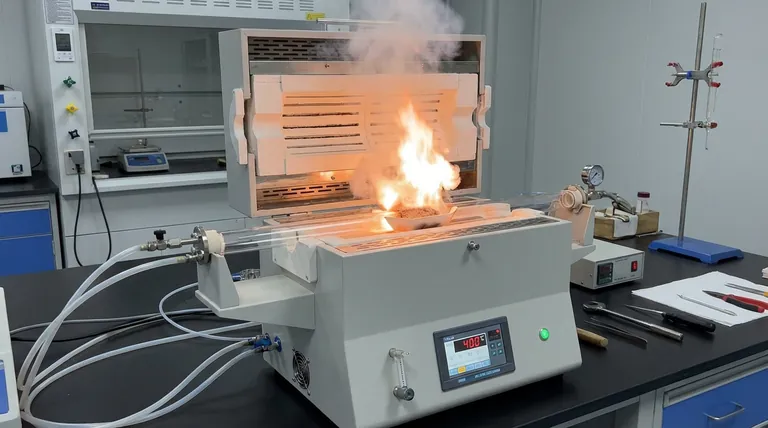

A high-temperature box resistance furnace acts as the precise thermal trigger required to initiate the self-ignition combustion synthesis of iron-doped ceria catalyst precursors. By maintaining a constant temperature of approximately 400 °C coupled with flowing air, the furnace induces a rapid exothermic reaction in the dried catalyst gel, causing the immediate decomposition of organic components.

The furnace provides more than just heat; it creates a controlled oxidative environment that transforms the rapid release of gases into a structural advantage, generating the high porosity essential for effective catalytic performance.

The Mechanism of Self-Ignition

The Thermal Trigger Point

The primary function of the furnace in this specific process is to provide a "shock" of thermal energy.

Unlike gradual calcination processes, the furnace is set to a constant high temperature of approximately 400 °C.

This specific thermal environment is required to push the dried gel past its activation energy threshold, triggering the self-ignition phenomenon.

Decomposition of Organic Components

Once the ignition point is reached, the organic components within the precursor gel (such as citrates or other complexing agents) serve as fuel.

The furnace heat causes these organics to decompose rapidly.

This decomposition is not a slow burn but an energetic, exothermic event that generates significant internal heat, supplementing the energy provided by the furnace elements.

The Role of Flowing Air

The primary reference highlights the necessity of "flowing air" within the furnace chamber.

This airflow ensures a continuous supply of oxygen, which is critical for maintaining the oxidative environment.

Without sufficient oxygen flow, the combustion of organics would be incomplete, potentially leaving carbon residues rather than pure metal oxides.

Impact on Catalyst Morphology

Generating High Porosity

The utility of the box furnace in this process is directly linked to the physical structure of the final material.

The rapid exothermic reaction triggered by the furnace releases a large volume of gas almost instantaneously.

As these gases escape the solidifying material, they create a network of voids, resulting in a metal oxide powder with high porosity.

Establishing the Oxide Phase

The furnace ensures the transition from a precursor gel to a stable solid.

By facilitating the complete burnout of organics, the process leaves behind a clean iron-doped ceria lattice.

This creates the fundamental "metal oxide" character required for the material to function as a catalyst.

Understanding the Trade-offs

Temperature Precision vs. Reaction Speed

While the reaction is described as "self-ignition," reliance on the furnace's stability is paramount.

If the furnace temperature fluctuates significantly below 400 °C, the reaction may fail to ignite or proceed too slowly, resulting in a dense, non-porous material.

Conversely, uncontrolled heating beyond the target window could lead to sintering, where the pores collapse and surface area is lost.

Pre-treatment Considerations

While the self-ignition occurs at 400 °C, effective use of the furnace often implies a multi-stage approach.

As noted in similar synthesis methods, the furnace may first be used at lower temperatures (e.g., 120 °C) to remove moisture from the wet gel.

Attempting to self-ignite a wet gel without this drying step can lead to uncontrolled splattering or uneven combustion within the furnace chamber.

Making the Right Choice for Your Goal

To maximize the quality of your iron-doped ceria catalyst, align your furnace settings with your specific material requirements:

- If your primary focus is High Porosity: Ensure the furnace is pre-heated and stable at 400 °C before introducing the sample to maximize the speed of gas evolution.

- If your primary focus is Chemical Purity: Verify that the airflow rate is sufficient to fully flush combustion byproducts out of the chamber, preventing carbon contamination.

Success in this process relies on utilizing the furnace not just as a heater, but as a precise reactor for controlled combustion.

Summary Table:

| Process Phase | Furnace Function | Key Outcome |

|---|---|---|

| Pre-treatment | Low-temp heating (120°C) | Moisture removal; prevents splattering |

| Thermal Trigger | Constant 400°C environment | Reaches activation energy for self-ignition |

| Combustion | Continuous flowing air supply | Complete oxidation; removal of carbon residues |

| Morphology | Controlled gas evolution | High porosity and stable metal oxide lattice |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a dense solid and a high-performance porous catalyst. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab requirements. Our high-temperature box furnaces provide the thermal stability and airflow control essential for complex processes like self-ignition combustion synthesis.

Ready to optimize your catalyst production? Contact us today to discuss your custom furnace needs with our engineering team!

References

- Albert Gili, Reinhard Schomäcker. One-pot synthesis of iron-doped ceria catalysts for tandem carbon dioxide hydrogenation. DOI: 10.1039/d4cy00439f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What temperature range can a box furnace operate in? Find the Perfect Fit for Your Lab's Needs

- What features make muffle furnaces easy to operate? Discover Key Ease-of-Use Features

- Why use vacuum muffle furnaces for nitrogen-doped biochar? Essential Atmosphere Control for Photocatalysis

- How is the box furnace's door secured and what safety feature does it have? Ensuring Safe Operation with Robust Design

- How do modern box type high-temperature resistance furnaces address environmental concerns? Boost Efficiency & Drive Sustainability

- What is the primary function of an industrial muffle furnace? Unlock High-Performance Carbon Paper Electrodes

- How does heat distribution differ between muffle furnaces and drying ovens? Uncover Key Insights for Your Lab

- What role does an air vent play in muffle furnaces? Master Atmosphere Control for Precise Results