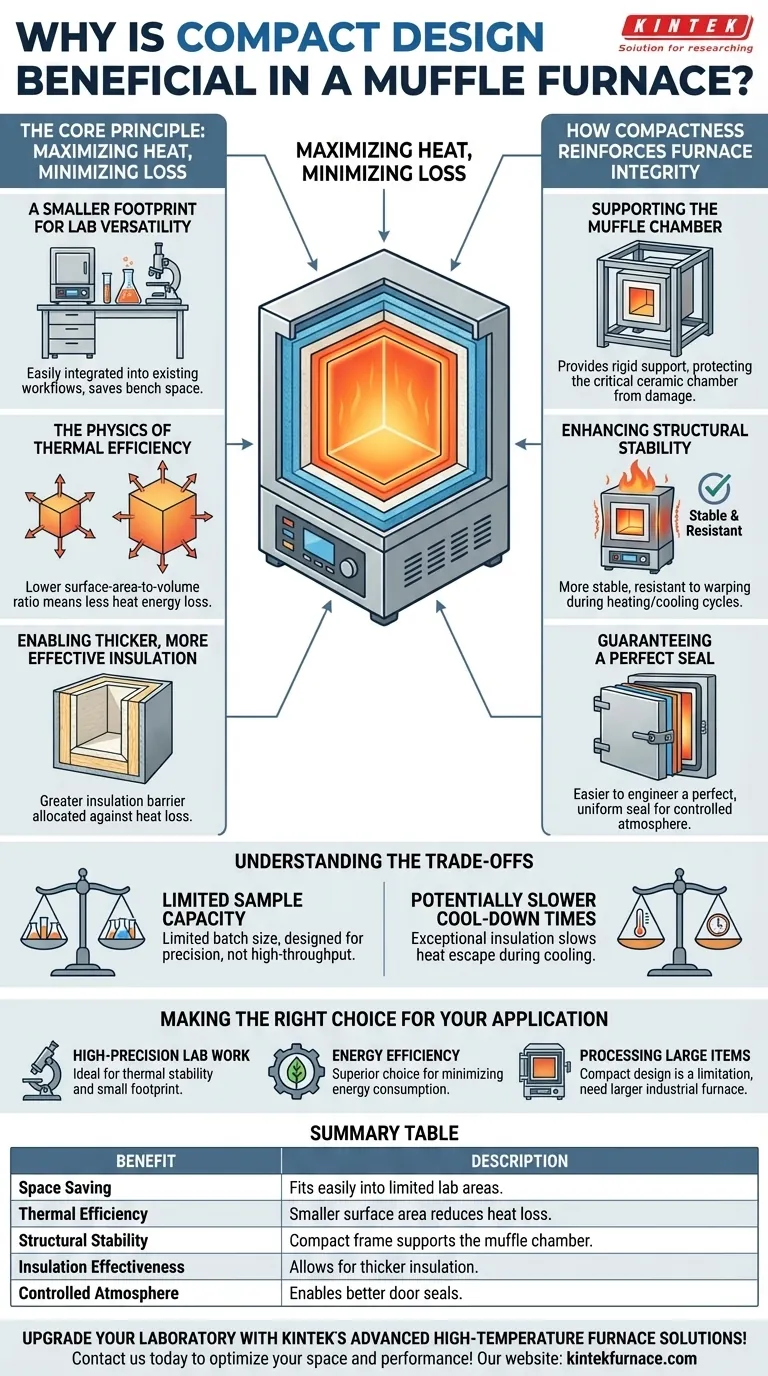

At its core, a compact design is beneficial in a muffle furnace for two primary reasons: it allows the unit to fit within limited laboratory spaces, and more importantly, it is fundamental to the furnace's ability to achieve and maintain extreme temperatures efficiently. The smaller external surface area minimizes heat loss, a critical factor in high-temperature applications.

The compact nature of a muffle furnace is not merely a space-saving feature; it is an integral part of its thermal design. This form factor directly enables superior heat retention, temperature uniformity, and energy efficiency, which are the primary goals of its operation.

The Core Principle: Maximizing Heat, Minimizing Loss

The design of a muffle furnace is a masterclass in thermal management. Every feature is engineered to generate and contain intense heat within a precise, controlled chamber. A compact design is the physical foundation of this principle.

A Smaller Footprint for Lab Versatility

The most immediate benefit is practical. Laboratories and research facilities are often constrained by bench space. The compact design allows these powerful tools to be integrated easily into existing workflows without requiring a dedicated, oversized area.

The Physics of Thermal Efficiency

Heat naturally dissipates from a surface. A smaller furnace has a lower surface-area-to-volume ratio. This simple geometric fact means there is less external surface through which valuable heat energy can escape, making the furnace inherently more efficient at maintaining its target temperature.

Enabling Thicker, More Effective Insulation

Because the overall volume is contained, designers can allocate a greater proportion of the furnace's construction to high-performance insulation. This thick barrier, often made of advanced ceramic fibers, is the primary defense against heat loss and is made more effective by the compact structure it surrounds.

How Compactness Reinforces Furnace Integrity

Beyond simple heat retention, the compact design reinforces the furnace's ability to create a perfectly isolated and stable operating environment.

Supporting the Muffle Chamber

A muffle furnace works by heating a sample indirectly. Heating elements are outside the central "muffle" chamber, which ensures the sample is not exposed to contaminants from combustion or the elements themselves. A robust, compact frame provides the rigid support needed to protect this critical ceramic chamber.

Enhancing Structural Stability

Extreme temperatures place immense stress on materials. A compact, tightly-engineered structure is inherently more stable and resistant to the warping or structural failure that can occur during repeated heating and cooling cycles. This ensures a long and reliable service life.

Guaranteeing a Perfect Seal

To maintain a controlled atmosphere and prevent heat leakage, the door seal is critical. Advanced muffle furnaces use multi-layer seals and complex locking mechanisms. A smaller door and frame make it easier to engineer a perfect, uniform seal, which is vital for both safety and performance.

Understanding the Trade-offs

While highly beneficial, the compact design is not without its compromises. Objectivity requires acknowledging these limitations.

Limited Sample Capacity

The most obvious trade-off is batch size. A compact furnace is, by definition, limited in the volume or number of samples it can process at one time. It is designed for precision and control, not high-throughput production.

Potentially Slower Cool-Down Times

The same exceptional insulation that holds heat in so effectively also slows its escape during cooling. If your process requires rapid thermal cycling, the high thermal mass and insulation of a compact furnace can become a bottleneck.

Making the Right Choice for Your Application

Selecting a furnace requires aligning its design characteristics with your specific operational goals.

- If your primary focus is high-precision lab work: A compact design is ideal, as it provides the thermal stability and small footprint required for research environments.

- If your primary focus is energy efficiency: A compact furnace with thick insulation is the superior choice for minimizing energy consumption while holding high temperatures.

- If your primary focus is processing large or numerous items: A compact design is a direct limitation, and a larger industrial furnace is the necessary tool for the job.

Ultimately, the celebrated compact design of a muffle furnace is a deliberate engineering choice that prioritizes thermal efficiency and control over sheer volume.

Summary Table:

| Benefit | Description |

|---|---|

| Space Saving | Fits easily into limited laboratory areas, enhancing workflow integration. |

| Thermal Efficiency | Smaller surface area reduces heat loss, improving temperature control and energy use. |

| Structural Stability | Compact frame supports the muffle chamber, ensuring durability and reliable performance. |

| Insulation Effectiveness | Allows for thicker insulation, boosting heat retention and operational safety. |

| Controlled Atmosphere | Enables better door seals for maintaining precise conditions and preventing contamination. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior thermal efficiency and reliability. Contact us today to discuss how our compact muffle furnaces can optimize your space and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation