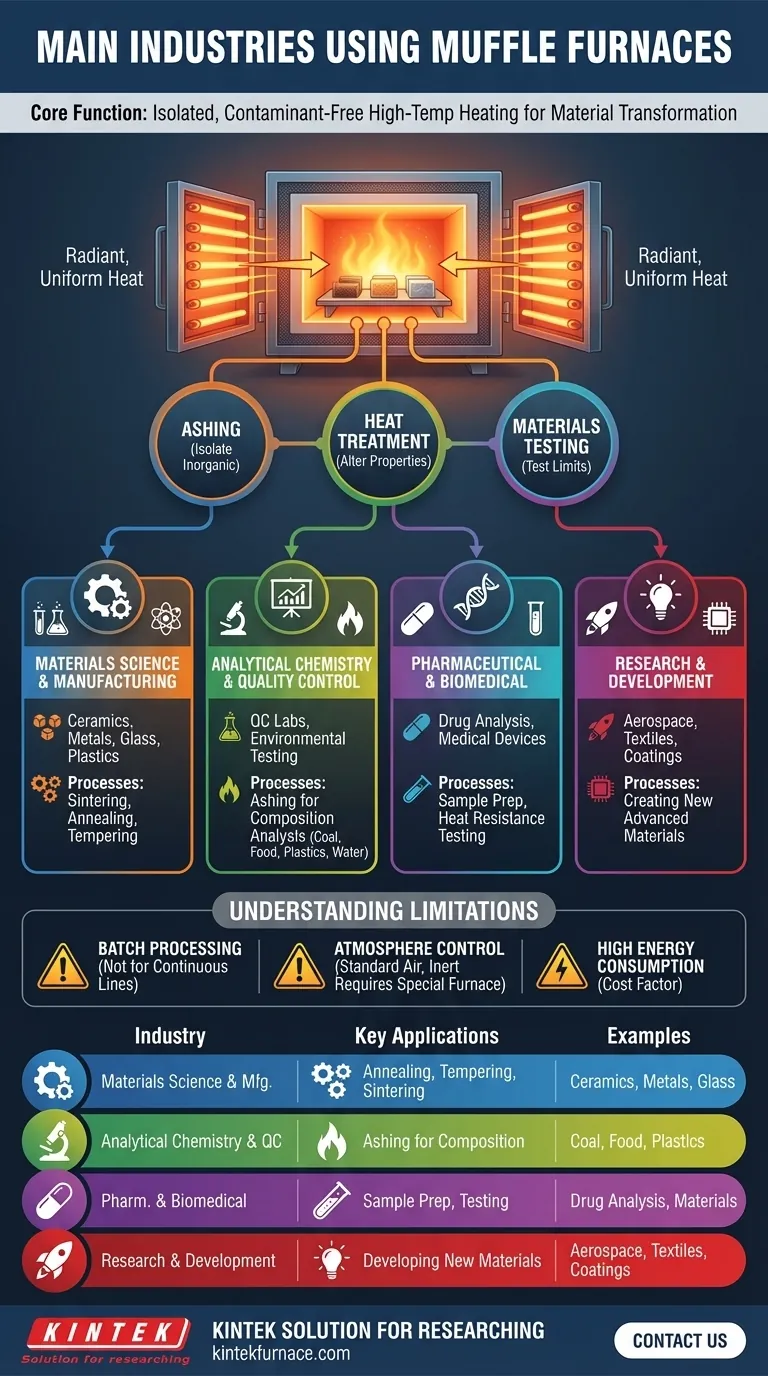

At its core, a muffle furnace is an essential tool for high-temperature material transformation, making it indispensable across a surprisingly diverse set of industries. Its primary users are found in materials science (ceramics, metals, glass), analytical chemistry, pharmaceuticals, and quality control laboratories where controlled, contaminant-free heating is critical.

The widespread use of muffle furnaces stems from a single requirement: the need to heat a material to an extreme temperature without it being contaminated by combustion byproducts or direct contact with the heating elements. This principle of clean thermal processing is fundamental for determining a material's composition, creating new materials, or testing their limits.

The Core Function: An Isolated Thermal Environment

A muffle furnace's value isn't just about reaching high temperatures; it's about how it gets there. Understanding this function clarifies its broad industrial appeal.

What Defines a Muffle Furnace?

The key is in the name. A "muffle" is a sealed, insulated chamber, typically made of ceramic, that separates the material being heated from the furnace's heating elements.

This design ensures that heat is transferred radiantly and uniformly to the sample. It prevents any contamination that could alter the results of a sensitive test or the properties of a new material.

The Primary Applications

Across all industries, the use of a muffle furnace boils down to a few key processes: ashing, heat treatment, and materials testing.

Key Applications Across Major Industries

Different industries leverage these core functions for specific goals, from quality control to cutting-edge research.

Materials Science and Manufacturing

This is perhaps the most common domain. Industries working with ceramics, glass, metals, and plastics rely on muffle furnaces for foundational processes.

Heat treatment techniques like annealing (softening metals), tempering (toughening them), and sintering (fusing ceramic or metal powders into a solid mass) all require the precise, uniform heat that a muffle furnace provides.

Analytical Chemistry and Quality Control

In analytical labs, the furnace is a workhorse for sample preparation. The most common application is ashing.

By heating a sample (like coal, food, or plastic) to a very high temperature, all organic components burn away, leaving only the inorganic ash. Analyzing this ash is a critical quality control step to determine the material's composition. This is also used in environmental testing, such as water quality analysis.

Pharmaceutical and Biomedical Sectors

In pharmaceuticals, muffle furnaces are used to prepare samples for drug analysis, ensuring that the sample is free from contaminants before it undergoes further testing.

They are also used in the biomedical field to test the heat resistance of materials used in medical devices or to prepare samples for compositional analysis.

Research and Development

In both academic and industrial labs, muffle furnaces are vital for creating and testing new materials. This includes developing advanced composites for aerospace, new fibers for the textile industry, or high-performance pigments for the paint and coatings industry.

Understanding the Limitations

While versatile, a muffle furnace is not a universal solution for all heating needs. Its design comes with specific trade-offs.

Best for Batch Processing

Muffle furnaces are designed for processing individual samples or small batches. They are not suited for continuous, high-volume production lines, which require different types of industrial ovens and kilns.

Atmosphere Control is a Key Consideration

A standard muffle furnace operates with a normal air atmosphere. If a process requires an inert atmosphere (like nitrogen or argon) to prevent oxidation, a more specialized and expensive furnace is required.

High Energy Consumption

Reaching temperatures of 1000°C or higher is an energy-intensive process. The operational cost, particularly for frequent or prolonged use, is a significant factor for any facility.

Making the Right Choice for Your Goal

Your industry's specific objective determines how you will use a muffle furnace.

- If your primary focus is determining material composition: You will use the furnace for ashing to isolate inorganic components, a key process in quality control for coal, food, plastics, and cement.

- If your primary focus is creating or altering materials: You will use heat treatment processes like sintering, annealing, or tempering, which are fundamental in ceramics, metallurgy, and glass manufacturing.

- If your primary focus is preparing samples for analysis: You are likely in a pharmaceutical, environmental, or chemical lab, using the furnace to create a clean, stable sample for more advanced analytical techniques.

Ultimately, understanding the core principle of controlled, isolated heat reveals why the muffle furnace is such a versatile and enduring tool across the scientific and industrial landscape.

Summary Table:

| Industry | Key Applications |

|---|---|

| Materials Science & Manufacturing | Annealing, tempering, sintering of ceramics, metals, glass |

| Analytical Chemistry & Quality Control | Ashing for composition analysis in coal, food, plastics |

| Pharmaceutical & Biomedical | Sample preparation for drug analysis, material testing |

| Research & Development | Developing new materials for aerospace, textiles, coatings |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you're in materials science, pharmaceuticals, or quality control, our furnaces deliver contaminant-free heating for ashing, heat treatment, and materials testing—ensuring accurate results and enhanced efficiency.

Contact us today to discuss how we can tailor a solution for your specific needs and boost your lab's performance!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?