At its core, a muffle furnace is used for three primary purposes: high-temperature heat treatment of materials, quantitative chemical analysis through ashing, and the creation of new materials like ceramics. Its defining feature is a sealed inner chamber—the "muffle"—that isolates the sample from heating element contaminants, enabling precise and pure thermal processing in fields ranging from metallurgy and materials science to analytical chemistry and environmental testing.

The fundamental value of a muffle furnace is not just its ability to reach high temperatures, but its capacity to do so within a controlled, contaminant-free environment. This thermal purity is the critical factor that makes it an indispensable tool for analysis, treatment, and creation.

The Core Principle: Isolated High-Temperature Heating

What Makes a "Muffle" Furnace Unique?

A muffle furnace is a type of oven that can reach very high temperatures. Its key component is the muffle, an insulated chamber made of a high-temperature ceramic or alloy.

This chamber isolates the material being heated from the actual heating elements and any combustion byproducts. This separation is critical for preventing contamination and ensuring the thermal process affects only the sample itself.

Why a Contaminant-Free Environment Matters

In many high-temperature processes, direct exposure to the byproducts of fuel combustion or oxidizing heating elements can alter the chemical composition of the sample.

By placing the sample inside the muffle, you ensure that the heat is transferred cleanly, typically through radiation and convection. This allows for processes that demand high purity, such as analyzing trace elements or creating sensitive electronic components.

Key Applications in Analysis and Quality Control

This group of applications uses heat to break down a sample to measure its components.

Ashing for Compositional Analysis

Ashing is the most common analytical use for a muffle furnace. The process involves heating a sample at a high temperature to burn off all its organic and volatile substances.

What remains is the ash, an inorganic residue. By weighing the sample before and after ashing, analysts can accurately determine the percentage of non-combustible material. This is vital for quality control in the food, pharmaceutical, and environmental industries.

Gravimetric and Volatile Matter Testing

Muffle furnaces are used to perform gravimetric analysis, where mass is used to determine the quantity of an analyte. This includes determining the moisture content or the amount of volatile matter that is released from a sample at specific temperatures.

These tests are fundamental in materials science, geology, and environmental analysis for characterizing materials like coal, cement, and soil.

Pharmaceutical and Biomedical QC

In pharmaceuticals, muffle furnaces are used to test drug stability under thermal stress and to determine the inorganic impurity content of raw materials or final products.

In biomedical labs, they are used for the clean incineration of biological samples for trace metal analysis or for the sterile disposal of materials.

Key Applications in Material Creation and Treatment

This group of applications uses heat to change the physical or chemical properties of a material.

Heat Treatment of Metals

Metallurgy relies heavily on muffle furnaces to alter the properties of metals and alloys. The controlled environment is perfect for processes that require precision.

Common treatments include annealing (to soften metal and improve ductility), hardening (to increase strength), and tempering (to reduce brittleness).

Sintering of Ceramics and Glass

Sintering is a process where powdered materials—like ceramics or metals—are heated to fuse them into a solid, dense object without melting them completely.

Muffle furnaces provide the stable, high temperatures needed to create advanced ceramic components, dental crowns, and specialty glass products.

Material Durability and Stress Testing

In research and development, muffle furnaces are used to test how materials perform under extreme thermal stress. This helps engineers understand a material's durability, degradation point, and overall reliability for high-temperature applications.

Understanding the Trade-offs and Limitations

While powerful, muffle furnaces are not without constraints. Understanding these is key to using them effectively.

Temperature Ramping and Uniformity

Muffle furnaces have significant thermal mass, meaning they take a considerable amount of time to heat up and cool down. This slow ramp rate can impact laboratory throughput.

Furthermore, while they provide stable temperatures, achieving perfect temperature uniformity across the entire chamber can be a challenge, potentially creating slight variations in samples placed in different locations.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. If a process requires an inert or reactive gas environment (such as nitrogen, argon, or hydrogen), a specialized and more expensive furnace with gas-purging capabilities is necessary.

Safety and Energy Consumption

Operating at temperatures often exceeding 1000°C (1832°F), these furnaces pose significant burn risks and require proper ventilation for fumes produced during ashing. They are also energy-intensive devices, contributing to high operational costs.

Making the Right Choice for Your Goal

To select or properly utilize a muffle furnace, align its capabilities with your primary objective.

- If your primary focus is analytical chemistry (ashing, QC): Prioritize a furnace with exceptionally precise temperature control, good ventilation, and a chamber material that will not react with your samples.

- If your primary focus is materials science (heat treating, sintering): Look for a furnace with a high maximum temperature, programmable heating/cooling cycles, and consider whether you need atmosphere control for your specific materials.

- If your primary focus is general research or material testing: A versatile, general-purpose model with a wide temperature range and robust, user-friendly controls will provide the most flexibility.

Understanding that a muffle furnace's true function is to provide pure, isolated heat empowers you to apply it effectively across any scientific or industrial discipline.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Analysis & Quality Control | Ashing, gravimetric testing, pharmaceutical QC |

| Material Creation & Treatment | Heat treatment of metals, sintering, durability testing |

| General Research | Material testing, thermal stress analysis |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you're in analytical chemistry, materials science, or general research, our furnaces deliver contaminant-free heating for accurate results. Contact us today to discuss how we can enhance your thermal processes and drive innovation in your projects!

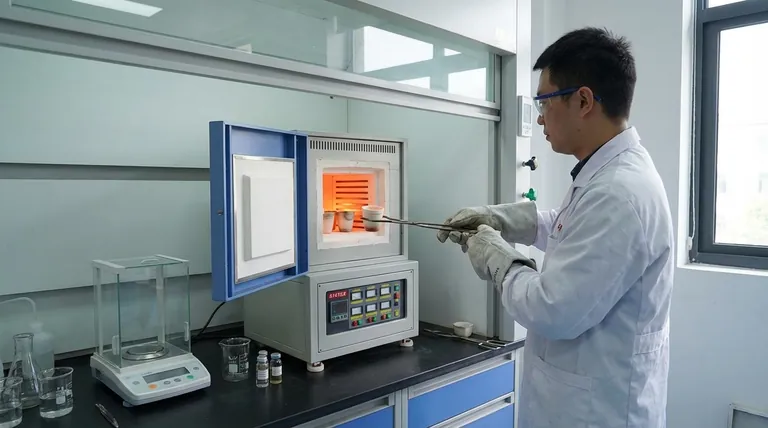

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals