In short, a box furnace achieves uniform temperature through a combination of high-efficiency heating elements, advanced insulation, strategic structural design, and often, active air circulation. These features work in concert to distribute heat evenly and minimize loss to the surrounding environment.

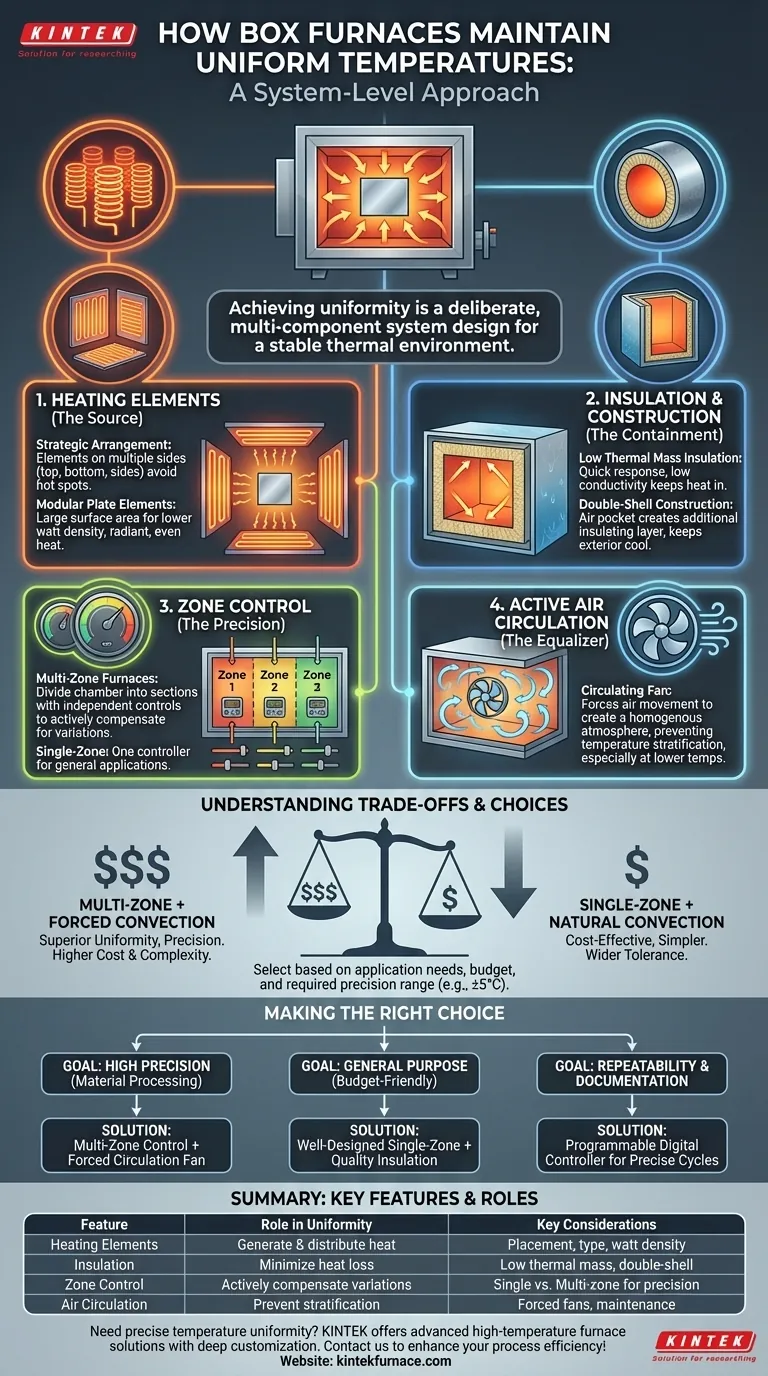

Achieving temperature uniformity is not the result of a single component, but a deliberate system-level design. The goal is to create a stable thermal environment where every part of the workpiece experiences the same temperature, which is critical for predictable process outcomes.

The Core Components of Temperature Uniformity

True uniformity is a product of how the furnace generates, contains, and distributes heat. Each component plays a specific role in managing this thermal energy.

The Role of Heating Elements

The source of the heat is the logical starting point. The type, placement, and power management of heating elements are fundamental to an even temperature distribution.

Proper arrangement of heating elements is the first step. By placing elements on multiple sides of the chamber, designers can avoid "hot spots" and ensure heat radiates toward the workload from all directions.

Modern furnaces often use modular plate heating elements. These have a large surface area, which allows them to operate at a lower watt density, promoting more even, radiant heat transfer and extending element life.

The Importance of Insulation and Construction

Containing heat is just as important as generating it. Heat loss through the furnace walls creates cold spots and wastes energy.

High-quality furnaces use low thermal mass insulation. This material heats up and cools down quickly, but more importantly, it has very low thermal conductivity, which keeps heat locked inside the chamber.

A double-shell construction is another key feature. This design allows for a pocket of air between the inner and outer furnace walls, which acts as an additional insulating layer and keeps the exterior of the furnace cool and safe.

Achieving Precision with Zone Control

For larger furnaces or applications requiring extreme precision, a single set of controls is often insufficient.

A single-zone furnace has one controller managing all heating elements. This is suitable for many general-purpose applications.

Multi-zone furnaces divide the chamber into two or more sections, each with its own thermocouple and controller. This allows the system to add more or less heat to specific areas, actively compensating for natural temperature variations and ensuring superior uniformity across the entire work chamber.

Active Uniformity with Air Circulation

While radiation and natural convection distribute heat passively, some processes require more active intervention.

Many high-performance box furnaces include a circulating fan. The fan forces air movement throughout the chamber, ensuring a homogenous atmosphere and preventing temperature stratification, especially at lower temperature ranges where radiant heat transfer is less effective.

Understanding the Trade-offs

Selecting a furnace requires balancing performance requirements with budget and complexity. The features that enhance uniformity often come with associated costs.

Single-Zone vs. Multi-Zone

A multi-zone furnace provides undeniably superior temperature uniformity. However, it is more expensive due to the additional controllers, thermocouples, and wiring. For processes with a wide tolerance, a well-designed single-zone furnace is a more cost-effective solution.

Natural Convection vs. Forced Convection

Adding a circulation fan significantly improves uniformity but introduces a mechanical component that requires maintenance and can be a point of failure. It also adds to the initial cost of the furnace. For high-temperature applications where radiation is the dominant form of heat transfer, a fan may be unnecessary.

The Meaning of Uniformity Specifications

Manufacturers typically specify uniformity as a range, such as ±5°C or ±10°C, within a defined work volume. It is critical to understand if this specification applies to an empty furnace or one under load, as the workpiece itself will impact the thermal dynamics. Always verify that the furnace's rated uniformity meets the precise needs of your process.

Making the Right Choice for Your Process

Your specific application determines which features are most critical for your success.

- If your primary focus is high-precision material processing: Prioritize a furnace with multi-zone control and a forced air circulation fan to achieve the tightest possible temperature window.

- If your primary focus is general-purpose heating on a budget: A well-designed single-zone furnace with quality insulation and strategic element placement is often sufficient.

- If your primary focus is process repeatability and documentation: Invest in a furnace with a fully programmable digital controller that can execute and record precise heating and cooling cycles.

Ultimately, understanding how these systems work together empowers you to select a furnace that will reliably meet your technical goals.

Summary Table:

| Feature | Role in Uniformity | Key Considerations |

|---|---|---|

| Heating Elements | Generate and distribute heat evenly | Placement, type (e.g., modular plates), watt density |

| Insulation | Minimizes heat loss and cold spots | Low thermal mass, double-shell construction |

| Zone Control | Actively compensates for temperature variations | Single-zone for cost, multi-zone for precision |

| Air Circulation | Prevents stratification and ensures homogeneity | Forced fans for lower temps, maintenance trade-offs |

Need a box furnace that delivers precise temperature uniformity for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your process efficiency and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits