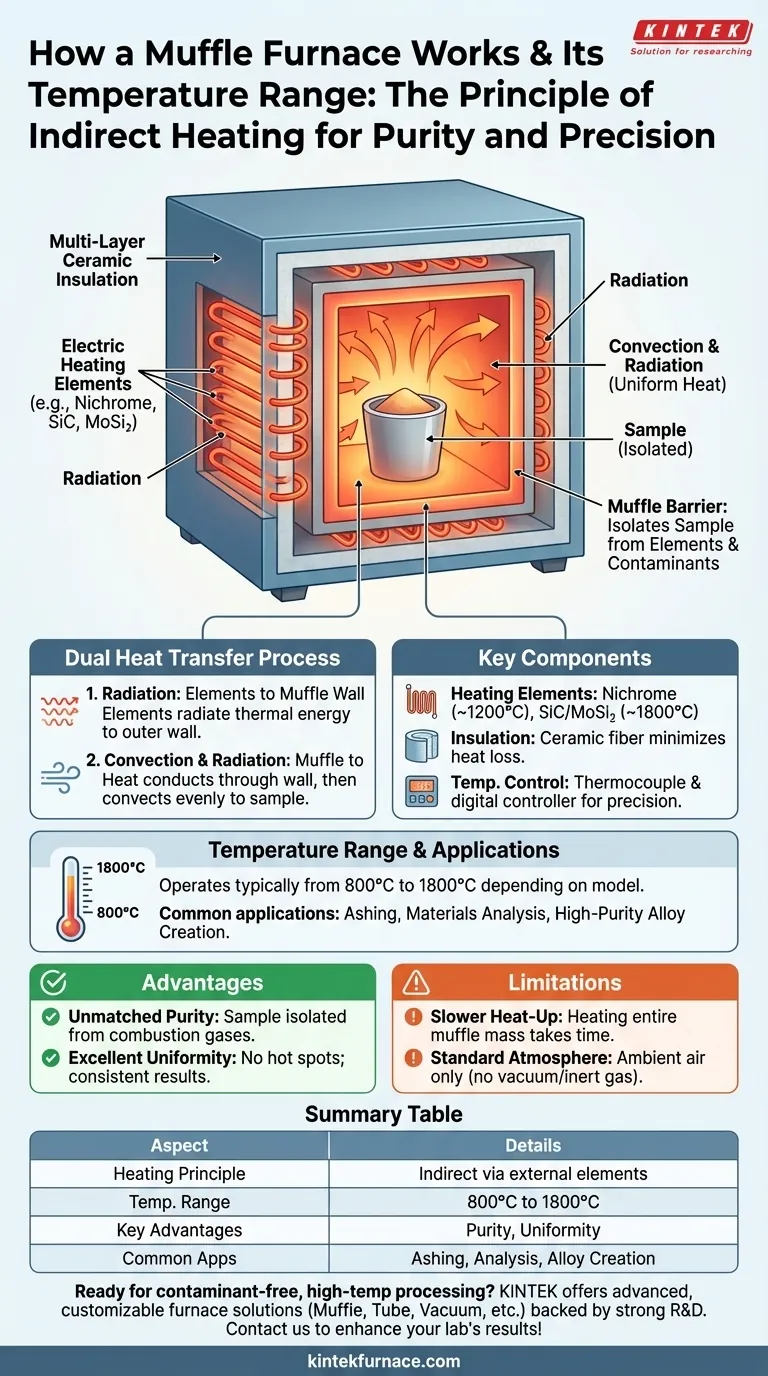

At its core, a muffle furnace works by indirect heating. It uses electric heating elements to heat a separate, insulated chamber—the "muffle"—from the outside, rather than heating the sample directly. This design provides a highly controlled, contaminant-free environment for materials and typically operates in a high-temperature range, generally from 800°C up to 1800°C, depending on the model and application.

The fundamental advantage of a muffle furnace isn't just its ability to reach high temperatures, but its method of doing so. The "muffle" acts as a crucial barrier, separating the material being heated from the heating elements, which is the key to achieving process purity and temperature uniformity.

The Principle of Indirect Heating

The entire design of a muffle furnace is built around isolating the sample to achieve a clean and stable heating environment. This is accomplished through a few key steps.

The Role of the "Muffle"

The "muffle" is the furnace's central chamber, typically made of a high-temperature ceramic material. It houses the sample and is engineered to be chemically inert, even at extreme temperatures.

This chamber is the defining feature, creating a barrier that prevents any byproducts from the heating elements or atmosphere from contaminating the material inside.

Heating Elements and Location

Electric heating elements, often made of materials like nichrome or silicon carbide, are positioned on the outside of the muffle chamber. They are embedded within the furnace's insulating walls.

When electricity passes through these elements, they heat up and glow, but they never come into direct contact with the sample or the atmosphere inside the chamber.

Dual Heat Transfer: Radiation and Convection

Heat gets to the sample in a two-stage process. First, the hot elements radiate thermal energy, which is absorbed by the outer walls of the muffle.

This energy then conducts through the ceramic wall and heats the air and sample inside the chamber primarily through convection and further radiation from the now-hot interior walls. This indirect method ensures a very even and uniform temperature distribution.

Understanding the Key Components

A muffle furnace is a simple system, but each part is critical for its performance.

The Heating Chamber

This is the muffle itself. Its ceramic construction ensures it can withstand thermal shock and does not react with the materials being processed.

Electric Heating Elements

The type of element determines the furnace's maximum temperature. Kanthal (FeCrAl) or nichrome wires are common for temperatures up to around 1200°C.

For higher temperatures (up to 1800°C or more), more robust elements like silicon carbide (SiC) or molybdenum disilicide (MoSi₂) are required.

High-Efficiency Insulation

Multiple layers of ceramic fiber insulation surround the muffle and heating elements. This insulation is critical for minimizing heat loss, allowing the furnace to reach high temperatures efficiently and maintain them stably.

Temperature Control System

A thermocouple probe extends into the chamber to measure the temperature accurately. This is connected to a digital controller that regulates the power sent to the heating elements, allowing for precise temperature management and programmed heating cycles.

Key Advantages and Trade-offs

The design of a muffle furnace offers distinct benefits but also comes with certain limitations you must consider.

Advantage: Unmatched Sample Purity

This is the primary reason to use a muffle furnace. Because the sample is isolated from the heating elements and any potential combustion gases, it is the standard for applications where purity is critical, such as ashing food samples, materials analysis, or creating high-purity alloys.

Advantage: Excellent Temperature Uniformity

The indirect heating mechanism naturally avoids "hot spots." The heat radiates and convects evenly throughout the chamber, ensuring the entire sample experiences the same temperature, which is vital for consistent heat treatment and repeatable results.

Limitation: Slower Heat-Up Times

Heating the entire mass of the ceramic muffle and surrounding insulation takes time. Compared to a direct-fire furnace, a muffle furnace generally has a slower ramp-up rate to its target temperature.

Limitation: Standard Atmosphere Only

A standard muffle furnace operates in ambient air. While it prevents contamination, it does not control the atmospheric composition. For processes that require a vacuum or an inert gas (like nitrogen or argon), a specialized atmosphere furnace is necessary.

Making the Right Choice for Your Goal

Selecting the correct heating method depends entirely on your specific objective.

- If your primary focus is analytical purity and repeatability: The muffle furnace is the ideal choice because its indirect heating design prevents any contamination of your sample.

- If your primary focus is rapid, high-volume heating without purity concerns: A direct-fire kiln or furnace might be more time- and energy-efficient, but you sacrifice the clean environment.

- If your primary focus is processing at temperatures above 1200°C: Ensure you select a muffle furnace specifically equipped with high-temperature elements like silicon carbide (SiC) or MoSi₂.

Understanding this principle of isolated heating empowers you to select the right tool for achieving precise, repeatable, and contaminant-free results in your high-temperature work.

Summary Table:

| Aspect | Details |

|---|---|

| Heating Principle | Indirect heating via external elements, isolating the sample in a muffle chamber |

| Temperature Range | Typically 800°C to 1800°C, depending on model and elements |

| Key Advantages | Unmatched sample purity, excellent temperature uniformity, contaminant-free environment |

| Common Applications | Ashing, materials analysis, high-purity alloy creation |

| Limitations | Slower heat-up times, standard atmosphere only (no vacuum or inert gas control) |

Ready to achieve contaminant-free, high-temperature processing in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis