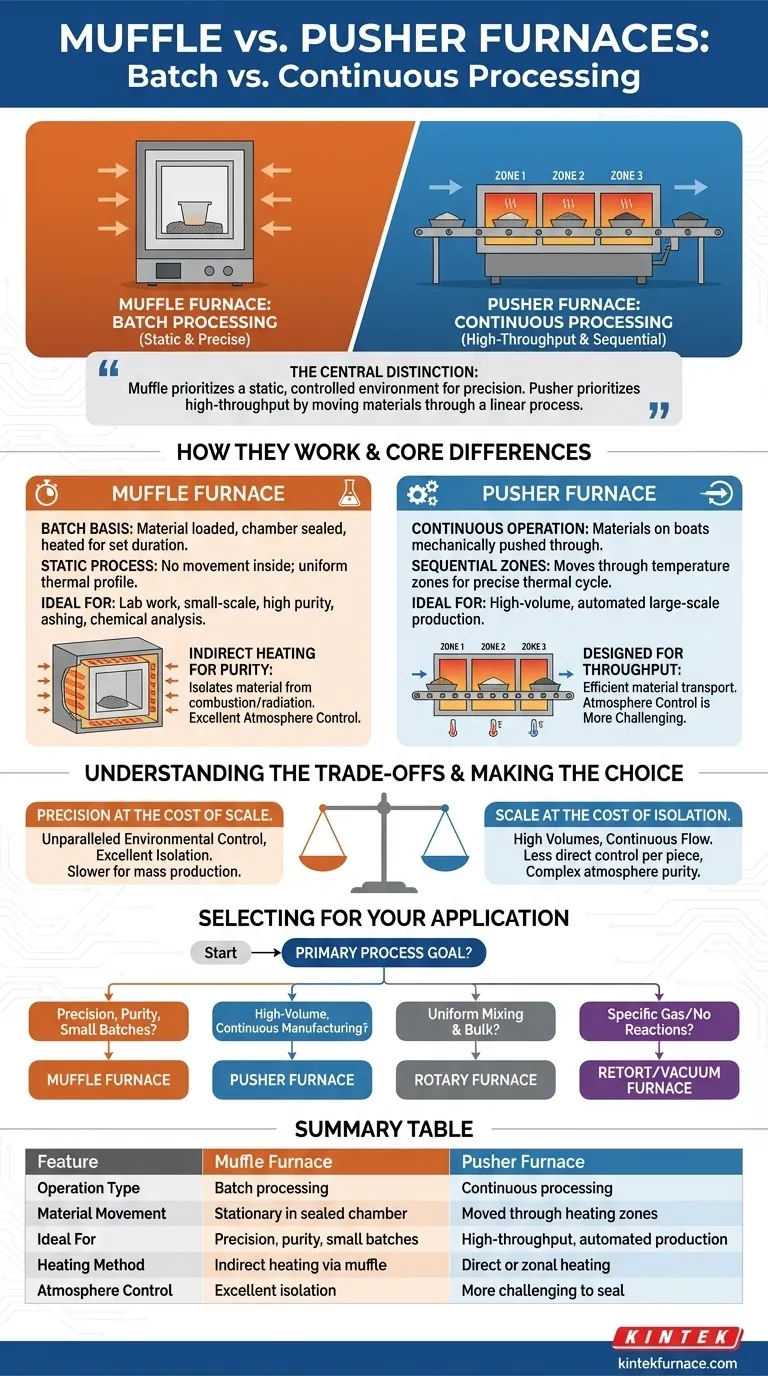

At its core, the difference between a muffle furnace and a pusher furnace comes down to their mode of operation. A muffle furnace is a batch-processing tool that heats stationary materials inside a sealed, isolated chamber, while a pusher furnace is a continuous-processing tool that moves materials sequentially through different heating and cooling zones.

