A high-temperature muffle furnace serves as the critical reaction chamber for sintering Sr4Al6O12SO4 ceramics. It provides a stable 1400°C environment, which acts as the mandatory energy threshold to trigger solid-state chemical reactions between the Al2O3, SrCO3, and SrSO4 precursors. Sustaining this temperature for four hours ensures the material undergoes a complete structural transformation, resulting in a dense, single-phase ceramic.

The muffle furnace provides more than just heat; it creates a stable equilibrium that eliminates porosity and organizes the crystal lattice. This controlled thermal soak is the defining factor in establishing the material's mechanical strength and corrosion resistance.

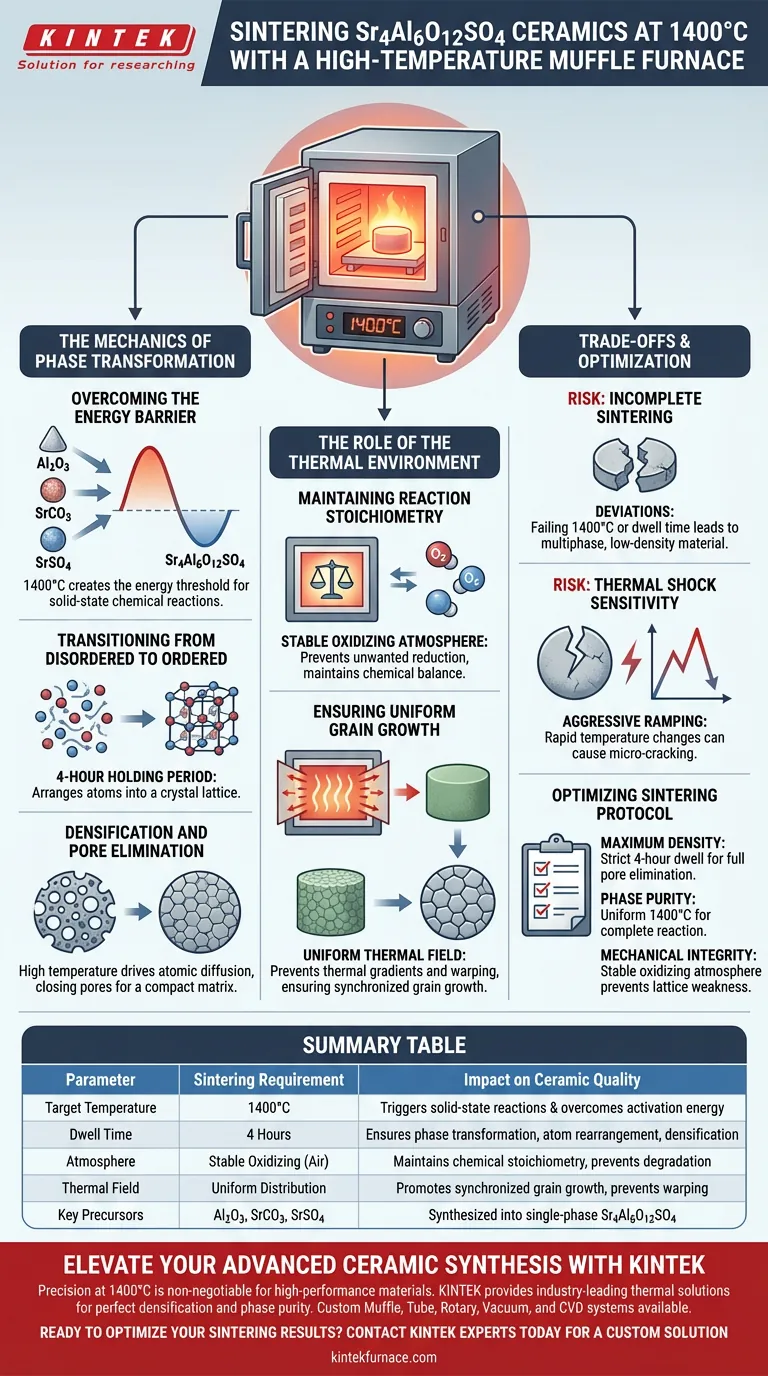

The Mechanics of Phase Transformation

Overcoming the Energy Barrier

The synthesis of Sr4Al6O12SO4 is not a simple mixture but a complex chemical evolution. The muffle furnace must maintain a stable 1400°C temperature to overcome the activation energy barrier required for the raw materials—Al2O3, SrCO3, and SrSO4—to interact. Without reaching this precise thermal threshold, the necessary solid-state reactions cannot initiate.

Transitioning from Disordered to Ordered States

Once the reaction begins, the material exists in a transitionary, disordered state. The furnace facilitates a four-hour holding period at peak temperature, which drives the rearrangement of atoms into a highly ordered crystal structure. This sustained energy input is essential for the full development of the Sr4Al6O12SO4 phase.

Densification and Pore Elimination

As the crystal structure organizes, the ceramic matrix densifies. The high-temperature environment promotes the diffusion of atoms, effectively closing and eliminating residual pores within the material. This results in a compact matrix that is crucial for high-performance applications.

The Role of the Thermal Environment

Maintaining Reaction Stoichiometry

In a high-temperature muffle furnace, the air atmosphere typically provides a stable oxidizing environment. For oxide-based ceramics, this is vital to maintain the correct chemical balance (stoichiometry) and prevent unwanted reduction reactions that could degrade the material's purity.

Ensuring Uniform Grain Growth

A key advantage of a quality muffle furnace is the generation of a uniform thermal field. This uniformity ensures that the ceramic green body heats evenly, preventing thermal gradients that cause warping. It allows for synchronized grain growth, leading to a dense structure with equiaxed (roughly equal-sized) grains.

Understanding the Trade-offs

The Risk of Incomplete Sintering

While 1400°C is the target, deviations in temperature consistency can lead to significant defects. If the furnace fails to maintain this threshold across the entire chamber, or if the four-hour dwell time is shortened, the solid-state reaction will remain incomplete. This results in a multiphase material with lower density and compromised mechanical properties.

Thermal Shock Sensitivity

Ceramics are generally sensitive to rapid temperature changes. While the primary goal is reaching 1400°C, the heating and cooling rates must be controlled. Aggressive ramping can induce thermal stress, leading to micro-cracking in the densified matrix before the process is finished.

Optimizing the Sintering Protocol

To achieve the best results with Sr4Al6O12SO4 ceramics, align your furnace parameters with your specific material goals.

- If your primary focus is Maximum Density: Ensure the dwell time is strictly maintained at four hours to allow full pore elimination and atomic diffusion.

- If your primary focus is Phase Purity: Verify that the furnace maintains a uniform 1400°C throughout the chamber to guarantee the complete reaction of all precursors (Al2O3, SrCO3, and SrSO4).

- If your primary focus is Mechanical Integrity: utilize a stable oxidizing atmosphere to prevent stoichiometric imbalances that weaken the crystal lattice.

Precise control of the 1400°C thermal soak is the single most important variable in engineering a corrosion-resistant, high-strength ceramic.

Summary Table:

| Parameter | Sintering Requirement | Impact on Ceramic Quality |

|---|---|---|

| Target Temperature | 1400°C | Triggers solid-state chemical reactions and overcomes activation energy |

| Dwell Time | 4 Hours | Ensures complete phase transformation, atom rearrangement, and densification |

| Atmosphere | Stable Oxidizing (Air) | Maintains chemical stoichiometry and prevents material degradation |

| Thermal Field | Uniform Distribution | Promotes synchronized grain growth and prevents warping/cracking |

| Key Precursors | Al2O3, SrCO3, SrSO4 | Successfully synthesized into a single-phase Sr4Al6O12SO4 structure |

Elevate Your Advanced Ceramic Synthesis with KINTEK

Precision at 1400°C is non-negotiable for high-performance materials like Sr4Al6O12SO4. KINTEK provides the industry-leading thermal solutions required to achieve perfect densification and phase purity.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique sintering protocols, ensuring uniform grain growth and mechanical integrity for your most demanding applications.

Ready to optimize your sintering results?

Contact KINTEK experts today for a custom solution

Visual Guide

References

- José A. Rodríguez‐García, Enrique Rocha‐Rangel. Chemical Interaction between the Sr4Al6O12SO4 Ceramic Substrate and Al–Si Alloys. DOI: 10.3390/eng5010025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis

- What is the primary function of a high-temperature muffle furnace in LFP regeneration? Restore Battery Life with Precision

- In which industries are muffle furnaces commonly used? Essential for Clean High-Temp Processing

- How does the exhaust system in some muffle furnaces contribute to safety? Prevent Hazards and Ensure Safe Operation

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- What is the recommended operating temperature to extend the lifespan of the furnace wire? Maximize Longevity with a 50°C Buffer

- What role does a muffle furnace play in Al2O3/PTFE composites? Optimize Sintering for Superior Performance

- What are some major applications of muffle furnaces in research and industry? Unlock Precision Heat for Your Lab