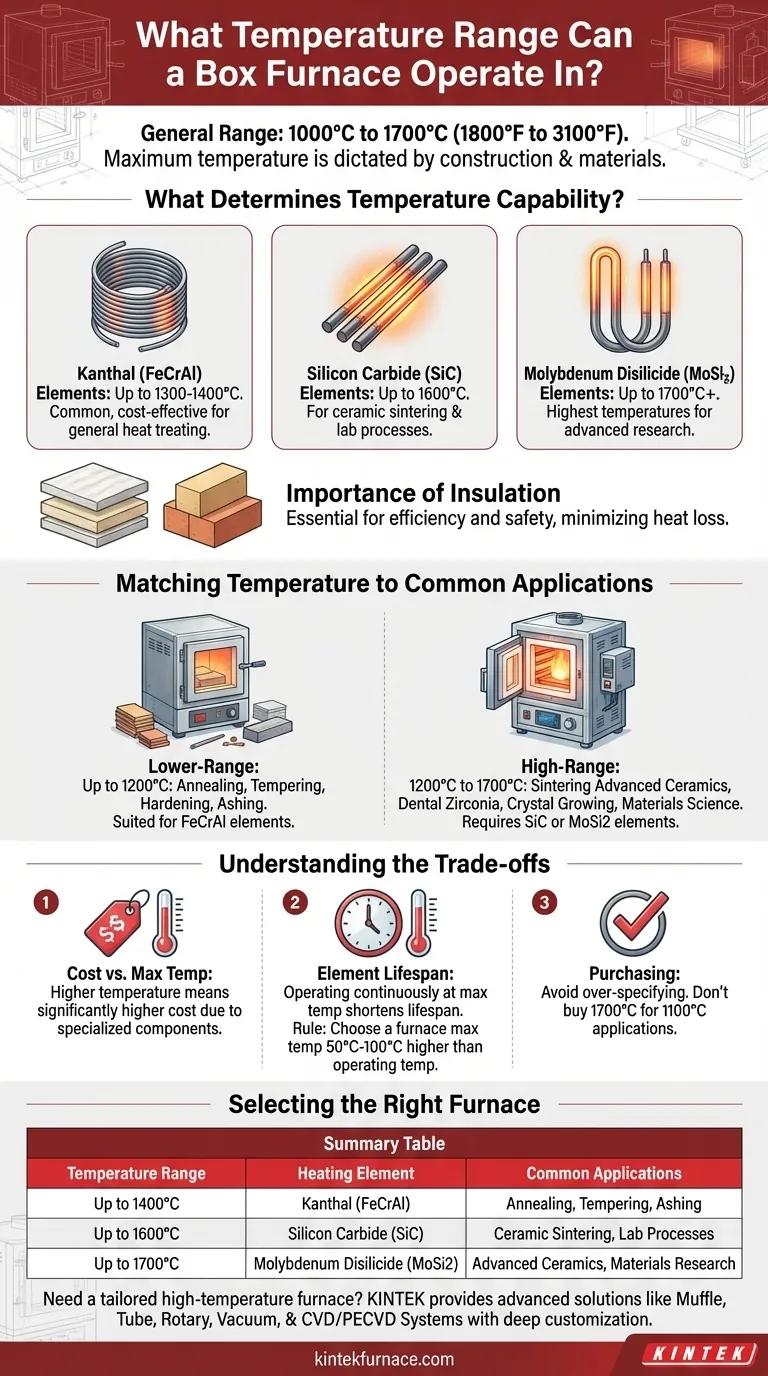

In short, a standard industrial or laboratory box furnace operates within a temperature range of approximately 1000°C to 1700°C (1800°F to 3100°F). While this is the general capability, the specific maximum temperature of any given furnace is not a universal constant; it is dictated entirely by its construction and materials.

The critical takeaway is that a box furnace's maximum temperature is determined by its core components, primarily the type of heating element and the quality of its insulation. Understanding this relationship is the key to selecting a furnace that is both effective for your process and cost-efficient to operate.

What Determines a Box Furnace's Temperature Capability?

A box furnace is not a single entity but a system of components working together. The maximum achievable temperature is a direct result of the physical limits of these materials.

The Critical Role of Heating Elements

The heating elements are the heart of the furnace, responsible for converting electrical energy into heat. Different materials have vastly different temperature ceilings.

-

Kanthal (FeCrAl) Elements: These are the most common and cost-effective elements, typically used for applications up to 1300°C-1400°C. They are robust and reliable for general-purpose heat treating.

-

Silicon Carbide (SiC) Elements: For higher temperatures, SiC elements are a frequent choice. They can operate reliably up to 1600°C, making them suitable for some ceramic sintering and lab processes.

-

Molybdenum Disilicide (MoSi2) Elements: When you need to reach the highest temperatures, MoSi2 elements are the standard. They enable furnaces to reach and sustain temperatures of 1700°C and even slightly beyond, but they come at a higher cost.

The Importance of Insulation

Reaching a high temperature is only half the battle; maintaining it efficiently and safely requires excellent insulation.

Materials like refractory ceramic fiber and insulating firebrick are used to line the furnace chamber. Furnaces designed for higher temperatures require more advanced, multi-layered insulation packages to minimize heat loss and protect the outer shell.

Matching Temperature to Common Applications

The required temperature for your process is the most important factor when choosing a furnace.

Lower-Range Applications (Up to 1200°C)

Processes like annealing, tempering, hardening of most steels, and ashing fall into this range. A standard furnace with FeCrAl elements is perfectly suited and highly economical for these tasks.

High-Range Applications (1200°C to 1700°C)

More demanding processes require furnaces with superior capabilities. This includes the sintering of advanced ceramics, dental zirconia, crystal growing, and specialized materials science research. These applications mandate the use of SiC or MoSi2 elements.

Understanding the Trade-offs

Selecting a furnace with a higher temperature rating involves a series of important trade-offs that impact cost and longevity.

Cost vs. Maximum Temperature

There is a direct and steep correlation between a furnace's maximum temperature and its price. The specialized heating elements (MoSi2) and advanced insulation required for 1700°C operation are significantly more expensive than standard components.

Element Lifespan and Operating Conditions

Continuously operating any furnace at its absolute maximum rated temperature will drastically shorten the life of its heating elements. It is a fundamental best practice to choose a furnace with a maximum temperature at least 50°C to 100°C higher than your normal operating temperature.

Purchasing for Your Needs

Avoid the mistake of over-specifying. Buying a 1700°C furnace for a 1100°C process leads to unnecessary capital expense and potentially higher maintenance costs without any performance benefit for your application.

Selecting the Right Furnace for Your Process

Making an informed choice requires aligning the furnace's capabilities with your specific operational goals.

- If your primary focus is general heat treating or lab work below 1200°C: A furnace with Kanthal (FeCrAl) elements provides the ideal balance of performance, cost, and durability.

- If your primary focus is ceramic work or processes requiring up to 1600°C: A furnace equipped with Silicon Carbide (SiC) elements is the necessary and appropriate choice.

- If your primary focus is advanced materials research at temperatures up to 1700°C: You must invest in a specialized furnace with Molybdenum Disilicide (MoSi2) elements, accepting the higher associated cost.

By matching the furnace's material construction to your specific temperature needs, you ensure both process success and long-term operational efficiency.

Summary Table:

| Temperature Range | Heating Element | Common Applications |

|---|---|---|

| Up to 1400°C | Kanthal (FeCrAl) | Annealing, tempering, ashing |

| Up to 1600°C | Silicon Carbide (SiC) | Ceramic sintering, lab processes |

| Up to 1700°C | Molybdenum Disilicide (MoSi2) | Advanced ceramics, materials research |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety