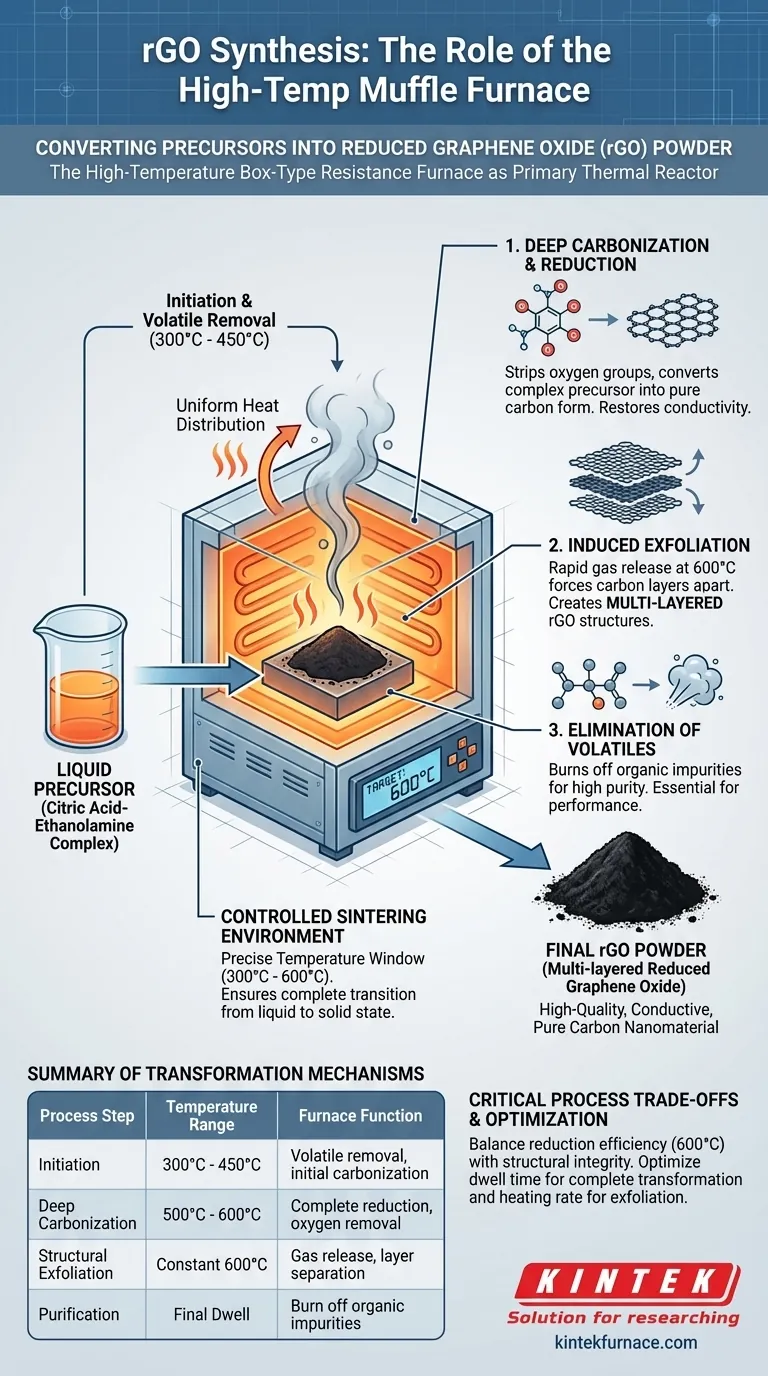

The high-temperature box-type resistance furnace acts as the primary thermal reactor for the deep carbonization and chemical reduction of rGO precursors. Specifically, it provides a controlled sintering environment that heats citric acid-ethanolamine complexes to temperatures between 300°C and 600°C. This thermal energy drives the simultaneous transformation and exfoliation of the liquid precursor into a solid, multi-layered reduced graphene oxide (rGO) residue.

By stabilizing the temperature at exactly 600°C, the furnace ensures the complete transition from a liquid chemical complex to a high-performance carbon nanomaterial. It facilitates the removal of non-carbon elements and the structural reorganization required to produce high-quality rGO powder.

The Role of Thermal Environment in rGO Synthesis

To understand the furnace's function, one must look beyond simple heating. The device creates a precise, isolated environment that dictates the chemical evolution of the material.

Controlled Sintering Range

The furnace operates within a critical temperature window of 300°C to 600°C.

This specific range is calibrated to induce deep carbonization. Temperatures below this threshold may fail to initiate the necessary chemical breakdown, while the upper limit ensures the reaction reaches completion.

From Liquid to Solid State

The furnace facilitates a drastic phase change.

The process begins with a liquid precursor—specifically a citric acid-ethanolamine complex. Through sustained heating, the furnace drives off volatiles and solidifies the remaining carbon structure into a black residue.

Uniform Heat Distribution

The "box-type" design of the muffle furnace ensures the material is heated evenly from all sides.

This uniformity is essential for consistent batch quality. It prevents thermal gradients that could lead to uneven reduction or partial carbonization within the same sample.

Mechanisms of Transformation

The heat provided by the furnace triggers specific chemical mechanisms that define the properties of the final rGO powder.

Deep Carbonization and Reduction

The primary function of the heat treatment is to strip oxygen-containing groups from the precursor.

This "deep carbonization" effectively reduces the material, converting the chemically complex precursor into a more pure carbon form. This reduction restores the conductive properties associated with graphene.

Induced Exfoliation

Crucially, the thermal processing at 600°C does not just burn the material; it exfoliates it.

The rapid release of gases during decomposition forces the carbon layers apart. This results in multi-layered reduced graphene oxide, rather than a dense, non-porous block of carbon.

Elimination of Volatiles

Similar to its role in ceramic processing, the furnace ensures the removal of organic impurities.

By maintaining high temperatures, the furnace burns off the organic components of the complex, leaving behind the desired carbon skeleton. This purification is vital for achieving the high performance expected of rGO nanomaterials.

Critical Process Trade-offs

While the furnace is a powerful tool, the process relies on strict adherence to temperature parameters.

Temperature vs. Material Integrity

There is a trade-off between reduction efficiency and structural integrity.

The primary reference highlights 600°C as the optimal point for "complete transformation." Deviating significantly from this setpoint risks incomplete reduction (if too low) or potential thermal damage to the graphene structure (if excessively high).

Process Time and Energy

Achieving deep carbonization requires sustained energy input.

Unlike flash processes, the muffle furnace method relies on a stable "sintering environment." This requires time for the heat to penetrate the precursor and for the chemical reactions to fully resolve, necessitating a balance between throughput speed and material quality.

Optimizing Your rGO Production

When utilizing a resistance furnace for rGO synthesis, focus on the specific thermal requirements of your precursor.

- If your primary focus is complete reduction: Ensure your furnace can maintain a stable dwell time at 600°C to guarantee the full transformation of the citric acid-ethanolamine complex.

- If your primary focus is structural exfoliation: Verify that the heating rate is sufficient to induce the gas release necessary to separate the carbon layers into a multi-layered structure.

The furnace is not merely a heater; it is the environment that dictates the purity, structure, and ultimate performance of your reduced graphene oxide.

Summary Table:

| Process Step | Temperature Range | Furnace Function |

|---|---|---|

| Initiation | 300°C - 450°C | Volatile removal and initial carbonization of liquid complexes. |

| Deep Carbonization | 500°C - 600°C | Complete chemical reduction and removal of oxygen-containing groups. |

| Structural Exfoliation | Constant 600°C | Gas release induction to create multi-layered rGO structures. |

| Purification | Final Dwell | Burning off organic impurities to leave a pure carbon skeleton. |

Maximize Your Nanomaterial Precision with KINTEK

Achieving the perfect 600°C sintering environment is critical for high-performance rGO production. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, and Vacuum furnaces, specifically designed for deep carbonization and chemical vapor deposition (CVD).

Why choose KINTEK?

- Expert R&D: Our systems ensure uniform heat distribution for consistent batch quality.

- Customizable Solutions: High-temp furnaces tailored to your specific precursor requirements.

- Proven Reliability: Built for the rigorous demands of material science laboratories.

Ready to elevate your synthesis process? Contact our experts today to find the perfect customizable furnace for your unique research needs!

Visual Guide

References

- R. Karunakaran, R. Shanmugasundaram. Insight into unusual complex thermodynamical behaviour of citric acid and ethanolamine solution. DOI: 10.1007/s43939-025-00192-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the primary function of a muffle furnace in g-C3N4/Bi2WO6 preparation? Expert Guide to Thermal Synthesis

- What materials are used in the muffle furnace? A Guide to Critical Components and Performance

- Why are muffle furnaces considered versatile in industrial and laboratory settings? Unlock Precision Heating for Diverse Applications

- What types of heat transfer occur in a box-type resistance furnace? Master Radiation and Convection for Optimal Heating

- What is the purpose of using a high-temperature muffle furnace for NiFe2O4 catalyst precursors? Pure Spinel Formation

- Why is cooling rate control critical in high-temp box furnaces? Ensure Precise Material Comparison & Phase Stability

- How is a high-temperature box resistance furnace utilized in the self-ignition process? Enhance Catalyst Performance

- What type of temperature control does the basic muffle furnace have? Discover Simple, Accurate Heating Solutions