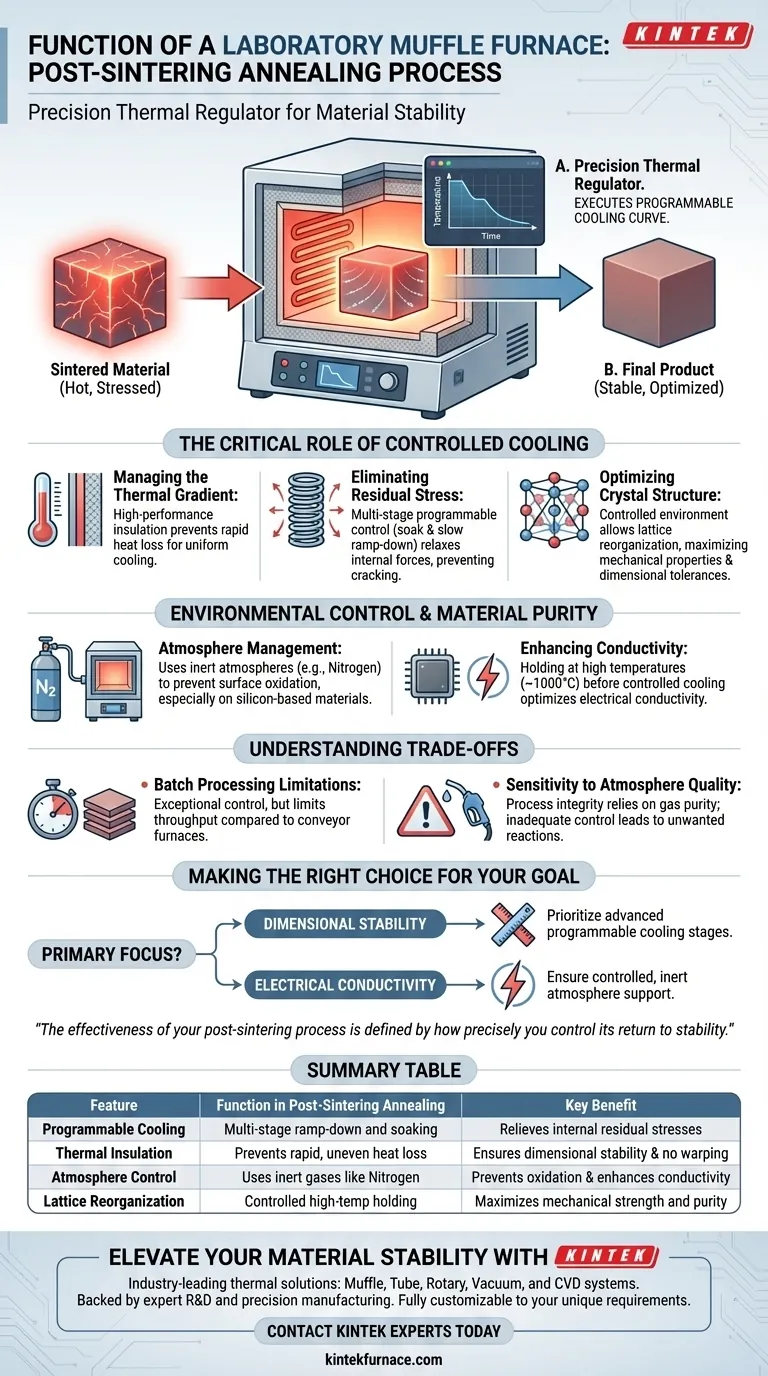

A laboratory muffle furnace serves as a precision thermal regulator during the post-sintering annealing phase, specifically designed to manage the material's return to ambient temperature. Its primary function is to execute a multi-stage, programmable cooling curve that gradually relieves internal residual stresses generated during the initial sintering process.

While sintering creates the solid mass, annealing defines its longevity. The muffle furnace utilizes high-performance insulation and logic-controlled heating elements to ensure the cooling rate is slow and uniform, thereby locking in dimensional stability and mechanical strength.

The Critical Role of Controlled Cooling

Managing the Thermal Gradient

The transition from high sintering temperatures to room temperature is critical. A muffle furnace uses high-performance insulation to prevent rapid heat loss, ensuring the material does not cool unevenly.

Eliminating Residual Stress

Materials often emerge from sintering with significant internal tension. The furnace’s multi-stage programmable control allows for a specific "soak" and slow ramp-down, which relaxes these internal forces and prevents future cracking or warping.

Optimizing Crystal Structure

Beyond simple stress relief, this controlled environment allows for the reorganization of the material's atomic lattice. This structural optimization is essential for maximizing mechanical properties and ensuring the final product meets precise dimensional tolerances.

Environmental Control and Material Purity

Atmosphere Management

Annealing often requires isolation from standard air to prevent degradation. Muffle furnaces can maintain specific atmospheres, such as using nitrogen to prevent surface oxidation on silicon-based materials during the cooling phase.

Enhancing Conductivity

For semiconductor materials, the annealing function is vital for electrical performance. By holding the material at temperatures around 1000°C before controlled cooling, the furnace helps optimize electrical conductivity effectively.

Understanding the Trade-offs

Batch Processing Limitations

Muffle furnaces are typically designed for batch processing rather than continuous flow. While this offers exceptional control for research and high-precision parts, it effectively limits throughput speed compared to conveyor-style industrial furnaces.

Sensitivity to Atmosphere Quality

While these furnaces can utilize protective atmospheres, the integrity of the process relies heavily on the purity of the gas used. Inadequate atmosphere control during the annealing phase can lead to unwanted surface reactions, such as oxidation, negating the benefits of the thermal treatment.

Making the Right Choice for Your Goal

To maximize the utility of a muffle furnace in your post-sintering workflow, consider your specific material requirements:

- If your primary focus is Dimensional Stability: Prioritize a furnace with advanced programmable cooling stages to ensure gradual stress relief and prevent warping.

- If your primary focus is Electrical Conductivity: Ensure your furnace supports a controlled, inert atmosphere (like nitrogen) to prevent oxidation during the annealing cycle.

The effectiveness of your post-sintering process is defined not by how hot you can get the material, but by how precisely you can control its return to stability.

Summary Table:

| Feature | Function in Post-Sintering Annealing | Key Benefit |

|---|---|---|

| Programmable Cooling | Multi-stage ramp-down and soaking | Relieves internal residual stresses |

| Thermal Insulation | Prevents rapid, uneven heat loss | Ensures dimensional stability & no warping |

| Atmosphere Control | Uses inert gases like Nitrogen | Prevents oxidation & enhances conductivity |

| Lattice Reorganization | Controlled high-temp holding | Maximizes mechanical strength and purity |

Elevate Your Material Stability with KINTEK

Don't let residual stress compromise your research or production. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by expert R&D and precision manufacturing. Whether you need to optimize electrical conductivity or ensure perfect dimensional tolerances, our furnaces are fully customizable to meet your unique laboratory requirements.

Ready to refine your annealing process? Contact KINTEK experts today to find the perfect high-temperature furnace for your needs!

Visual Guide

References

- Dimple Dimple, Priyanka Verma. Visible‐NIR Light‐Driven Hydrogen Evolution from Ammonia Borane Using Defect‐Engineered Pd/WO<sub>3‐x</sub> Catalyst. DOI: 10.1002/cctc.202500795

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the typical technical specifications of a muffle furnace? Key Specs for Precise Heating

- Why is a precision-controlled muffle furnace necessary for RuO2/g-C3N4 heat treatment? Ensure Perfect Catalysts

- What certifications does the muffle furnace have? Ensure Compliance and Safety for Your Lab

- How is a digital muffle furnace used to determine material properties? Unlock Precise Thermal Analysis for Your Lab

- What functions do muffle furnaces serve in the petrochemical industry? Essential Catalyst Prep and Quality Control

- What is the role of a muffle furnace in the synthesis of Gold Nanoparticles supported on Bamboo Biochar (Au-NPs/BC)?

- What are some common industrial applications of muffle furnaces? Unlock Precision Heat for Your Materials

- What is the primary function of a Muffle Furnace during the initial stages of lignin and humic substance extraction?