In essence, a muffle furnace is versatile because it creates an extremely hot, precisely controlled, and clean environment. This unique combination allows it to serve a vast range of applications, from delicate scientific analysis in a laboratory to robust heat-treatment processes in heavy industry. The key is its design, which isolates the material being heated from the contaminants produced by the heat source itself.

The versatility of a muffle furnace stems from a single, powerful design principle: separating the sample from the heating elements. This isolation is what allows one type of equipment to be essential for everything from determining the ash content of a pharmaceutical to hardening steel tools.

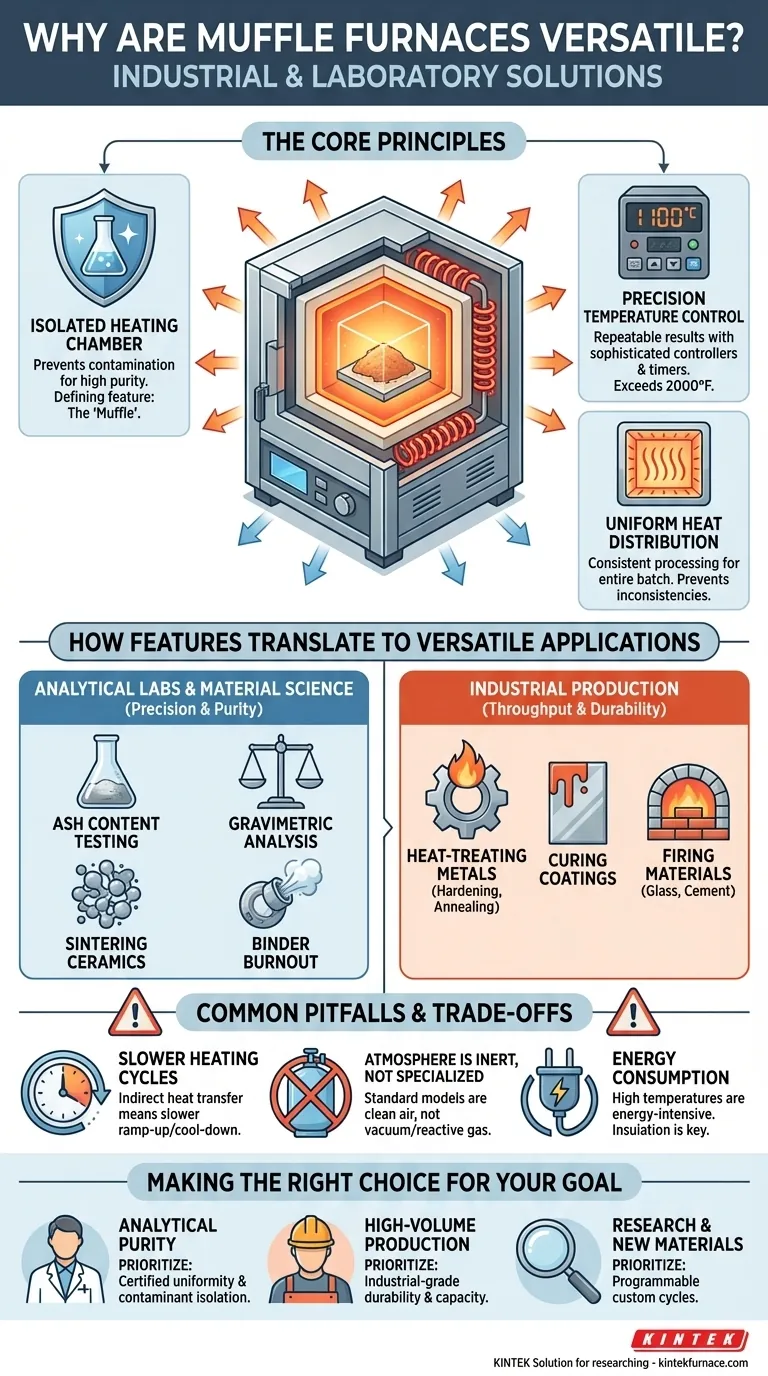

The Core Principles of Muffle Furnace Design

To understand the furnace's adaptability, we must first look at the functional principles that define it. These core features work in concert to deliver reliable, repeatable results across disciplines.

The Isolated Heating Chamber (The "Muffle")

The defining feature of this furnace is the muffle—a sealed inner chamber, typically made of high-temperature ceramic, that contains the sample.

The heating elements are located outside this chamber. This design prevents byproducts of combustion or element degradation from contaminating the material inside, which is critical for analytical purity.

Precision Temperature Control

Modern muffle furnaces are equipped with sophisticated digital controllers, thermostats, and timers.

This allows for precise control over the heating rate, the maximum temperature (which can exceed 1100°C or 2000°F), and the duration of the process. This repeatability is essential for both scientific experiments and standardized quality control.

Uniform Heat Distribution

Quality muffle furnaces are engineered to provide uniform heat throughout the internal chamber.

Consistent temperature ensures that an entire sample or batch of items is processed evenly. This prevents inconsistencies in material testing, sintering, or heat treatment.

How Features Translate to Versatile Applications

The combination of isolation, precision, and uniform heat makes the muffle furnace a go-to tool in numerous fields.

For Analytical Laboratories

In a lab setting, the primary goal is often analysis where purity is paramount. The furnace's clean environment is non-negotiable.

Common uses include ash content testing for materials like pharmaceuticals, polymers, and food, as well as gravimetric analysis where samples are heated to a constant weight.

For Material Science and R&D

Researchers use muffle furnaces to test the properties of materials under extreme thermal stress.

This includes processes like sintering ceramics to increase their strength and density, performing binder burnout from green parts, and developing new alloys through controlled heat-treatment cycles.

For Industrial Production

In industry, the focus shifts to durability and throughput. Furnaces are used for direct manufacturing and component treatment.

Key applications include heat-treating metals to harden, anneal, or temper them; curing coatings; and firing materials in the production of glass, cement, and ceramics.

Understanding the Key Distinction: Lab vs. Industrial Models

The term "muffle furnace" covers a wide spectrum of equipment tailored to different operational scales.

Laboratory Furnaces: Precision and Purity

These are typically smaller, benchtop units. They are designed for maximum temperature accuracy and uniformity for analytical processes and small-scale experiments.

Industrial Furnaces: Throughput and Durability

Industrial models are larger, more robust, and built for higher volumes and continuous operation. While still precise, they are optimized for the rigors of a production environment.

Common Pitfalls and Trade-offs

While highly versatile, a muffle furnace is not the solution for every heating application. Understanding its limitations is key to using it effectively.

Slower Heating and Cooling Cycles

Because heat must transfer indirectly through the muffle chamber walls, these furnaces can have slower ramp-up and cool-down times compared to direct-heating kilns.

Atmosphere is Inert, Not Specialized

A standard muffle furnace provides a clean air atmosphere, preventing contamination from the heat source. However, it does not create a vacuum or a specific reactive gas environment (like argon or nitrogen) without significant and specialized modifications.

Energy Consumption

Reaching and maintaining very high temperatures is energy-intensive. The efficiency of the insulation is a critical factor in the operational cost of any muffle furnace.

Making the Right Choice for Your Goal

To select the correct tool, you must match the furnace's capabilities to your primary objective.

- If your primary focus is analytical purity and material testing: Prioritize a laboratory furnace with certified temperature uniformity and excellent contaminant isolation.

- If your primary focus is high-volume production or robust heat treatment: Select an industrial-grade furnace designed for durability, capacity, and the specific temperature range your process requires.

- If your primary focus is research on new materials: Seek a programmable model that allows you to design custom, multi-stage heating and cooling cycles for processes like sintering or binder burnout.

Ultimately, understanding these core principles empowers you to see the muffle furnace not just as a hot box, but as a precise instrument for manipulating matter.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Isolated Heating Chamber | Prevents contamination, ensures purity | Ash content testing, gravimetric analysis |

| Precision Temperature Control | Enables repeatable processes | Material sintering, heat treatment cycles |

| Uniform Heat Distribution | Ensures consistent results | Curing coatings, firing ceramics |

Ready to enhance your lab or industrial processes with a tailored muffle furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our solutions can deliver precise temperature control, uniform heating, and contaminant-free environments for your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?