At its core, a muffle furnace is an assembly of specialized materials, each chosen for a distinct role in generating, containing, and controlling extreme temperatures. The primary materials are advanced ceramics for the inner chamber, high-resistance metal alloys for the heating elements, dense fiber insulation, and a structural steel outer casing.

A muffle furnace is not a single entity but a system of carefully selected materials. The inner chamber material dictates chemical compatibility and purity, the heating elements define the maximum temperature, and the insulation determines efficiency and safety.

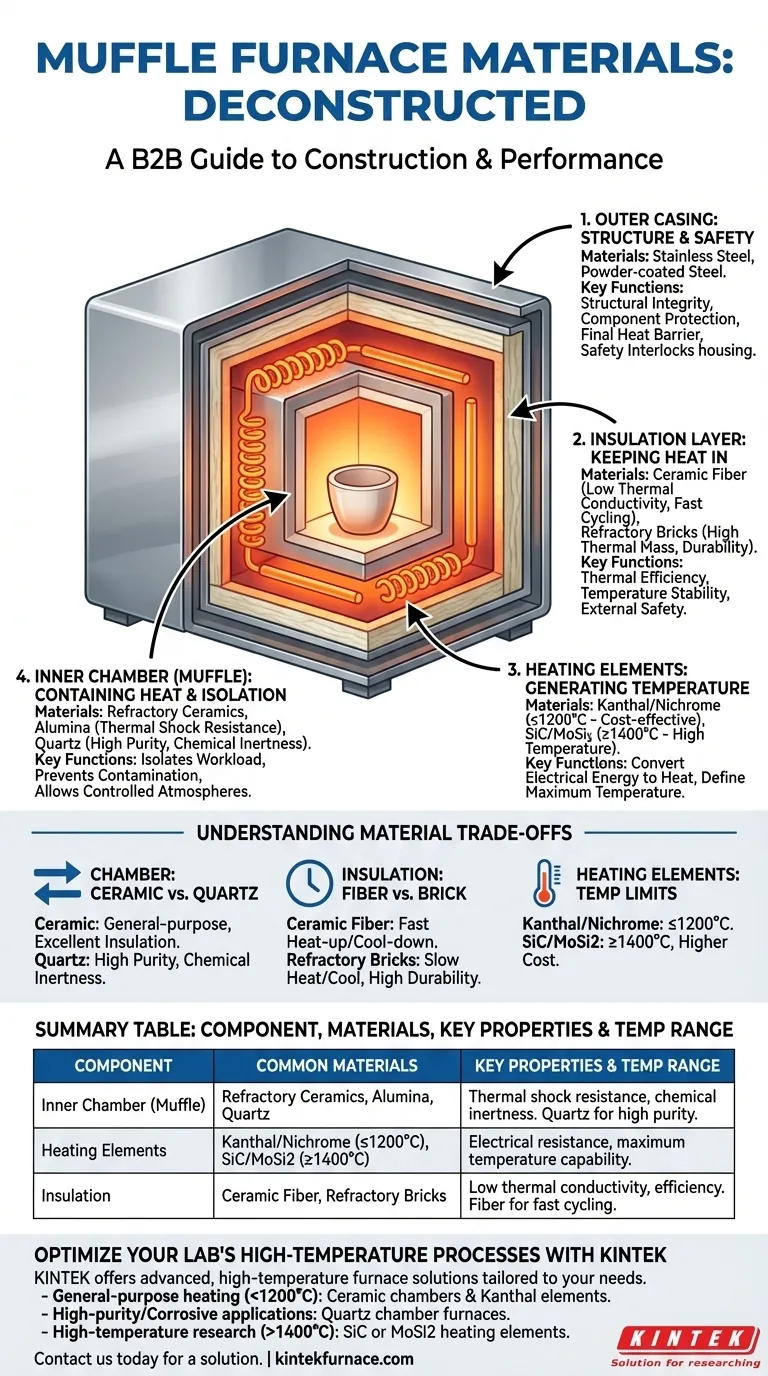

Deconstructing the Furnace: A Material-by-Material Breakdown

To understand a muffle furnace is to understand its constituent parts and the materials that enable their function. Each component solves a specific physics problem related to heat.

The Inner Chamber (Muffle): Containing the Heat

The muffle is the heart of the furnace—a sealed chamber that isolates the workload from the heating elements. This isolation prevents contamination and allows for controlled atmospheres.

Materials like refractory ceramics, alumina, and polycrystalline mullite fiber are most common. They are chosen for exceptional thermal shock resistance and chemical stability at high temperatures.

For applications requiring high purity or resistance to chemical corrosion, a quartz chamber may be used instead.

The Heating Elements: Generating the Temperature

Heating elements are essentially wires or rods that convert electrical energy into heat through high electrical resistance.

Common materials include Kanthal (an iron-chromium-aluminum alloy) and Nichrome (a nickel-chromium alloy). These are cost-effective and reliable for temperatures typically up to 1200°C.

For higher temperatures, more advanced materials are required, such as Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2), which can operate well above 1500°C.

The Insulation Layer: Keeping the Heat In

Effective insulation is critical for thermal efficiency, temperature stability, and external safety. Without it, the furnace would consume enormous amounts of power and be hazardous to touch.

The most common insulation is lightweight ceramic fiber (like mineral wool), which has very low thermal conductivity. In some heavy-duty or older models, dense refractory bricks are used for their durability and thermal mass.

The Outer Casing: Providing Structure and Safety

The outer shell provides structural integrity, protects the delicate internal components, and acts as the final barrier for heat.

This casing is almost always made of stainless steel or powder-coated steel. It houses the controls, wiring, and safety interlocks, such as a door switch that cuts power to the heating elements when opened.

Understanding the Trade-offs: How Material Choice Defines Performance

The selection of these materials is a series of deliberate engineering trade-offs. The materials in a furnace directly define its capabilities, limitations, and cost.

Chamber Material: Ceramic vs. Quartz

A standard ceramic muffle is perfect for general-purpose applications like ashing, heat-treating metals, or firing ceramics. It offers excellent insulation and durability.

A quartz muffle is specified for processes where chemical inertness and purity are paramount, such as in semiconductor research or when working with highly corrosive substances.

Insulation: Fiber vs. Brick

Ceramic fiber insulation allows for faster heat-up and cool-down times due to its low thermal mass. This makes it ideal for labs where cycles are run frequently throughout the day.

Refractory bricks have high thermal mass, meaning they heat and cool very slowly. While less common in modern lab furnaces, their durability makes them suitable for harsh industrial environments with continuous operation.

Heating Elements and Temperature Limits

The choice of heating element is the primary factor determining the furnace's maximum operating temperature.

Kanthal and Nichrome elements are the workhorses for applications below 1200°C. Pushing them beyond their limits causes rapid degradation and failure.

SiC and MoSi2 elements are required for high-temperature metallurgy, glass development, and advanced ceramics research, but they significantly increase the furnace's cost and complexity.

Making the Right Choice for Your Application

Selecting a furnace begins with a clear understanding of your process requirements. The materials of construction are not an afterthought; they are the defining feature.

- If your primary focus is general-purpose heat treatment or ashing (under 1200°C): A furnace with a standard ceramic muffle and Kanthal or Nichrome elements is the most practical and cost-effective choice.

- If your primary focus is high-purity processing or working with corrosive materials: You must specify a furnace with a quartz chamber to ensure process integrity.

- If your primary focus is achieving very high temperatures (above 1400°C): Your only option is a furnace equipped with specialized Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) heating elements.

By matching the furnace's materials to your goal, you ensure reliable, efficient, and safe operation.

Summary Table:

| Component | Common Materials | Key Properties & Temperature Range |

|---|---|---|

| Inner Chamber (Muffle) | Refractory Ceramics, Alumina, Quartz | Thermal shock resistance, chemical inertness. Quartz for high purity. |

| Heating Elements | Kanthal/Nichrome (≤1200°C), SiC/MoSi2 (≥1400°C) | Electrical resistance, maximum temperature capability. |

| Insulation | Ceramic Fiber, Refractory Bricks | Low thermal conductivity, efficiency. Fiber for fast cycling. |

Optimize Your Lab's High-Temperature Processes with KINTEK

Selecting the right muffle furnace is critical for your research or production outcomes. The materials of construction directly determine temperature capabilities, chemical compatibility, and long-term reliability.

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities.

Let us help you make the right choice:

- General-purpose heating (<1200°C): We offer robust furnaces with ceramic chambers and Kanthal elements.

- High-purity/Corrosive applications: Our quartz chamber furnaces ensure process integrity.

- High-temperature research (>1400°C): We supply furnaces with specialized SiC or MoSi2 heating elements.

Contact us today to discuss your specific requirements and receive a solution that ensures efficient, safe, and precise thermal processing.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO