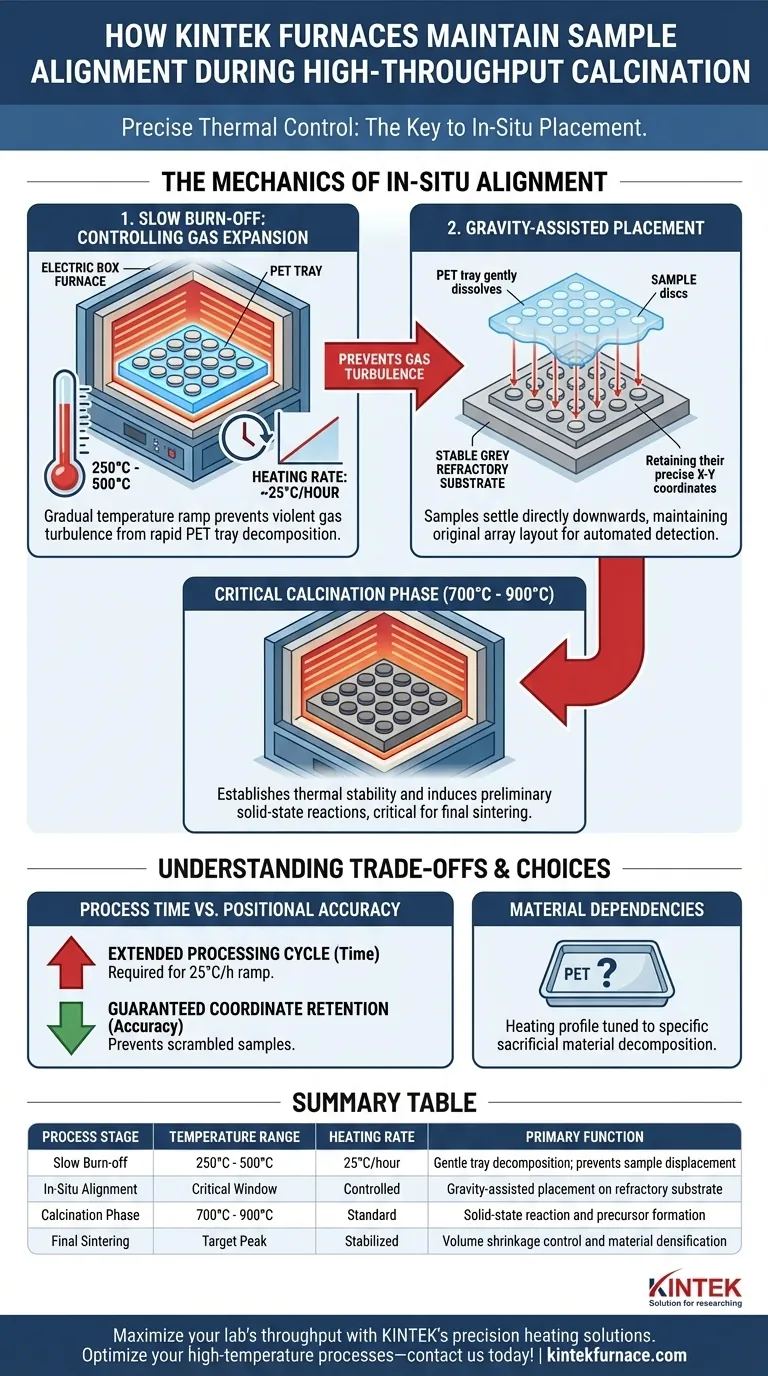

Precise thermal control is the primary mechanism for maintaining alignment. An industrial-grade electric box furnace ensures high-throughput samples remain ordered by implementing a specifically designed slow heating rate—typically 25°C per hour within the critical 250°C to 500°C window. This gradual temperature ramp ensures that sacrificial PET trays burn off gently without creating violent gas flows, allowing the sample discs to land in-situ on the refractory substrate without being displaced.

By strictly controlling the burn-off rate of sacrificial materials, the furnace prevents gas turbulence that would otherwise displace lightweight samples, preserving the precise X-Y coordinates required for automated downstream detection.

The Mechanics of In-Situ Alignment

Controlling Gas Expansion

The biggest threat to sample alignment during the early stages of heating is turbulence.

If the temperature rises too quickly, the sacrificial PET trays holding the samples will combust or decompose rapidly.

This rapid decomposition generates a sudden, high volume of gas that can physically blow lightweight sample discs out of position.

The Critical Temperature Window

To prevent this, the furnace utilizes a highly specific heating profile between 250°C and 500°C.

By limiting the heating rate to approximately 25°C per hour in this zone, the furnace forces a slow, controlled burn-off.

This ensures the gas evolves at a manageable rate, leaving the environment inside the chamber relatively static.

Gravity-Assisted Placement

As the PET tray slowly disintegrates, gravity takes over in a controlled manner.

Because the support structure disappears gradually rather than violently, the sample discs settle directly downward.

They land on the refractory substrate in their original array layout, maintaining the coordinates necessary for automated robots to locate them later.

The Role of the Calcination Phase

Establishing Thermal Stability

Once the alignment is secured and the tray is removed, the furnace moves to the true calcination temperature range, typically 700°C to 900°C.

The electric box furnace provides a stable thermal field at these temperatures to induce preliminary solid-state reactions.

Precursor Formation

During this high-temperature stage, raw oxides react to form the ferrite precursor structure.

This step is critical for minimizing volume shrinkage during the final sintering stage.

However, the success of this phase relies entirely on the samples being in the correct position, which was determined during the earlier low-temperature ramp.

Understanding the Trade-offs

Process Time vs. Positional Accuracy

The primary trade-off in this method is time.

A heating rate of 25°C per hour significantly extends the processing cycle compared to rapid-fire calcination.

However, attempting to speed up this specific ramp will almost certainly result in "scrambled" samples and a failure of the automated detection system.

Material Dependencies

This alignment strategy is heavily dependent on the sacrificial material used (in this case, PET).

The heating profile must be tuned specifically to the decomposition characteristics of the tray material.

Changing the tray material without adjusting the ramp rate could reintroduce gas turbulence or leave unwanted residue that affects sample purity.

Making the Right Choice for Your Goal

To ensure your high-throughput process succeeds, you must prioritize the heating profile based on your specific operational needs.

- If your primary focus is Automated Detection: Strictly adhere to the 25°C/h ramp rate between 250°C and 500°C to guarantee coordinate retention.

- If your primary focus is Phase Composition: Ensure the furnace can maintain a stable thermal field in the 700°C to 900°C range to facilitate proper solid-state reactions.

Success in high-throughput calcination is defined not just by reaching the target temperature, but by how carefully you navigate the journey there.

Summary Table:

| Process Stage | Temperature Range | Heating Rate | Primary Function |

|---|---|---|---|

| Slow Burn-off | 250°C - 500°C | 25°C/hour | Gentle tray decomposition; prevents sample displacement |

| In-Situ Alignment | Critical Window | Controlled | Gravity-assisted placement on refractory substrate |

| Calcination Phase | 700°C - 900°C | Standard | Solid-state reaction and precursor formation |

| Final Sintering | Target Peak | Stabilized | Volume shrinkage control and material densification |

Maximize your lab's throughput with KINTEK’s precision heating solutions. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain strict positional accuracy for automated workflows. Optimize your high-temperature processes with KINTEK—contact us today!

Visual Guide

References

- Christopher Hampson, Matthew J. Rosseinsky. A high throughput synthetic workflow for solid state synthesis of oxides. DOI: 10.1039/d3sc05688k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the design features of a muffle furnace? Key Components for Precision and Purity

- What key components are used in vacuum muffle furnaces to ensure precise gas dispersion? Discover the MFC and BPR System

- What are the environmental requirements for muffle furnace nanocrystallization of Fe-based alloys?

- What features help box furnaces maintain uniform temperatures? Key Design Elements for Precise Heat Distribution

- How does the temperature control system work in a muffle furnace? Ensure Precise Heating for Your Lab

- What are the typical applications of a muffle furnace? Achieve Precision and Purity in High-Temp Processes

- Why is the temperature control capability of a muffle furnace critical during the preparation of Ba2M0.4Bi1.6O6?

- What advantages do muffle furnaces offer for material processing? Achieve Precision and Purity in Heat Treatment