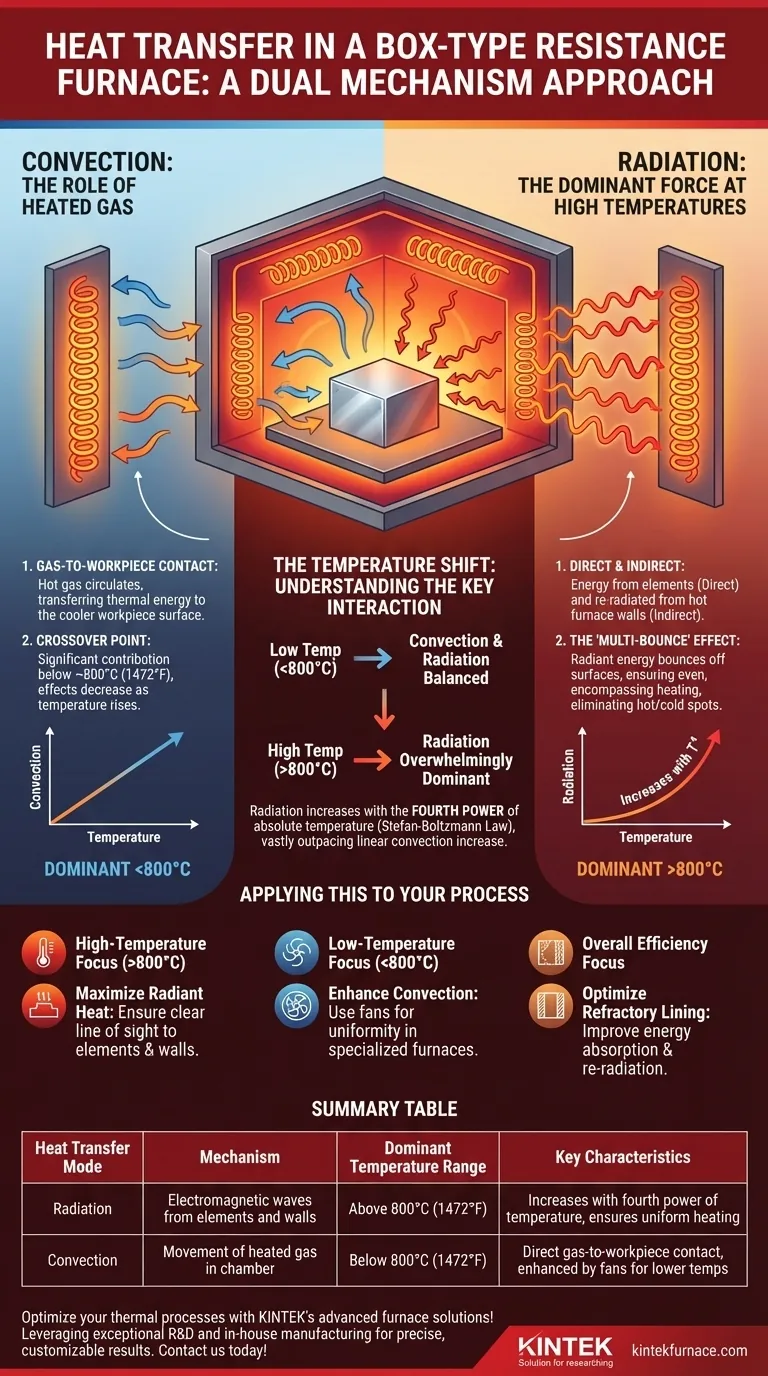

In short, a workpiece in a box-type resistance furnace is heated by a combination of two distinct mechanisms. The primary modes of heat transfer are radiation from the hot heating elements and furnace walls, and convection from the heated gas atmosphere within the furnace chamber.

Understanding the interplay between these two heat transfer modes is critical. While both are always present, their relative importance shifts dramatically with temperature, with radiation becoming the overwhelmingly dominant force at the high temperatures typical of heat treatment processes.

How Convection Transfers Heat

Convection is the process of heat transfer through the movement of a fluid, in this case, the gas (like air) inside the furnace.

Gas-to-Workpiece Contact

As the furnace's heating elements energize, they first heat the gas surrounding them. This hot gas then circulates throughout the chamber and transfers its thermal energy directly to the cooler surface of the workpiece upon contact.

The Temperature Crossover Point

At lower furnace temperatures, approximately below 800°C (1472°F), the effects of convection are significant and can be nearly equal to that of radiation. However, as the temperature rises further, its relative contribution steadily decreases.

The Dominance of Radiation

Radiation is the transfer of energy via electromagnetic waves. It does not require a medium and becomes exponentially more powerful as temperature increases.

Direct and Indirect Radiation

The workpiece is heated by two radiation paths. Direct radiation comes straight from the glowing hot heating elements. Indirect radiation occurs when the furnace's internal walls and roof absorb energy from the elements and then re-radiate that heat onto the workpiece from all directions.

The "Multi-Bounce" Effect

This indirect radiation is vital for uniform heating. Radiant energy from the elements and walls strikes the workpiece and other surfaces. Some is absorbed, and some is reflected, "bouncing" around the chamber until it is eventually absorbed. This creates a more even and encompassing heating effect compared to relying on gas currents alone.

Understanding the Key Interaction

The shift from convection to radiation dominance is not arbitrary; it is governed by fundamental physics and has significant practical implications.

Why Radiation Takes Over

Convective heat transfer increases in a relatively linear fashion with temperature. In contrast, radiant heat transfer increases with the fourth power of the absolute temperature (the Stefan-Boltzmann law). This exponential relationship means that a small increase in temperature results in a massive increase in radiant heat, quickly overshadowing convection's role.

The Impact on Uniformity

Relying on radiation from the large surface area of the furnace walls and roof helps to eliminate hot and cold spots on the workpiece. This is because the part is being "soaked" in thermal energy from all directions, which is often more uniform than potentially turbulent or uneven convective gas currents.

Applying This to Your Process

Your heating strategy depends on understanding which mechanism is doing the most work at your target temperature.

- If your primary focus is rapid, high-temperature heating (>800°C): Focus on maximizing radiant heat transfer. Proper workpiece placement to ensure a clear line of sight to heating elements and hot walls is critical.

- If your primary focus is uniform, lower-temperature processing (<800°C): Recognize the dual role of convection and radiation. In some specialized furnaces, fans are used to enhance convection and ensure temperature uniformity at these lower ranges.

- If your primary focus is overall efficiency: The quality of the furnace's refractory lining is paramount. Its ability to absorb and re-radiate energy inward directly impacts how effectively heat is transferred to the workpiece instead of being lost.

Mastering the balance of radiation and convection is the key to achieving precise and repeatable results in any furnace-based thermal process.

Summary Table:

| Heat Transfer Mode | Mechanism | Dominant Temperature Range | Key Characteristics |

|---|---|---|---|

| Radiation | Electromagnetic waves from elements and walls | Above 800°C (1472°F) | Increases with fourth power of temperature, ensures uniform heating |

| Convection | Movement of heated gas in chamber | Below 800°C (1472°F) | Direct gas-to-workpiece contact, enhanced by fans for lower temps |

Optimize your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to enhance efficiency and achieve superior heat treatment results!

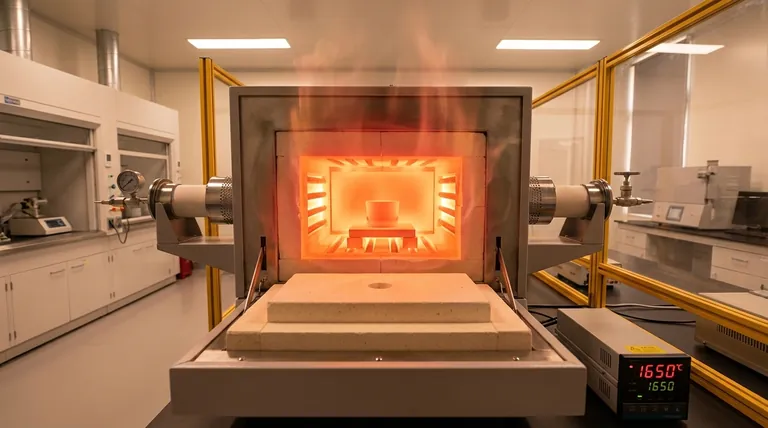

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis