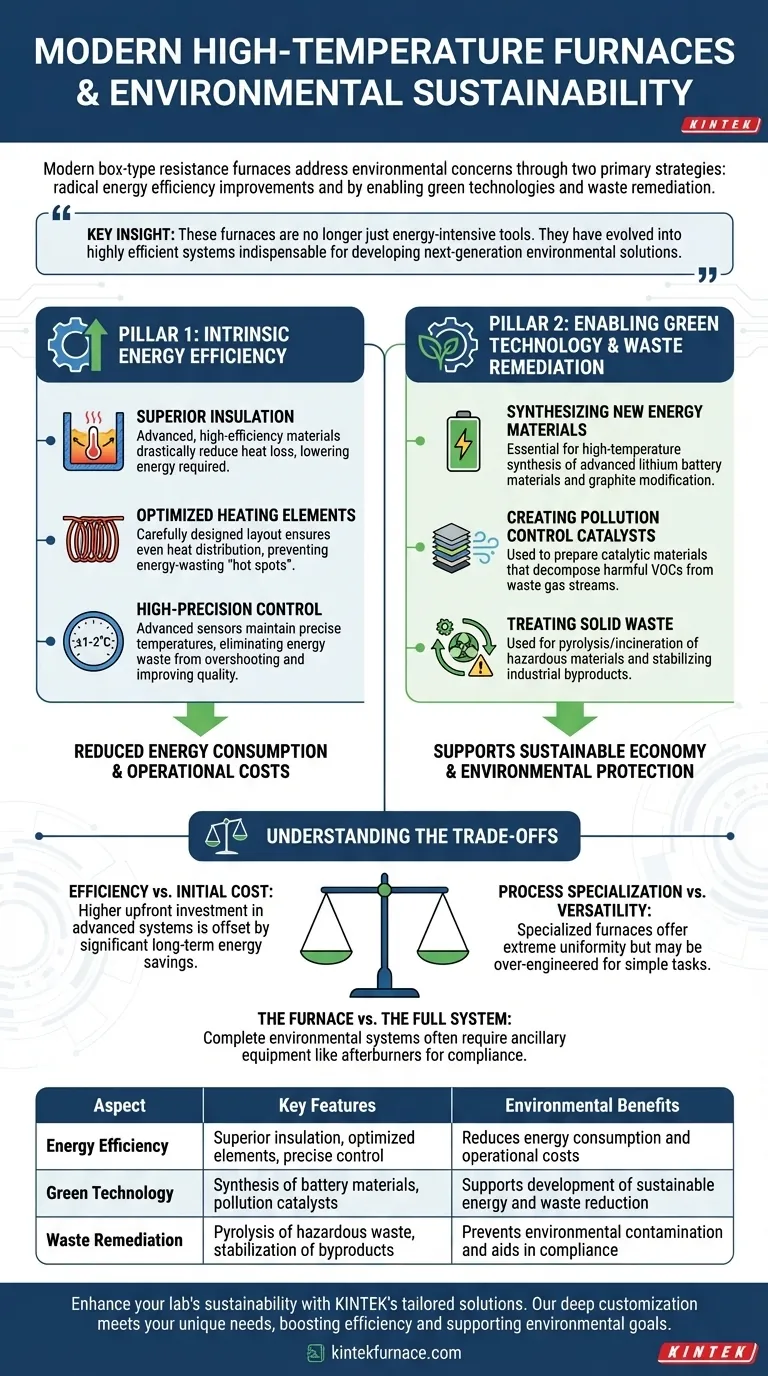

At their core, modern box-type high-temperature resistance furnaces address environmental concerns through two primary strategies: radical improvements in energy efficiency to reduce their own consumption, and their critical role in producing materials and enabling processes for green technologies and waste remediation. This dual approach minimizes their direct environmental footprint while simultaneously serving as an essential tool for broader sustainability initiatives.

The key insight is that these furnaces are no longer just energy-intensive tools. They have evolved into highly efficient systems that are indispensable for developing next-generation environmental solutions, from battery materials to pollution control catalysts.

The Two Pillars of Environmental Performance

The environmental credentials of a modern resistance furnace rest on its internal design and its external application. Understanding both is crucial for a complete assessment.

Pillar 1: Intrinsic Energy Efficiency

The most direct way these furnaces reduce environmental impact is by consuming less energy. This is achieved through sophisticated engineering focused on retaining and precisely applying heat.

Superior Insulation Modern furnaces utilize advanced, high-efficiency insulation materials. These materials drastically reduce heat loss to the surrounding environment, meaning less energy is required to maintain high internal temperatures.

Optimized Heating Elements The physical layout and design of the heating elements are carefully optimized. This ensures heat is distributed evenly and efficiently throughout the chamber, directly improving energy utilization and preventing "hot spots" that waste power.

High-Precision Temperature Control Advanced control systems with high-precision sensors can maintain temperatures with an accuracy of ±1-2°C. This precision eliminates the energy wasted by overshooting the target temperature and ensures a process uses only the exact amount of energy required, improving both efficiency and product quality.

Pillar 2: Enabling Green Technology and Waste Remediation

Beyond their own efficiency, these furnaces are a key enabling technology for a wide range of environmental applications. They are the production workhorses for the materials that drive a sustainable economy.

Synthesizing New Energy Materials They are essential for the high-temperature synthesis of advanced lithium battery materials, such as LiCoO₂ and NCM ternary materials. They are also used to modify graphite for improved battery anode performance.

Creating Pollution Control Catalysts These furnaces are used to prepare catalytic materials, such as platinum supported on Al₂O₃, which are then used in industrial systems to decompose harmful Volatile Organic Compounds (VOCs) from waste gas streams.

Treating Solid Waste In specialized applications, they are used for the pyrolysis and incineration of hazardous materials like medical waste. They can also stabilize industrial byproducts like fly ash, preventing harmful substances from leaching into the environment.

Understanding the Trade-offs

While modern designs are vastly superior, selecting a furnace still involves balancing competing priorities. Objectivity requires acknowledging these trade-offs.

Efficiency vs. Initial Cost

Furnaces built with the most advanced insulation and precision control systems carry a higher upfront purchase price. This initial investment, however, is often offset over the equipment's lifecycle by significant savings in energy costs.

Process Specialization vs. Versatility

A furnace optimized for extreme temperature uniformity (e.g., ±5°C) using features like circulating fans may be ideal for sensitive materials but could be over-engineered and less cost-effective for simple bulk heat treatments.

The Furnace vs. The Full System

For applications like waste treatment or chemical synthesis, the furnace is only one part of the solution. The complete environmental system may require additional ancillary equipment, such as afterburners or exhaust gas scrubbers, which add complexity and cost but are essential for regulatory compliance.

Making the Right Choice for Your Application

Evaluating a furnace requires looking beyond the spec sheet to your specific environmental and process goals.

- If your primary focus is reducing operational costs: Prioritize models with documented low heat loss, superior insulation packages, and high-efficiency heating element designs.

- If your primary focus is advanced material synthesis: Focus on furnaces offering exceptional temperature accuracy (±1°C or better) and proven temperature uniformity across the entire chamber.

- If your primary focus is waste treatment or remediation: Ensure the furnace can be integrated with the necessary off-gas handling and monitoring equipment required for full environmental compliance.

Choosing the right furnace means selecting a tool that is not only effective for your process but also aligns with your long-term sustainability and efficiency goals.

Summary Table:

| Aspect | Key Features | Environmental Benefits |

|---|---|---|

| Energy Efficiency | Superior insulation, optimized heating elements, high-precision control | Reduces energy consumption and operational costs |

| Green Technology | Synthesis of battery materials, pollution control catalysts | Supports development of sustainable energy and waste reduction |

| Waste Remediation | Pyrolysis of hazardous waste, stabilization of byproducts | Prevents environmental contamination and aids in compliance |

Ready to enhance your lab's sustainability with advanced high-temperature furnaces? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, boosting efficiency and supporting your environmental goals. Contact us today to discuss how our furnaces can drive your success!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK