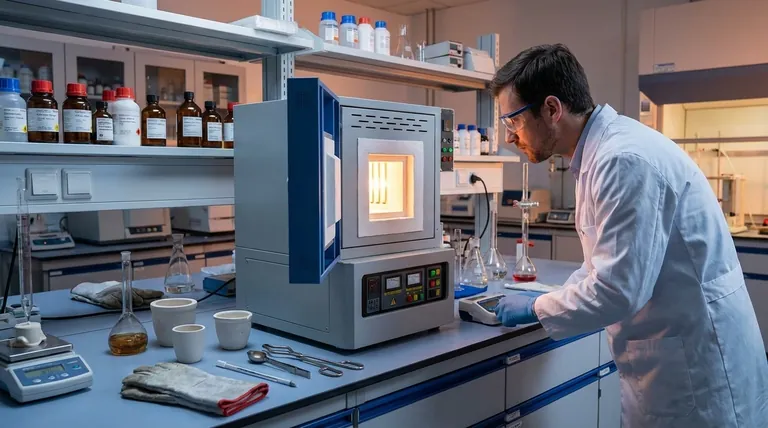

Precise temperature control in a muffle furnace is the deciding factor in the successful synthesis of Ba2M0.4Bi1.6O6. It ensures the stable thermodynamic environment required for solid-state reactions, specifically maintaining a constant sintering temperature of 950 °C for 12 hours. Without this stability, the material fails to achieve the correct double perovskite phase and risks developing undesirable amorphous structures.

Temperature uniformity within the furnace chamber is not merely an operational detail; it dictates the structural integrity of the final material. Accurate control facilitates the precise transition into specific crystal structures while suppressing defects that compromise material quality.

The Role of Thermodynamics in Phase Formation

Achieving the Double Perovskite Structure

The synthesis of Ba2M0.4Bi1.6O6 relies heavily on a consistent thermodynamic environment.

The furnace must maintain a constant temperature of 950 °C for an extended period, typically 12 hours. This sustained heat drives the chemical reactions necessary to form the high-quality double perovskite phase.

Controlling Crystal Transitions

Beyond simple phase formation, the specific crystal structure of the material is temperature-dependent.

Uniform heating allows for the precise transition between complex space groups, such as Monoclinic I2/m or Cubic Fm3m. Fluctuations in temperature can interrupt these transitions, leading to inconsistent material properties.

Microstructural Integrity and Grain Growth

Suppressing Amorphous Phases

Inconsistent heating often results in incomplete reactions.

When temperature control is accurate, it effectively suppresses the formation of amorphous phases. These are non-crystalline regions that can degrade the performance of the final material.

Promoting Proper Grain Development

The microstructure of the material is defined during the sintering process.

A uniform thermal environment promotes proper grain development. This ensures the material is dense and structurally sound, rather than porous or weakly bonded.

Operational Risks and Equipment Limitations

Preventing Component Burnout

While achieving high temperatures is necessary, how you reach them matters significantly.

The voltage applied to the furnace must be increased gradually. Rapid spikes in voltage to force a temperature increase can cause the heating element to exceed its maximum specification and burn out.

The Necessity of Supervision

Automatic control systems are reliable but not infallible.

It is crucial to supervise the furnace to detect potential failures in the automatic control system. Unchecked failures can lead to furnace wire burnout or other accidents that destroy both the equipment and the sample.

Making the Right Choice for Your Goal

To ensure the successful preparation of Ba2M0.4Bi1.6O6, prioritize the following operational strategies:

- If your primary focus is Phase Purity: Ensure your furnace creates a uniform thermal zone at exactly 950 °C to guarantee the formation of the double perovskite structure and correct space groups.

- If your primary focus is Microstructural Quality: Maintain strict temperature stability to prevent amorphous phase formation and encourage uniform grain growth.

- If your primary focus is Equipment Longevity: Increase voltage gradually and supervise the system to prevent heating element burnout due to control failures.

Mastering the thermal environment is the only way to transform raw precursors into a high-quality, crystalline double perovskite.

Summary Table:

| Synthesis Factor | Requirement | Impact on Ba2M0.4Bi1.6O6 |

|---|---|---|

| Sintering Temp | Constant 950 °C | Formation of high-quality double perovskite phase |

| Dwell Time | 12 Hours | Ensures complete solid-state reaction |

| Thermal Uniformity | High Consistency | Promotes correct crystal transitions (e.g., Cubic Fm3m) |

| Heating Method | Gradual Voltage Increase | Prevents heating element burnout and sample loss |

| Phase Control | Strict Stability | Suppresses amorphous phases and optimizes grain growth |

Elevate Your Materials Synthesis with KINTEK

Precision is non-negotiable when synthesizing complex materials like Ba2M0.4Bi1.6O6. At KINTEK, we understand that your research depends on unwavering thermal stability and uniform heating environments.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require specific crystal transitions or dense microstructural development, our high-temp lab furnaces are fully customizable to meet your unique synthesis protocols.

Ready to achieve superior phase purity? Contact our technical specialists today to find the perfect furnace solution for your laboratory.

References

- Strategic Doping for Precise Structural Control and Intense Photocurrents Under Visible Light in Ba2M0.4Bi1.6O6 (M = La, Ce, Pr, Pb, Y) Double Perovskites. DOI: 10.3390/nano15131039

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are box type electric furnaces used in the ceramics field? Unlock Precision in Firing and Sintering

- What role does a muffle furnace play in SCS of catalysts? Optimize Thermal Initiation for Manganese-Nickel Synthesis

- What is the role of convective heat transfer in a box type resistance furnace? Unlock Efficient Heating Dynamics

- Why is a constant temperature oven better than a heating plate for annealing Cs3Cu2I5:Tb films? Expert Comparison

- What steps should be taken after completing an experiment with a muffle furnace? Ensure Safety and Equipment Longevity

- What are the key safety measures to prioritize when working with benchtop furnaces? Ensure Safe Operation with Expert Guidelines

- What are the main disadvantages of muffle furnaces? Key Trade-offs for Precision Heating

- What are the common applications of box furnaces? Versatile Heat Treatment for Metals, Ceramics, and Research