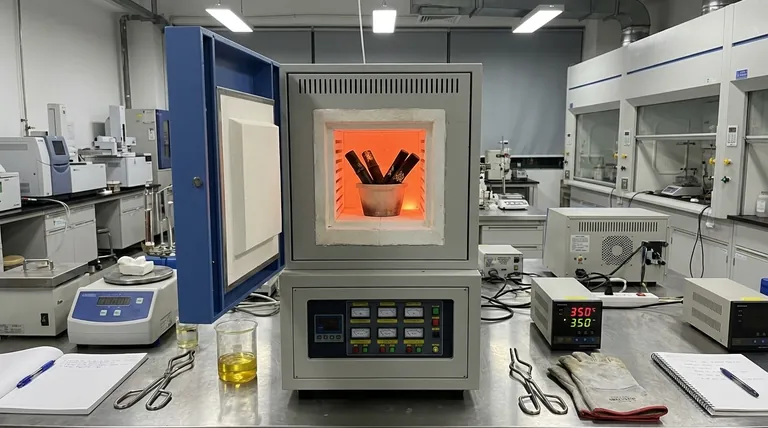

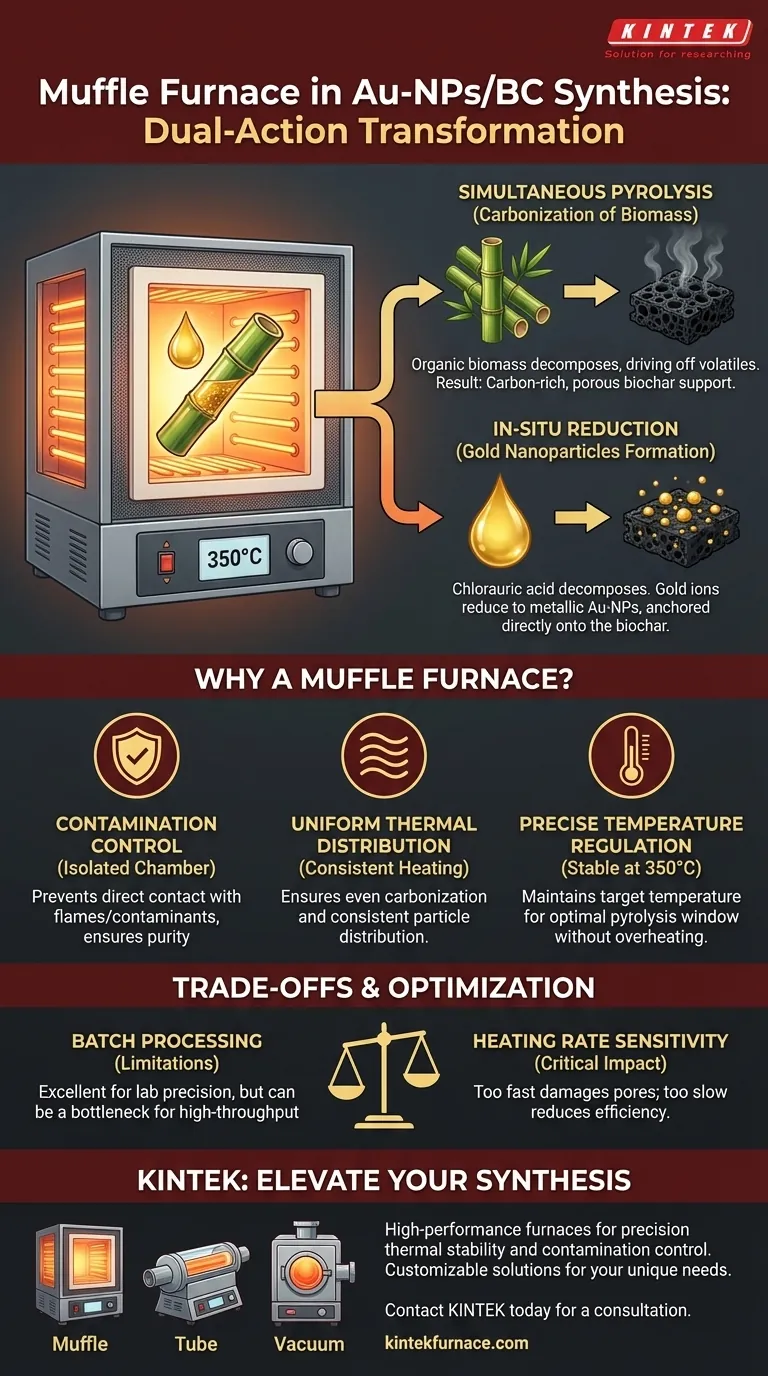

The role of a muffle furnace in this specific synthesis is to provide the high-temperature environment required for simultaneous pyrolysis and reduction. Specifically, by heating bamboo stalks impregnated with chlorauric acid to 350°C, the furnace carbonizes the biomass into biochar while thermally decomposing the gold precursor to load gold nanoparticles onto the support.

The muffle furnace facilitates a dual-action synthesis: it converts raw organic material into a stable carbon structure and anchors gold nanoparticles in a single, controlled thermal step, ensuring a tightly integrated composite.

The Mechanism of Transformation

Carbonization of Biomass

The primary function of the furnace is to facilitate the carbonization of the bamboo. When the impregnated bamboo stalks are subjected to 350°C, the organic biomass undergoes pyrolysis.

This thermal decomposition drives off volatile components. The result is biochar, a carbon-rich solid that serves as the porous support structure for the composite material.

In-Situ Reduction of Gold

Simultaneously, the furnace environment promotes the chemical reduction of the gold precursor. As the temperature rises, the chlorauric acid decomposes.

This process reduces gold ions into metallic gold nanoparticles (Au-NPs). Because this happens alongside carbonization, the nanoparticles are loaded in-situ directly onto the biochar surface.

Why a Muffle Furnace is Used

Contamination Control

A defining feature of a muffle furnace is the isolation of the reaction chamber (the "muffle") from the heating elements and combustion byproducts.

This isolation prevents direct contact with flames or external contaminants. For synthesizing nanomaterials like Au-NPs/BC, maintaining the purity of the chemical environment is essential for consistent particle formation.

Uniform Thermal Distribution

Muffle furnaces utilize electric heating elements combined with thermal convection and radiation to heat the chamber.

This ensures uniform heating throughout the sample. Uniformity is critical to ensure that the bamboo carbonizes evenly and that the gold nanoparticles are distributed consistently across the biochar support.

Precise Temperature Regulation

The synthesis requires a specific target temperature of 350°C. Muffle furnaces are designed to reach and maintain stable temperatures through heavy insulation and controlled heating.

This stability ensures the process remains within the pyrolysis window without overheating, which could degrade the biochar structure or alter the morphology of the nanoparticles.

Understanding the Trade-offs

Batch Processing Limitations

Muffle furnaces are typically batch-processing units. This means you must load, heat, cool, and unload the furnace for each synthesis cycle.

While excellent for laboratory scale and precise control, this can be a bottleneck for high-throughput manufacturing compared to continuous flow reactors.

Heating Rate Sensitivity

The rate at which the furnace ramps up to 350°C impacts the final material properties.

If the furnace heats too quickly, rapid outgassing can damage the pore structure of the biochar. If it heats too slowly, the efficiency of the synthesis drops.

Making the Right Choice for Your Goal

To optimize your synthesis of Au-NPs/BC, consider the following based on your project priorities:

- If your primary focus is material purity: Rely on the muffle furnace’s isolated chamber to prevent oxidation and external contamination during the reduction process.

- If your primary focus is composite stability: Ensure the furnace maintains a steady 350°C to guarantee the complete carbonization of the bamboo, which secures the gold nanoparticles to the surface.

The muffle furnace is not just a heater; it is the integration tool that synchronizes the chemical reduction of gold with the structural evolution of the biochar.

Summary Table:

| Feature | Role in Au-NPs/BC Synthesis |

|---|---|

| Temperature Control | Maintains stable 350°C for optimal carbonization and reduction |

| Chamber Isolation | Prevents contamination, ensuring high purity of gold nanoparticles |

| Heating Mechanism | Provides uniform thermal distribution for consistent particle loading |

| Dual-Action Process | Enables simultaneous biomass pyrolysis and in-situ gold reduction |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is non-negotiable when synthesizing advanced composites like Au-NPs/BC. KINTEK’s high-performance Muffle, Tube, and Vacuum furnaces provide the thermal stability and contamination control required for successful in-situ reduction and pyrolysis.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory needs. Whether you require precise atmosphere control for biochar production or uniform heating for nanoparticle distribution, we have the solution.

Ready to optimize your heat treatment process? Contact KINTEK today for a consultation and discover how our advanced heating technology can drive your research forward.

Visual Guide

References

- Synthesis and characterization of gold nanoparticle-mediated bamboo biochar nanocomposite-based electrode and analysis of its electrochemical behavior. DOI: 10.56042/ijbb.v62i2.12109

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are box type electric furnaces utilized in laboratory research? Enhance Precision in Material Synthesis and Testing

- How does a Muffle Furnace facilitate the formation of Ru-2 cluster catalysts? Precision for Ruthenium Calcination

- What role does a high-temperature muffle furnace play in TiO2 and PEN cross-linking? Unlock High-Performance Hybrids

- What are the common applications of ceramic furnaces? Essential for Electronics, Aerospace, and More

- What is the function of a high-temperature muffle furnace? Master Eggshell Adsorbent Activation

- What are some general-purpose uses of a muffle furnace? Essential for High-Purity Material Processing

- What is the function of a high-temperature box-type resistance furnace in rGO synthesis? Optimize Your Carbonization

- Why is a high-temperature box resistance furnace with argon gas protection necessary for CoCrFeMnNi homogenization?