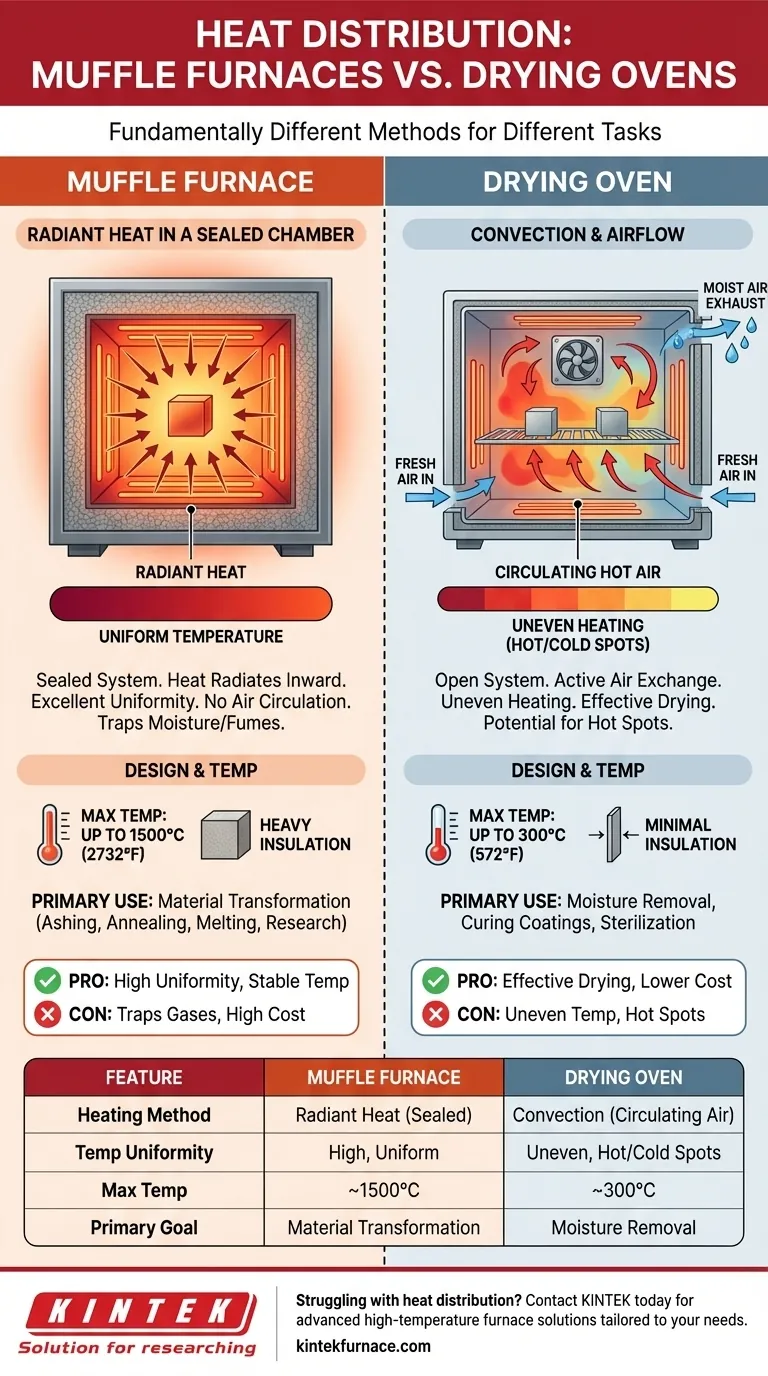

At their core, muffle furnaces and drying ovens distribute heat in fundamentally different ways because they are built for entirely different tasks. Muffle furnaces are engineered for exceptional temperature uniformity through radiant heat in a sealed chamber. In contrast, drying ovens use circulating hot air (convection), which inherently creates temperature variations and potential hot and cold spots throughout the chamber.

The crucial difference lies in their core function: a muffle furnace is designed to transform materials with uniform, high-temperature heat, while a drying oven is designed to remove moisture using circulated air. This distinction in purpose dictates every aspect of their design, from insulation to airflow, and is the root cause of their different heat distribution profiles.

The Core Difference in Heating Method

The way each device generates and moves heat is the primary reason for their performance differences. One prioritizes a static, uniform environment, while the other prioritizes active air exchange.