The central distinction is simple: a muffle furnace prioritizes a highly controlled, static environment for precision and purity, making it ideal for batch work. A pusher furnace prioritizes high-throughput, continuous production by moving materials through a linear process.

The Core Operational Difference: Batch vs. Continuous

The most fundamental distinction lies in how material is handled during the thermal process. This single difference dictates the ideal applications for each furnace type.

How a Muffle Furnace Works

A muffle furnace operates on a batch basis. Materials are placed inside a sealed chamber (the "muffle"), the door is closed, and the entire chamber is brought up to the desired temperature for a set duration.

The process is static; the material does not move once inside. This design is ideal for laboratory work, small-scale production, or processes where every part of the sample must experience the exact same thermal profile simultaneously.

How a Pusher Furnace Works

A pusher furnace is designed for continuous operation. Materials, often placed on trays or "boats," are loaded at the entrance and mechanically pushed through a long horizontal chamber.

This chamber is divided into multiple zones, each set at a specific temperature. As the material is pushed from one zone to the next, it undergoes a precise, pre-programmed thermal cycle, emerging fully processed at the exit.

The Defining Feature: Heating Method and Atmosphere

Beyond the operational mode, the method of heating and degree of atmospheric control are critical differentiators that stem from their core designs.

The Muffle: Indirect Heating for Purity

The key feature of a muffle furnace is the muffle itself—an inner chamber that isolates the material from the heating elements. This indirect heating prevents any contamination from combustion byproducts or direct radiation from the elements.

This isolation is crucial for applications like ashing, chemical analysis, or treating sensitive materials where purity and uniform heat distribution are paramount.

The Pusher Furnace: Designed for Throughput

While pusher furnaces can maintain a controlled atmosphere, their primary design focus is on efficient material transport. The continuous entry and exit of materials make achieving a perfectly sealed environment more challenging than in a closed-door muffle furnace.

The goal is to create a consistent thermal profile along the length of the furnace, ensuring each part moving through receives the same treatment, rather than creating a perfectly uniform static environment.

Understanding the Trade-offs

Neither furnace is universally superior; the choice depends entirely on balancing the need for precision against the demand for production volume.

Muffle Furnace: Precision at the Cost of Scale

The strength of a muffle furnace is its unparalleled environmental control. It offers precise temperature uniformity and excellent isolation, but this comes at the cost of throughput. Since it is a batch process, it is inherently slower for mass production.

Pusher Furnace: Scale at the Cost of Isolation

The clear advantage of a pusher furnace is its ability to handle high volumes of material in a continuous, automated flow. However, the control over any single piece is less direct than in a batch furnace, and achieving the same level of atmospheric purity is more complex.

Making the Right Choice for Your Application

Selecting the correct furnace requires a clear understanding of your primary process goal, whether it is speed, purity, or another specific outcome.

- If your primary focus is high-volume, continuous manufacturing: A pusher furnace is engineered specifically for consistent, automated, large-scale production.

- If your primary focus is precision, contamination-free processing in a lab or for small batches: A muffle furnace provides the necessary isolation and static temperature control.

- If your primary focus is uniform mixing and heat treatment of bulk materials: A rotary furnace, which tumbles the material, may be a more suitable choice than either.

- If your primary focus is processing in a specific gas or eliminating all atmospheric reactions: A retort or vacuum furnace offers superior environmental control for highly sensitive materials.

Ultimately, your decision rests on balancing the need for continuous throughput against the requirement for environmental precision.

Summary Table:

| Feature | Muffle Furnace | Pusher Furnace |

|---|---|---|

| Operation Type | Batch processing | Continuous processing |

| Material Movement | Stationary in sealed chamber | Moved through heating zones |

| Ideal For | Precision, purity, small batches | High-throughput, automated production |

| Heating Method | Indirect heating via muffle | Direct or zonal heating |

| Atmosphere Control | Excellent isolation | More challenging to seal |

Need expert guidance on selecting the right furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation