While incredibly precise, the primary limitations of muffle furnaces in industrial applications are their inherently small scale, comparatively low thermal efficiency, and the need for specialized operational knowledge. These constraints make them ideal for high-value, small-batch processes but poorly suited for high-volume production.

The limitations of a muffle furnace are not design flaws but direct consequences of its primary function: providing exceptionally pure, uniform, and precise heating. Understanding this trade-off between process purity and production scale is the key to using them effectively.

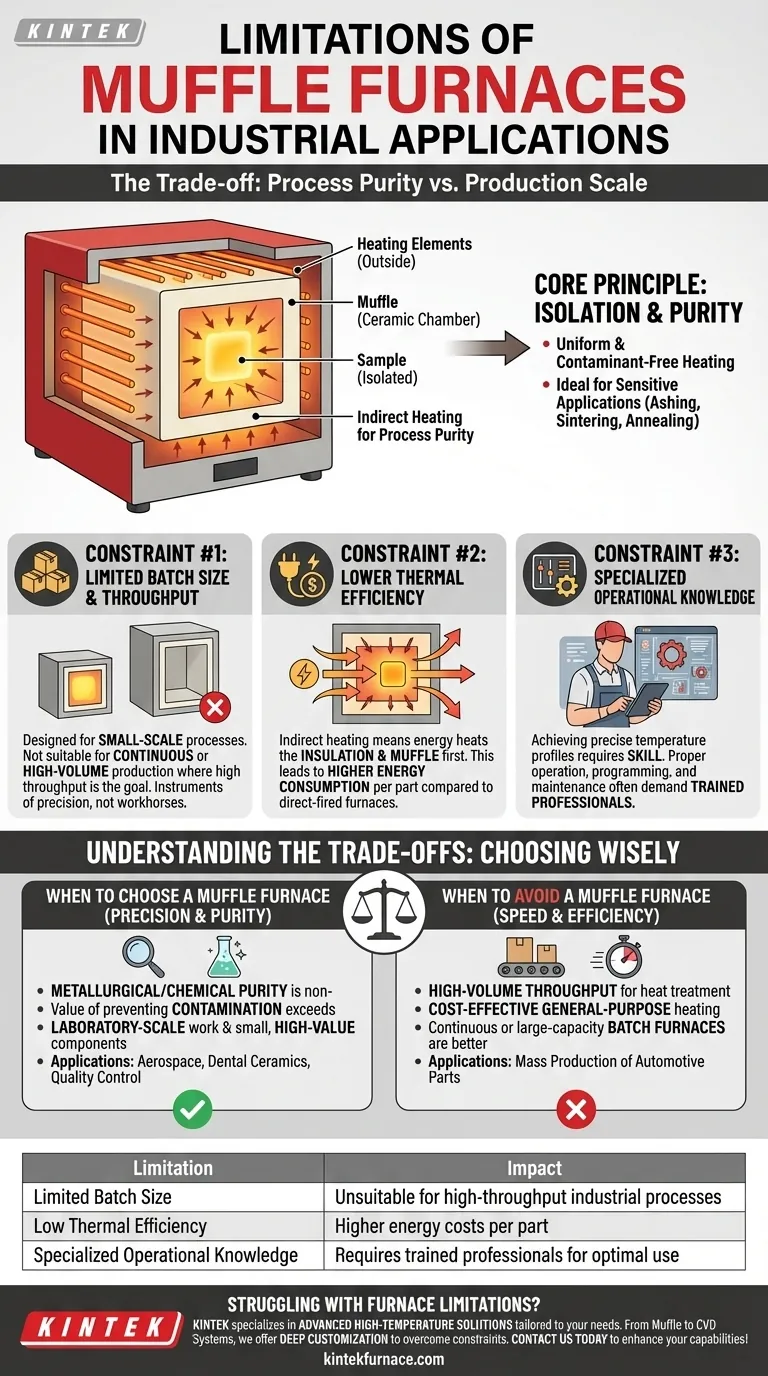

The Core Principle: Process Purity Over Production Volume

To understand the limitations, you must first understand the design. The defining feature of a muffle furnace is the "muffle"—an isolated inner chamber that separates the material being heated from the heating elements and any combustion byproducts.

What is the "Muffle"?

The muffle is essentially a box-like retort made of a refractory ceramic material. It sits inside the furnace's main insulated body.

The heating elements heat the outside of this muffle, and the heat then radiates inward to the sample or component.

The Benefit: Uniform and Contaminant-Free Heating

This design provides two critical advantages: exceptional temperature uniformity and process purity.

Because the material is not exposed to direct radiation from heating elements or any gases from fuel combustion, the heating is extremely even and clean. This is vital for sensitive applications like ashing laboratory samples, sintering advanced ceramics, or annealing delicate semiconductor wafers.

Key Limitations in an Industrial Context

The very design that provides these benefits also creates inherent limitations when scaling up for industrial production.

Constraint #1: Limited Batch Size and Throughput

Muffle furnaces are, by nature, designed for small-scale processes. The need to construct a robust, sealed muffle chamber limits their practical internal volume.

This makes them fundamentally unsuitable for continuous or large-batch production where high throughput is the primary goal. They are instruments of precision, not workhorses of mass production.

Constraint #2: Lower Thermal Efficiency

Energy must first heat the furnace insulation and the thick ceramic muffle itself before it can heat the workload inside. This indirect heating path leads to lower thermal efficiency and potentially higher energy consumption per part compared to a direct-fired furnace.

In industrial settings where energy cost is a major operational expense, this can be a significant drawback for anything other than high-value processes.

Constraint #3: Operational Demands

Achieving and maintaining the precise temperature profiles muffle furnaces are known for requires skill. Proper operation, programming, and maintenance often demand trained professionals.

This is less of a technical limitation and more of an operational one. It introduces a need for specialized labor, which can be a constraint in some industrial environments.

Understanding the Trade-offs

Choosing a muffle furnace is an exercise in weighing priorities. Its limitations only become "disadvantages" when the tool is misapplied to the wrong problem.

Precision Over Speed

A muffle furnace is chosen when the metallurgical or chemical purity of the final product is non-negotiable. The slower, indirect heating process is a necessary trade-off for perfect, uniform results.

Purity Over Energy Cost

The furnace is the right choice when the value added by preventing contamination far exceeds the higher energy cost. This is true in aerospace materials testing, dental ceramic creation, and quality control analysis.

Small Batches vs. Continuous Processing

Muffle furnaces excel at laboratory-scale work and the production of small, high-value components. For processes like hardening thousands of automotive parts, a continuous or large-capacity batch furnace is the correct industrial tool.

Making the Right Choice for Your Goal

To select the right heating technology, clearly define your primary objective.

- If your primary focus is material purity and precise temperature control: The muffle furnace is the ideal instrument for applications like ashing, sintering technical ceramics, or laboratory research.

- If your primary focus is high-volume throughput for heat treatment: A muffle furnace is unsuitable; consider large-scale batch ovens or continuous industrial furnaces instead.

- If your primary focus is cost-effective general-purpose heating: The muffle furnace may be overkill; a simpler, more efficient direct-fired oven might be a better economic choice if minor atmospheric contamination is acceptable.

By aligning the furnace's capabilities with your specific process requirements, you ensure it serves as a precise instrument rather than a production bottleneck.

Summary Table:

| Limitation | Impact |

|---|---|

| Limited Batch Size | Unsuitable for high-throughput industrial processes |

| Low Thermal Efficiency | Higher energy costs per part |

| Specialized Operational Knowledge | Requires trained professionals for optimal use |

Struggling with furnace limitations in your lab? KINTEK specializes in advanced high-temperature solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to overcome constraints like small batch sizes and inefficiency. Whether you're in research, materials testing, or small-batch production, our expertise ensures precise, contaminant-free heating for superior results. Contact us today to discuss how we can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure