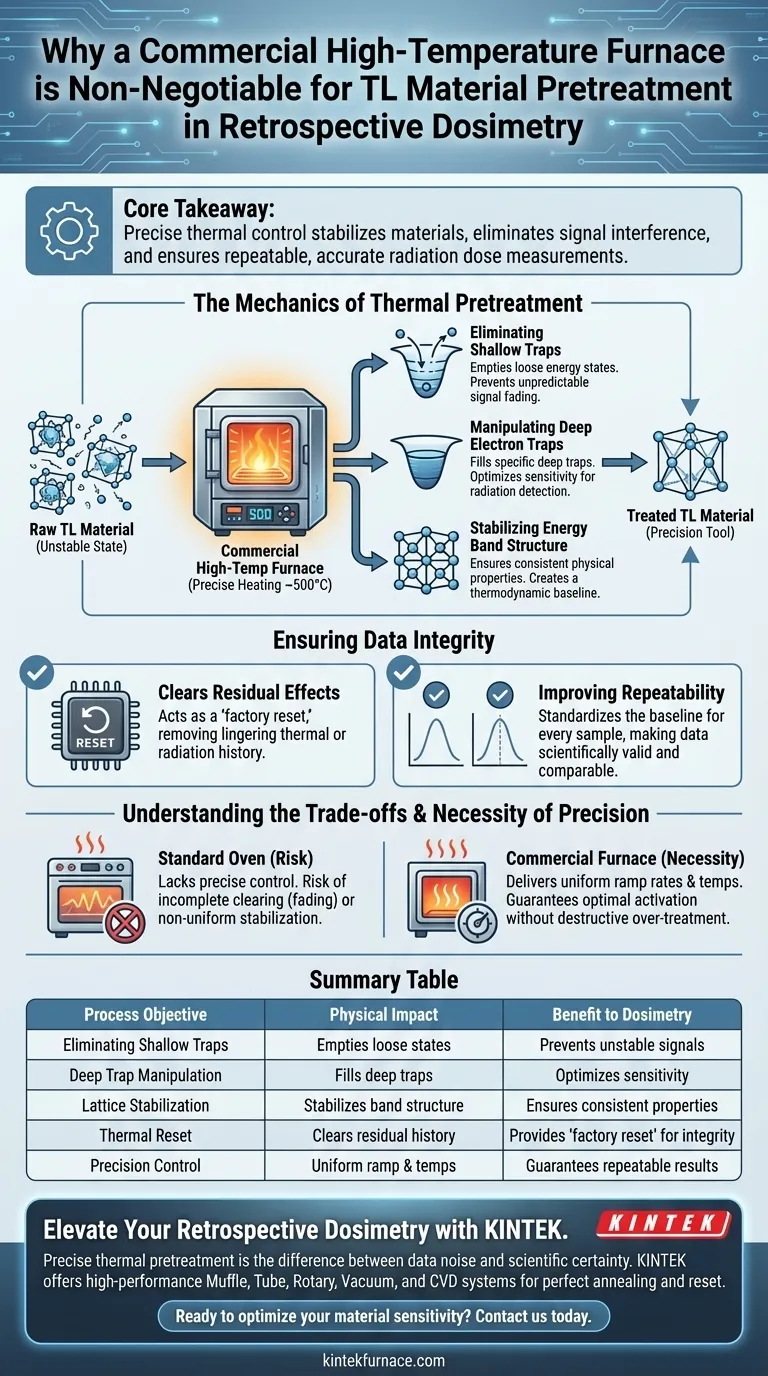

A commercial high-temperature furnace is a non-negotiable requirement for the pretreatment of Thermoluminescence (TL) materials in laboratory retrospective dosimetry. Its primary function is to subject the materials to a precisely controlled annealing or activation process, heating them to several hundred degrees Celsius to reset their physical state before measurement.

Core Takeaway The furnace provides a controlled thermal environment that stabilizes the material's energy band structure and eliminates residual thermal effects. By removing unstable electron traps and resetting the material, this process ensures that subsequent radiation dose measurements are repeatable, accurate, and free from signal interference.

The Mechanics of Thermal Pretreatment

Eliminating Shallow Traps

The primary physical objective of high-temperature treatment is to eliminate shallow traps. These are energy states within the material's lattice that hold electrons loosely.

If left untreated, these shallow traps release electrons unpredictably, causing unstable signals. Heating the material empties these traps, preventing them from interfering with the accurate reading of the dosimetric signal.

Manipulating Deep Electron Traps

Beyond clearing shallow traps, the thermal process is used to fill deep traps with electrons. This is a specific activation treatment that prepares the material for measurement.

By ensuring deep traps are occupied, the sensitivity of the TL material is optimized for the specific type of radiation detection required in retrospective dosimetry.

Stabilizing the Energy Band Structure

The furnace does more than just move electrons; it stabilizes the energy band structure of the crystal lattice.

Thermoluminescence materials can be thermodynamically unstable. A precise heat treatment brings the material to a consistent energy state, ensuring that its physical properties remain constant during the actual readout process.

Ensuring Data Integrity

Clearing Residual Effects

Materials often carry a "history" of previous thermal or radiation exposures. The furnace is used to clear residual thermal stability effects.

This acts as a "factory reset" for the sample. It removes any lingering data or noise from previous uses, ensuring the signal you measure is solely from the radiation dose you intend to study.

Improving Repeatability

The ultimate goal of using a commercial furnace is significantly improving repeatability.

Without a standardized, high-temperature reset, two measurements of the same dose could yield different results. The furnace ensures every sample starts from the exact same baseline, making the data scientifically valid and comparable.

Understanding the Trade-offs

The Necessity of Precision

The reference emphasizes a precisely controlled thermal environment. A standard oven often lacks the necessary temperature uniformity and ramp-rate control required for this delicate physics.

If the temperature is too low, shallow traps remain, leading to signal fading. If the temperature fluctuates, the energy band structure may not stabilize uniformly across the batch.

Risk of Over-treatment

While the reference highlights the need for heating to "several hundred degrees," there is a balance to be struck.

The goal is activation and annealing, not destruction. The commercial furnace allows for specific temperature ceilings to ensure the material is cleared without permanently altering its physical sensitivity to radiation.

Making the Right Choice for Your Goal

To maximize the effectiveness of your retrospective dosimetry, align your furnace usage with your specific experimental needs:

- If your primary focus is signal purity: Prioritize protocols that ensure the complete elimination of shallow traps to prevent unstable "fading" signals.

- If your primary focus is longitudinal study: strict adherence to identical annealing temperatures is critical to maintain the energy band structure across measurements taken at different times.

A precisely controlled thermal pretreatment is the foundation of reliable dosimetry, converting a raw material into a precision measurement tool.

Summary Table:

| Process Objective | Physical Impact | Benefit to Dosimetry |

|---|---|---|

| Eliminating Shallow Traps | Empties loose energy states | Prevents unstable signals and fading |

| Deep Trap Manipulation | Fills deep electron traps | Optimizes sensitivity for radiation detection |

| Lattice Stabilization | Stabilizes energy band structure | Ensures consistent physical properties |

| Thermal Reset | Clears residual thermal history | Provides a "factory reset" for data integrity |

| Precision Control | Uniform ramp rates & temps | Guarantees repeatable, scientifically valid results |

Elevate Your Retrospective Dosimetry with KINTEK

Precise thermal pretreatment is the difference between data noise and scientific certainty. KINTEK provides the high-performance laboratory solutions necessary to ensure your Thermoluminescence materials are perfectly annealed and reset.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard protocols or a custom-engineered furnace for unique research requirements, KINTEK delivers the temperature uniformity and stability your lab demands.

Ready to optimize your material sensitivity? Contact us today to discuss your high-temperature furnace needs with our technical specialists.

Visual Guide

References

- Hayder Khudhair Obayes. Review: Theory of Thermoluminescence & Related by Reuven Chen (Author), Stephen W S Mckeever. DOI: 10.55640/eijmrms-05-07-02

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do muffle furnaces prevent contamination of materials? Ensure Purity in High-Temp Processes

- What is a muffle furnace and how is it related to laboratory furnaces? Discover Precision Heating for Your Lab

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does a high-temperature muffle furnace facilitate the sintering of Sr4Al6O12SO4 ceramics at 1400°C? Expert Guide

- What are the key benefits of using a muffle furnace? Achieve Precise, Contaminant-Free High-Temperature Control

- How does temperature control work in modern muffle furnaces? Achieve Unmatched Precision and Efficiency

- Why is compact design beneficial in a muffle furnace? Maximize Thermal Efficiency and Save Space

- What is the role of a Muffle Furnace in the thermal modification of wood? Optimize Daniellia oliveri Durability