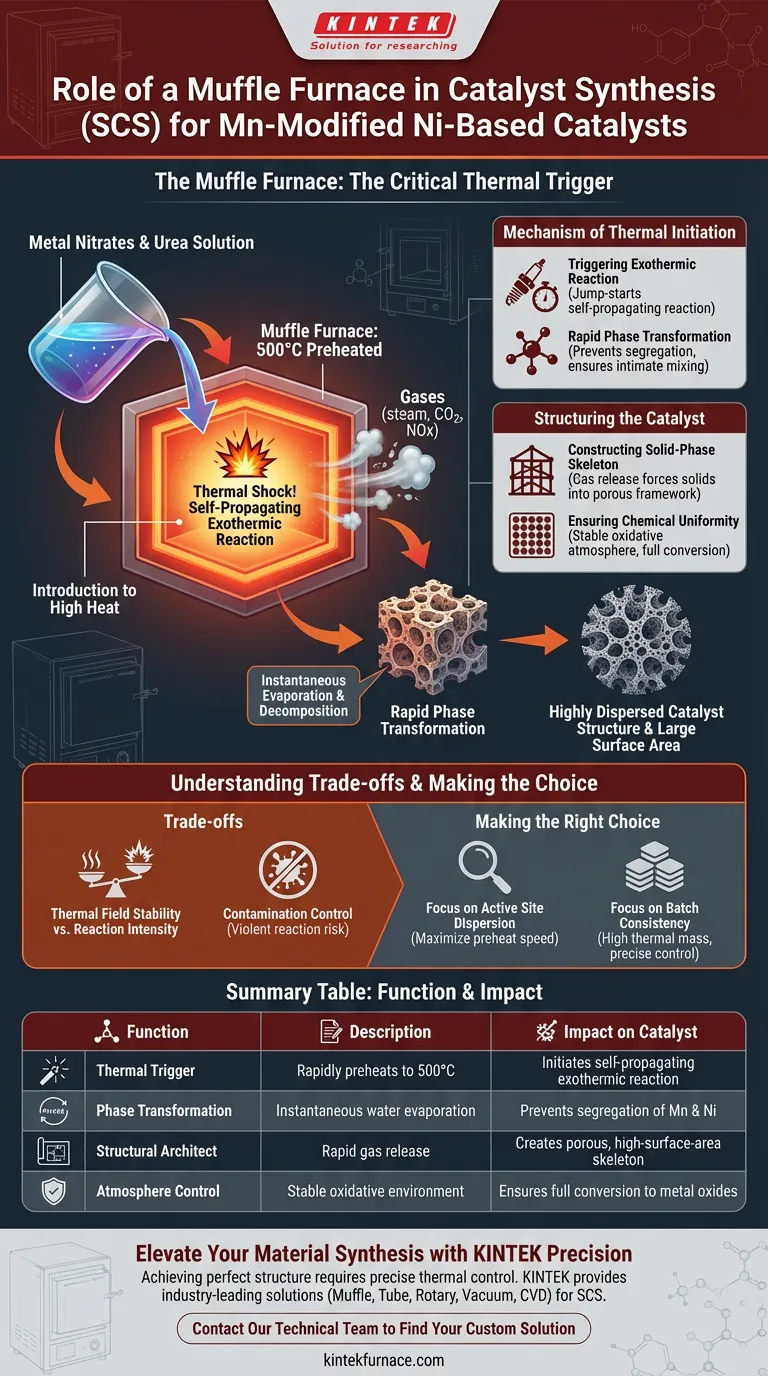

The muffle furnace acts as the critical thermal trigger in the Solution Combustion Synthesis (SCS) of manganese-modified nickel-based catalysts. By introducing a solution of metal nitrates and urea into a chamber preheated to 500 °C, the furnace initiates a vigorous, self-propagating exothermic reaction that rapidly converts liquid precursors into solid catalyst powders.

The muffle furnace provides the precise high-temperature environment required to instantly evaporate water and decompose salts. This rapid thermal shock constructs a solid-phase skeleton, resulting in a highly dispersed catalyst structure that slow-heating methods cannot achieve.

The Mechanism of Thermal Initiation

Triggering the Exothermic Reaction

The primary function of the muffle furnace in this specific synthesis is to provide a "thermal shock." The furnace must be preheated to 500 °C before the mixed solution is introduced.

This immediate exposure to high heat causes the urea fuel and metal nitrates to ignite. The furnace does not just heat the sample; it jump-starts a self-propagating reaction that generates its own internal heat to sustain the process.

Rapid Phase Transformation

Unlike traditional calcination which heats materials slowly, SCS relies on speed. The muffle furnace environment facilitates the almost instantaneous evaporation of water and the decomposition of salts.

This speed is vital. It prevents the components from segregating, ensuring that the manganese and nickel elements remain intimately mixed as they transition from liquid to solid.

Structuring the Catalyst

Constructing the Solid-Phase Skeleton

The violent nature of the reaction within the furnace creates a specific physical structure. As gases are rapidly released during decomposition, they force the forming solids into a porous, skeleton-like framework.

This process establishes the necessary structural foundation for the catalyst. The result is a highly dispersed powder with a large surface area, which is essential for catalytic activity.

Ensuring Chemical Uniformity

While the reaction is self-propagating, the muffle furnace ensures the surrounding environment remains stable. The furnace maintains the oxidative atmosphere required to fully convert metal salts into stable metal oxide phases.

This stability prevents "cold spots" that could lead to incomplete combustion. It guarantees that the interaction between the active components and the support structure is uniform throughout the batch.

Understanding the Trade-offs

Thermal Field Stability vs. Reaction Intensity

While the furnace provides the initial heat, the reaction itself is exothermic and vigorous. If the furnace's internal volume is too small or its temperature recovery is slow, the sudden release of energy from the sample can momentarily destabilize the thermal field.

Contamination Control

Modern electric muffle furnaces are preferred over fuel-based ones because they isolate the sample from combustion byproducts. However, because SCS involves a "violent" reaction, there is a risk of the sample splattering. This requires careful containment within the crucible to prevent cross-contamination of the furnace chamber itself, which could affect future batches.

Making the Right Choice for Your Goal

To optimize the synthesis of manganese-modified nickel-based catalysts, focus on how you utilize the furnace's capabilities.

- If your primary focus is active site dispersion: Ensure the furnace is fully preheated to 500 °C before insertion to maximize the speed of the self-propagating reaction.

- If your primary focus is batch consistency: Use a furnace with high thermal mass and precise electric temperature control to maintain stability despite the exothermic energy release.

The muffle furnace is not merely a heater; it is the architect of the catalyst's skeletal structure, defining its performance through precise thermal initiation.

Summary Table:

| Function | Description | Impact on Catalyst |

|---|---|---|

| Thermal Trigger | Rapidly preheats precursors to 500 °C | Initiates self-propagating exothermic reaction |

| Phase Transformation | Instantaneous water evaporation | Prevents segregation of Mn and Ni elements |

| Structural Architect | Rapid gas release during combustion | Creates a porous, high-surface-area solid skeleton |

| Atmosphere Control | Stable oxidative environment | Ensures full conversion of salts to metal oxides |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect catalyst structure requires more than just heat—it requires precise thermal control and reliability. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of Solution Combustion Synthesis (SCS).

Backed by expert R&D and manufacturing, our equipment ensures the stable thermal fields necessary for consistent, high-dispersion catalyst production. Whether you are scaling up nickel-based catalyst synthesis or exploring new material skeletons, KINTEK’s lab furnaces deliver the performance your research deserves.

Ready to optimize your synthesis process? Contact our technical team today to find your custom solution.

Visual Guide

References

- Alua M. Manabayeva, С.А. Тунгатарова. Dry Reforming of Methane over Mn-modified Ni-based Catalysts. DOI: 10.1007/s10562-024-04676-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an industrial box resistance furnace facilitate the calcination of Mn-Zn ferrite? Boost Process Stability

- What is the mechanism of a laboratory convection furnace for H13 DED steel? Mastering Heat Treatment Precision

- What is the function of a laboratory muffle furnace in the annealing process? Master Stress Relief and Stability

- Why is a high-temperature laboratory furnace used for the recalcination of deactivated LDH catalysts? Restore Performance

- What role do muffle furnaces play in the pretreatment of medical samples? Essential for Accurate Elemental Analysis

- What industries commonly use electric muffle furnaces? Essential for Precise High-Temp Processing

- Why is the separation of chambers important in a muffle furnace? Ensure Purity and Uniform Heating

- What is the technical significance of the calcination process using a muffle furnace? Optimize TiO2 Nanopowders