Muffle Furnaces: Radiant Heat in a Sealed Chamber

A muffle furnace operates as a completely sealed system during a heating cycle. It relies on electric heating elements that line the walls of the chamber.

These elements radiate heat inward, which is then absorbed and reflected by the chamber's heavy insulation. With no air circulating, the temperature stabilizes and becomes extremely uniform throughout the enclosed space.

Drying Ovens: Convection and Airflow

A drying oven is an open system designed for convection. It actively pulls in fresh air, passes it over heating elements (electric or gas), and circulates it throughout the chamber with a fan.

This moving hot air absorbs moisture from the contents and is then exhausted. While this airflow is effective for drying, it is also the source of uneven heating, as areas closer to the fan or heating element will be hotter than corners or obstructed zones.

How Design Dictates Function and Temperature

The physical construction of each unit is tailored to its specific heating method and intended application. This includes the chamber's insulation, size, and ultimate temperature capability.

Chamber Design and Insulation

Muffle furnaces feature smaller, more controlled chambers with thick, heavy-duty insulation. This design is critical for minimizing heat loss and maintaining the stable, high temperatures required for uniform heating.

Drying ovens, by contrast, often have larger chambers with minimal insulation. Since they are designed to constantly exhaust moist air, retaining maximum heat is less of a priority than facilitating airflow.

Temperature Range and Purpose

The robust insulation and radiant heating method allow muffle furnaces to reach extremely high temperatures, often up to 1500°C (2732°F) or more. This makes them ideal for processes like ashing, annealing metals, or materials research.

Drying ovens operate at much lower temperatures, typically topping out around 300°C (572°F). Their function is not to alter the chemical structure of a material but to simply remove moisture, cure coatings, or sterilize equipment.

Understanding the Trade-offs

Choosing between these two tools means understanding the inherent compromises in each design. Neither is universally better; they are simply optimized for different outcomes.

Uniformity vs. Moisture Removal

This is the central trade-off. With a muffle furnace, you gain near-perfect temperature uniformity at the cost of having no mechanism to vent moisture or fumes. Anything that outgasses will remain trapped in the chamber.

With a drying oven, you gain excellent moisture removal capabilities but sacrifice absolute temperature uniformity. You must accept that different parts of your sample may experience slightly different temperatures.

The "Hot Spot" Problem in Ovens

The hot and cold spots in a drying oven are a direct and unavoidable consequence of convection heating. The path of the circulating air dictates the temperature map inside the chamber. This can be a critical issue for sensitive processes where every part of an object must be heated identically.

Cost and Complexity

The materials and engineering required to safely achieve and contain high temperatures make muffle furnaces significantly more expensive than drying ovens. Their heavy insulation, advanced controllers, and robust heating elements contribute to a higher initial cost.

Making the Right Choice for Your Application

To select the correct equipment, you must be clear about your primary objective. Is your goal to heat a material to a precise temperature uniformly, or is it to remove moisture from it?

- If your primary focus is material transformation (ashing, annealing, melting): You require the high, uniform temperatures that only a muffle furnace can provide.

- If your primary focus is removing moisture or curing coatings: The active air circulation of a drying oven is essential for an efficient process.

- If your primary focus is absolute temperature stability for a critical process: A muffle furnace provides a far more controlled and predictable thermal environment, even at lower temperatures.

Ultimately, your choice depends on whether you need to transform the material itself or simply change its condition by drying it.

Summary Table:

| Feature | Muffle Furnace | Drying Oven |

|---|---|---|

| Heating Method | Radiant heat in sealed chamber | Convection with circulating air |

| Temperature Uniformity | High, uniform throughout | Uneven, with hot/cold spots |

| Max Temperature | Up to 1500°C (2732°F) | Up to 300°C (572°F) |

| Primary Use | Material transformation (e.g., ashing, annealing) | Moisture removal, curing, sterilization |

| Insulation | Heavy-duty for heat retention | Minimal to facilitate airflow |

Struggling with heat distribution in your lab processes? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for precision and reliability. With strong deep customization capabilities, we ensure our furnaces meet your unique experimental requirements, whether you need uniform heating for material transformation or efficient drying. Don't let temperature inconsistencies hold you back—contact us today to discuss how KINTEK can enhance your laboratory efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure