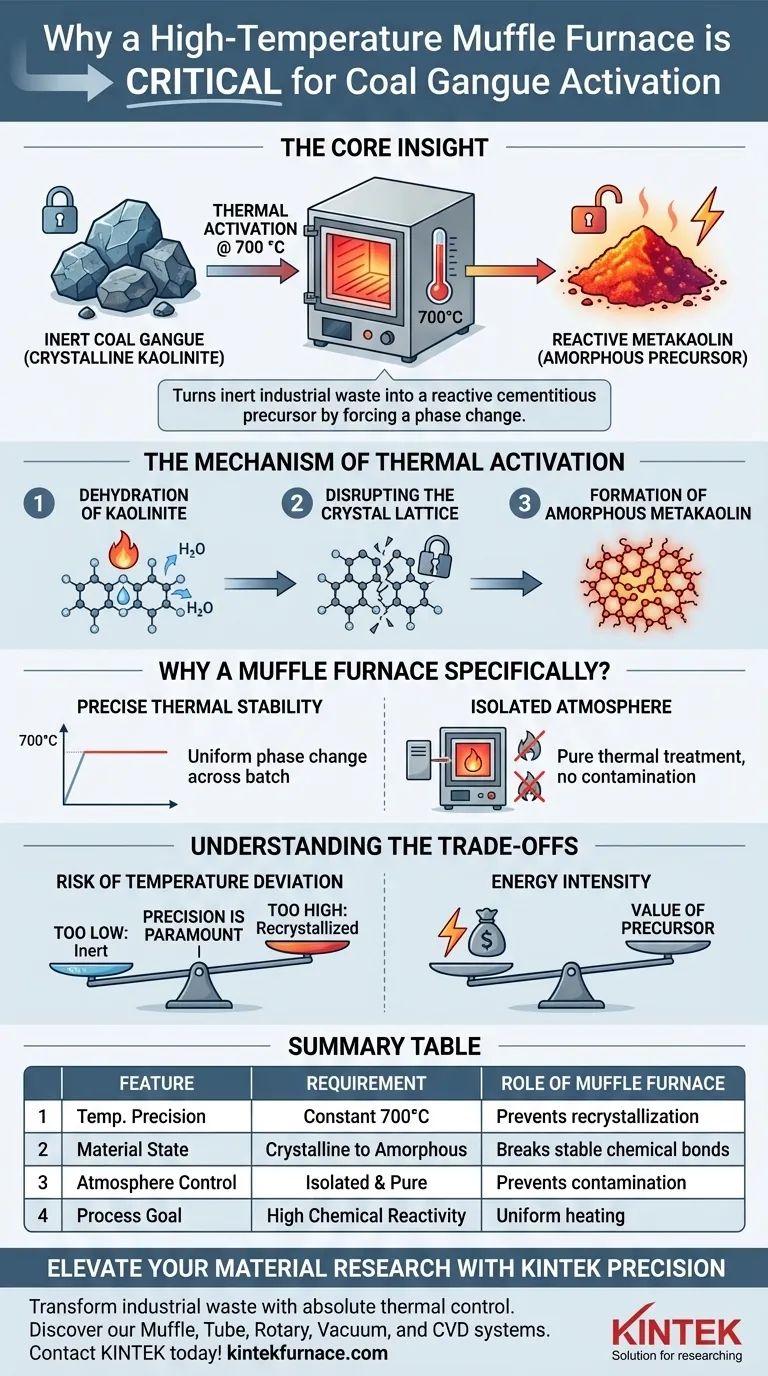

A high-temperature muffle furnace is required to provide a strictly controlled thermal environment, specifically at 700 °C, which is critical for dehydrating the kaolinite found within coal gangue. This process disrupts the material's stable crystal structure, converting it into a highly active, amorphous state known as metakaolin.

Core Insight: The muffle furnace effectively turns inert industrial waste into a reactive cementitious precursor. By maintaining a precise temperature, it forces a phase change from ordered crystalline kaolinite to disordered amorphous metakaolin, which is the key to chemically activating the material.

The Mechanism of Thermal Activation

To understand why this specific equipment is necessary, you must understand the chemical transformation occurring inside the coal gangue.

Dehydration of Kaolinite

Coal gangue contains kaolinite, a clay mineral that is chemically stable and unreactive in its natural state.

The muffle furnace supplies the consistent energy required to remove hydroxyl ions (water) from the kaolinite lattice. This dehydration process is the first step in unlocking the material's potential.

Disrupting the Crystal Lattice

As the water is removed, the highly ordered internal structure of the kaolinite is destabilized.

The heat treatment essentially breaks the "locks" holding the crystal structure together. This disruption is intentional and necessary to change the physical properties of the waste material.

Formation of Amorphous Metakaolin

The ultimate goal of this thermal treatment is the creation of metakaolin.

Unlike the original kaolinite, metakaolin possesses an amorphous (disordered) structure. This lack of structure makes the material chemically "hungry" and highly reactive, allowing it to function as a precursor for cementitious materials.

Why a Muffle Furnace Specifically?

While the temperature (700 °C) is the trigger, the muffle furnace is the necessary tool to ensure that trigger is pulled correctly.

Precise Thermal Stability

The reaction requires a stable 700 °C environment.

Muffle furnaces are engineered to maintain constant temperatures with minimal fluctuation. This stability ensures that the entire batch of material undergoes the same phase change uniformly.

Isolated Atmosphere

Muffle furnaces isolate the sample from direct fuel combustion or external contaminants.

This allows for a pure thermal treatment where the chemical transformation is driven solely by heat, preventing unwanted side reactions that could occur in an open flame environment.

Understanding the Trade-offs

While essential for activation, the use of high-temperature thermal treatment involves critical variables that must be managed.

The Risk of Temperature Deviation

Precision is paramount; simply "heating" the material is insufficient.

If the temperature is too low, the kaolinite will not dehydrate, and the material remains inert. Conversely, extreme overheating can cause the material to recrystallize into stable, non-reactive phases, defeating the purpose of activation.

Energy Intensity

Converting waste into resources via thermal activation is energy-intensive.

The requirement for sustaining 700 °C implies a significant energy cost. This factor must be weighed against the value of the resulting cementitious precursor when designing industrial processes.

Making the Right Choice for Your Goal

When setting up a thermal activation protocol for coal gangue, consider your specific objectives.

- If your primary focus is maximum reactivity: Ensure your furnace is calibrated to exactly 700 °C to achieve the highest proportion of amorphous metakaolin.

- If your primary focus is process consistency: Use a muffle furnace with programmable ramp and soak times to ensure uniform dehydration across all sample batches.

The muffle furnace is not just a heat source; it is the precision instrument that dictates the chemical quality of your final activated material.

Summary Table:

| Feature | Requirement for Coal Gangue Activation | Role of Muffle Furnace |

|---|---|---|

| Temperature Precision | Constant 700 °C | Prevents recrystallization and ensures full dehydration |

| Material State | Crystalline to Amorphous | Breaks stable chemical bonds to create metakaolin |

| Atmosphere Control | Isolated & Pure | Prevents contamination from combustion by-products |

| Process Goal | High Chemical Reactivity | Delivers uniform heating for consistent cementitious precursors |

Elevate Your Material Research with KINTEK Precision

Transforming industrial waste like coal gangue into high-value cementitious precursors requires more than just heat—it requires absolute thermal control. KINTEK provides industry-leading R&D and manufacturing expertise, offering a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-temperature lab applications.

Whether you need precise 700 °C stability for thermal activation or a fully customized furnace for unique material challenges, our expert team is ready to deliver the solution. Don't settle for inconsistent results—contact KINTEK today to optimize your thermal processes!

Visual Guide

References

- Tengfei Wang, Dongming Yang. Mechanism of Activation and Microstructural Evolution in Calcium Carbide Slag-Activated GGBS-CG Composite Cementitious Materials. DOI: 10.3390/ma18174189

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some common applications of box furnaces? Versatile Solutions for Metal Heat Treatment and Material Processing

- What core function does a muffle furnace serve in superconducting material synthesis? Master Solid-State Reactions

- What is the maximum temperature in the muffle furnace? From 1200°C to 1800°C+ Solutions

- What temperature ranges are available for box furnaces? Find the Perfect Fit for Your Thermal Processes

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- Why is a commercial high-temperature furnace required for TL material pretreatment? Ensure Accurate Dosimetry

- Why is a box resistance furnace utilized for the homogenization annealing of alloy micro-wires? Key Benefits Explained

- How does a muffle furnace work and what temperature range does it operate in? Discover Its High-Temp Precision