At its core, the primary feature that makes a modern muffle furnace easy to operate is its programmable digital controller. This interface allows you to precisely set, monitor, and automate complex heating and cooling cycles with minimal manual intervention, ensuring your process is both simple to execute and highly repeatable.

While a digital controller is the most visible feature, true operational ease comes from a system of design choices that automate complexity. These include features that ensure uniform heating, protect the sample, and guarantee operator safety, effectively letting the furnace handle the difficult variables for you.

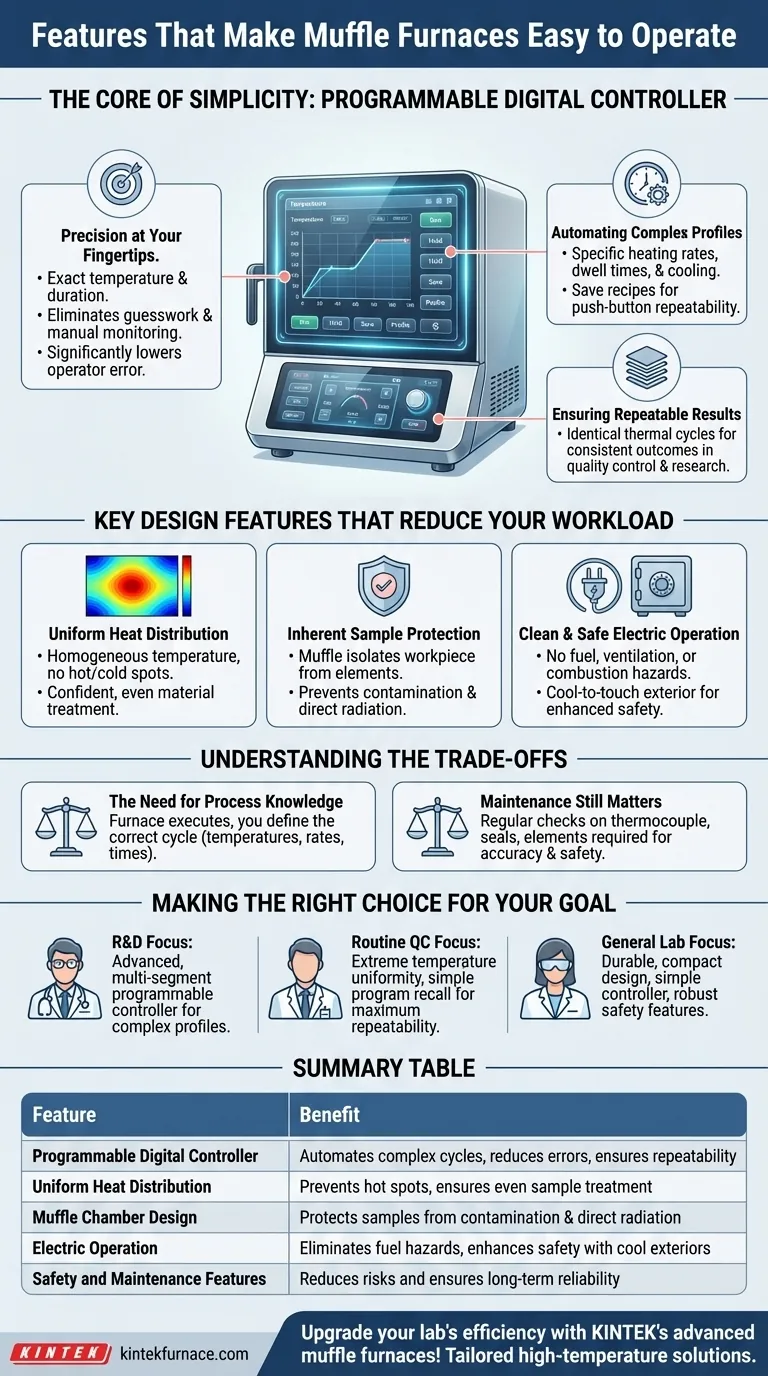

The Core of Simplicity: The Digital Controller

The controller is the brain of the furnace. It transforms a potentially complex thermal process into a manageable, automated task.

Precision at Your Fingertips

Modern digital controllers allow you to set the exact temperature and duration for your process. This eliminates the guesswork and manual monitoring required with older analog systems.

The result is a significantly lower chance of operator error, leading to more consistent outcomes.

Automating Complex Profiles

Many applications require more than just holding a single temperature. They need specific heating rates, dwell times, and controlled cooling rates.

A fully programmable controller automates this entire thermal profile. You can save specific recipes or programs, allowing anyone in the lab to run the exact same process with the push of a button.

Ensuring Repeatable Results

The combination of precise settings and automation makes your results highly reproducible. Whether running a process today or a month from now, the furnace will execute the identical thermal cycle, which is critical for quality control and research applications.

Key Design Features That Reduce Your Workload

Beyond the controller, the furnace's fundamental design plays a huge role in its ease of use by handling inherent challenges without your input.

Uniform Heat Distribution

A well-designed furnace provides homogeneous temperature throughout the entire chamber. This is achieved through the strategic placement of heating elements and the use of materials with high thermal conductivity.

This feature is critical because it means you don't have to worry about "hot spots" or "cold spots" ruining your sample. You can place your material inside with confidence that it will be treated evenly.

Inherent Sample Protection

The defining feature of a muffle furnace is the muffle itself—an interior chamber that isolates your workpiece from the heating elements.

This design inherently protects materials from contamination and direct radiation, simplifying the process. You don't need to create a complex secondary containment system to ensure a clean heating environment.

Clean and Safe Electric Operation

Nearly all modern lab-scale muffle furnaces are electrically powered. This eliminates the need to manage fuel lines, ventilation for fumes, or other hazards associated with combustion.

The furnace's housing is also a key feature, often built from textured stainless steel with thick fiber insulation. This keeps the exterior cool to the touch, enhancing safety and making it more approachable to operate.

Understanding the Trade-offs

"Easy to use" does not mean a complete absence of complexity. It's crucial to understand the limitations to operate the equipment effectively and safely.

The Need for Process Knowledge

The furnace automates the execution of the thermal cycle, but it cannot tell you the correct cycle for your material.

You must still possess the process knowledge to define the right temperatures, heating rates, and dwell times. The furnace is a tool that executes your instructions; the quality of those instructions is up to you.

Maintenance Still Matters

Reliable designs and premium components reduce the frequency of maintenance, but they do not eliminate it.

Regular checks on the thermocouple, door seals, and heating elements are necessary to ensure the furnace continues to operate accurately and safely. Ease of use depends on a well-maintained instrument.

Making the Right Choice for Your Goal

Select a furnace by matching its features to the specific demands of your work.

- If your primary focus is research and development: Prioritize a furnace with a highly advanced, multi-segment programmable controller to create and test complex thermal profiles.

- If your primary focus is routine quality control: Focus on models known for extreme temperature uniformity and simple program recall to ensure maximum repeatability.

- If your primary focus is general-purpose lab use: Look for a durable, compact design with a simple controller and robust safety features like a cool-to-touch exterior.

Ultimately, the right features transform a powerful heat-treating instrument into a reliable and straightforward partner for your work.

Summary Table:

| Feature | Benefit |

|---|---|

| Programmable Digital Controller | Automates complex cycles, reduces errors, and ensures repeatability |

| Uniform Heat Distribution | Prevents hot spots, ensures even sample treatment |

| Muffle Chamber Design | Protects samples from contamination and direct radiation |

| Electric Operation | Eliminates fuel hazards, enhances safety with cool exteriors |

| Safety and Maintenance Features | Reduces risks and ensures long-term reliability |

Upgrade your lab's efficiency with KINTEK's advanced muffle furnaces!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions. Our muffle furnaces, part of a product line including Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, feature strong deep customization to meet your unique experimental needs. Experience precise temperature control, automated operation, and enhanced safety—contact us today to discuss how we can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination