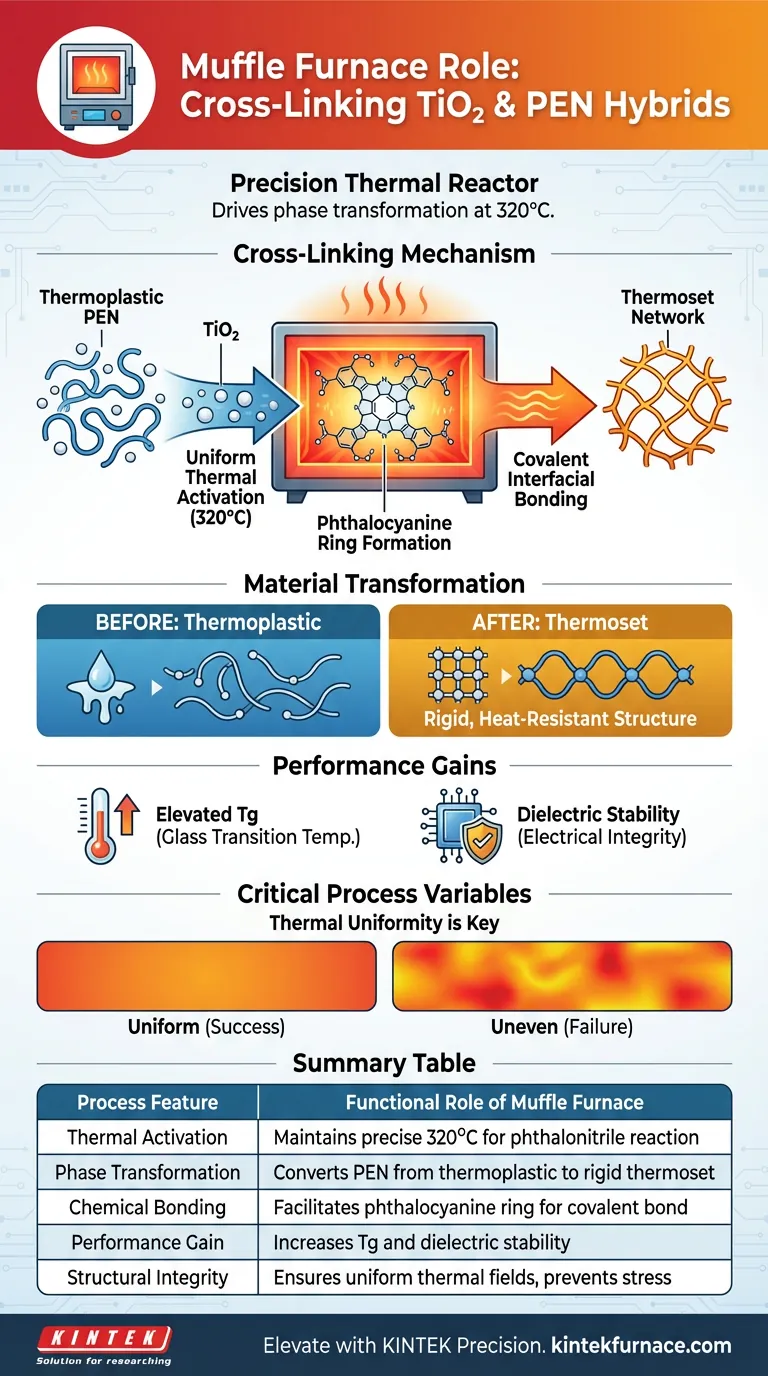

The high-temperature muffle furnace acts as a precision thermal reactor that drives the critical phase transformation of titanium dioxide and poly(ethylene naphthalate) (PEN) composites. Specifically, it provides a uniform thermal field at 320°C to induce the self-cross-linking of phthalonitrile groups, converting the composite from a moldable thermoplastic into a rigid, three-dimensional thermosetting network.

By facilitating the formation of phthalocyanine ring structures, the furnace creates a stable, covalently bonded interface between the inorganic titanium dioxide and the organic polymer matrix. This thermal treatment is the decisive factor in enhancing the material's glass transition temperature and high-temperature dielectric stability.

The Mechanism of Cross-Linking

Uniform Thermal Activation

The primary function of the muffle furnace in this context is to maintain a consistent temperature of 320°C.

This specific thermal energy is required to initiate the chemical reaction of phthalonitrile groups found within the composite. Without this precise and uniform heat, the reaction would be incomplete, leading to weak points in the material matrix.

Formation of Phthalocyanine Rings

Under this sustained heat, the phthalonitrile groups undergo a self-cross-linking reaction.

This reaction results in the formation of phthalocyanine ring structures. These rings act as the chemical anchors that bind the titanium dioxide and the PEN polymer together at a molecular level.

Covalent Interfacial Bonding

The furnace treatment does more than simply mix the materials; it creates true covalent bonds.

This bonding bridges the gap between the organic polymer and the inorganic filler. It eliminates the physical separation often found in composite materials, ensuring the two components act as a unified solid.

Material Transformation and Performance

From Thermoplastic to Thermoset

Before entering the furnace, the PEN-based material is thermoplastic, meaning it can be melted and reshaped.

After the 320°C treatment, the material transforms into a thermosetting cross-linked network. It becomes a permanently set structure that creates a robust three-dimensional framework, resistant to re-melting.

Elevated Glass Transition Temperature

The cross-linking process significantly raises the glass transition temperature (Tg) of the hybrid material.

A higher Tg means the material maintains its mechanical rigidity and structural integrity at much higher operating temperatures than the untreated polymer could withstand.

Dielectric Stability

The furnace-induced network stabilizes the material's electrical properties.

By locking the molecular structure in place, the material exhibits superior high-temperature dielectric stability. This makes it suitable for demanding electronic applications where insulating properties must not degrade under heat.

Critical Process Variables

Importance of Thermal Uniformity

While muffle furnaces are used for various processes (such as calcination or sintering at temperatures up to 1000°C for other materials), the success of this specific PEN/TiO2 process relies on thermal uniformity.

Uneven heating would lead to differential cross-linking rates. This causes internal stresses and inconsistent physical properties across the component.

Precision vs. Speed

The process is not merely about reaching a temperature, but maintaining it to allow the network to form completely.

Rushing the heating rate or shortening the dwell time at 320°C risks leaving unreacted phthalonitrile groups. This results in a material that fails to achieve the desired thermosetting properties or dielectric performance.

Making the Right Choice for Your Goal

To maximize the performance of titanium dioxide and poly(ethylene naphthalate) hybrids, ensure your thermal processing strategy aligns with your end-use requirements:

- If your primary focus is Thermal Stability: Ensure the furnace maintains a strict 320°C dwell time to guarantee the complete conversion from thermoplastic to a thermosetting network.

- If your primary focus is Dielectric Performance: Prioritize the uniformity of the furnace's thermal field to ensure consistent covalent bonding, which prevents electrical breakdown at high temperatures.

Precision in the thermal cross-linking process is the difference between a simple mixture and a high-performance engineering hybrid.

Summary Table:

| Process Feature | Functional Role of Muffle Furnace |

|---|---|

| Thermal Activation | Maintains precise 320°C for phthalonitrile group reaction |

| Phase Transformation | Converts PEN from thermoplastic to a rigid thermoset network |

| Chemical Bonding | Facilitates phthalocyanine ring formation for covalent bonding |

| Performance Gain | Increases glass transition temperature (Tg) and dielectric stability |

| Structural Integrity | Ensures uniform thermal fields to prevent internal material stress |

Elevate Your Material Science with KINTEK Precision

Achieving the perfect cross-linked network for TiO2 and PEN hybrids requires more than just heat—it requires absolute thermal precision. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by expert R&D and manufacturing.

Whether you are developing advanced dielectrics or high-stability composites, our customizable lab high-temperature furnaces ensure the thermal uniformity necessary for critical phase transformations. Contact KINTEK today to discover how our high-performance equipment can optimize your material processing and engineering outcomes.

Visual Guide

References

- High-Temperature Dielectric Energy Storage Materials Fabricated by Crosslinking Titanium Dioxide and Polyarylene Ether Nitrile. DOI: 10.70322/htm.2025.10010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the advantages of using a muffle furnace? Achieve Precise, Contamination-Free Heat Treatment

- Why is a high-temperature muffle furnace required for coal gangue activation? Unlock Maximum Material Reactivity

- What temperature range can muffle furnaces operate at? Find Your Ideal Heat Solution for 800°C to 1800°C

- What paint industry processes utilize muffle furnaces? Essential for Lab Analysis and Quality Control

- What industries commonly use Box Furnaces? Discover Their Versatile Applications Across Key Sectors

- Why is a laboratory muffle furnace core to CCT nanocatalyst prep? Optimize Your Calcination Results

- How does the sealed design of the muffle furnace enhance safety? Protect Operators and Ensure Process Integrity

- What are the limitations of muffle furnaces in industrial applications? Uncover Key Constraints for Smart Lab Choices