Muffle furnaces are fundamental tools used across a diverse range of scientific and industrial fields. Their core applications are found in materials science, analytical chemistry, metallurgy, and quality control, enabling high-temperature processes that require a clean, controlled environment free from combustion contaminants.

The defining feature of a muffle furnace isn't just its ability to generate high heat, but its use of an isolated chamber (the "muffle"). This ensures the material being heated is never exposed to the flame or heating elements, making it essential for processes where purity and precise thermal transformation are critical.

The Core Function: Controlled Heating in an Isolated Chamber

A muffle furnace's value comes from its unique design, which separates the workload from the heat source. Understanding this principle is key to seeing why it's so widely adopted.

What is a "Muffle"?

The "muffle" is a sealed, high-temperature-resistant chamber, typically made of ceramic, that contains the material being processed. Heating elements are positioned on the outside of this chamber.

This design provides indirect heating. Heat radiates through the chamber walls to the material inside, ensuring a uniform and controlled thermal environment.

Why Isolation Matters

By separating the material from the heating source (often gas combustion or electric elements), the furnace prevents contamination. There are no combustion byproducts, like soot or gases, that can react with and alter the sample. This is critical for analytical testing and creating high-purity materials.

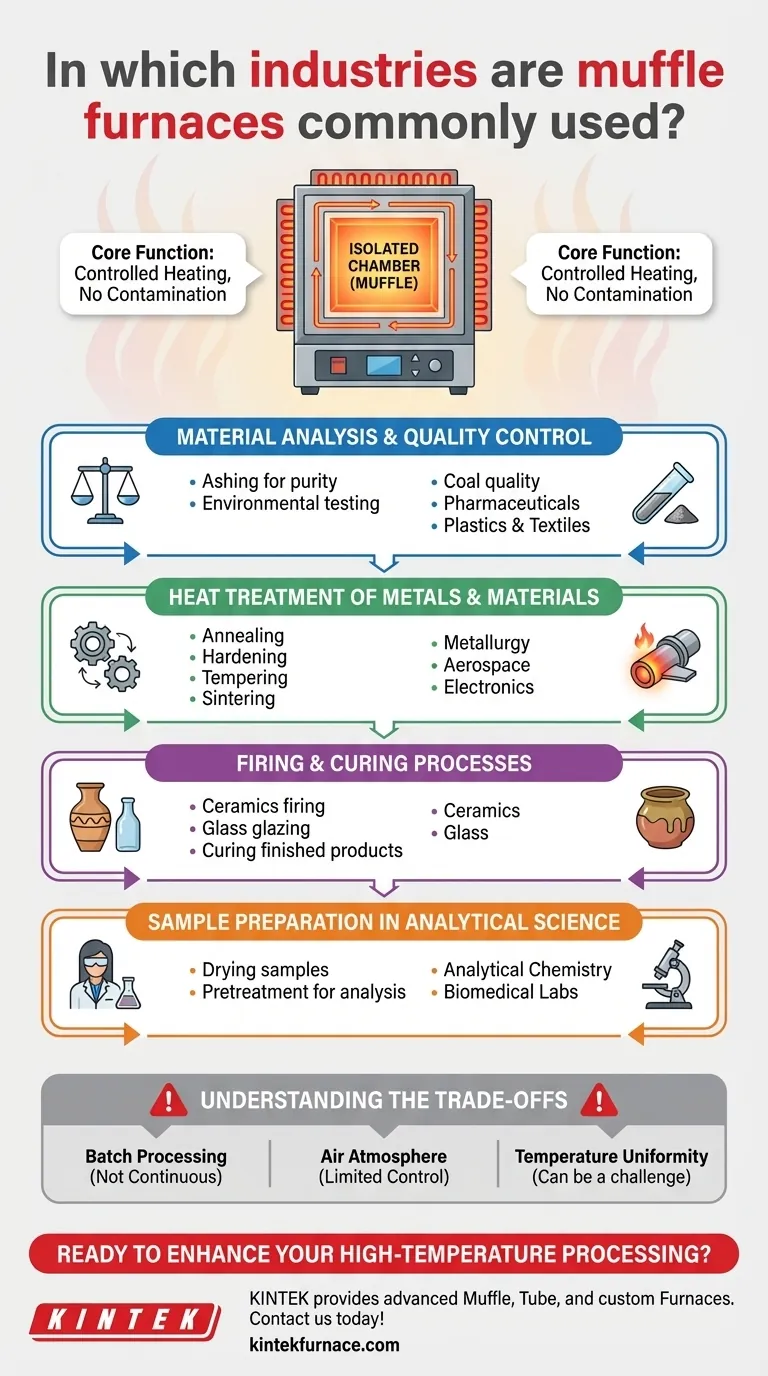

Key Applications Across Industries

The need for clean, high-temperature processing drives the adoption of muffle furnaces in several key sectors. The application, more than the industry itself, defines the need.

Material Analysis and Quality Control

This is one of the most common uses. The furnace is used to burn away all organic and combustible material, leaving only the non-combustible content, or "ash."

This process, known as ashing, is essential in industries like coal quality analysis, environmental testing, pharmaceuticals, plastics, and textiles to determine the composition and purity of a sample.

Heat Treatment of Metals and Materials

The metallurgy, aerospace, and electronics industries rely on muffle furnaces for precise heat treatment of components.

Common processes include:

- Annealing: Heating and slowly cooling a metal to reduce hardness and improve ductility.

- Hardening: Heating and rapidly cooling steel to increase its strength.

- Tempering: Reheating a hardened part to a lower temperature to reduce brittleness.

- Sintering: Fusing powdered materials together using heat, below their melting point.

Firing and Curing Processes

The ceramics and glass industries use muffle furnaces for firing, glazing, and curing finished products.

The controlled heating and cooling cycles are vital for hardening ceramic bodies and setting glazes without causing cracks from thermal shock. It's also used in creating specialized glass and enamel coatings.

Sample Preparation in Analytical Science

In analytical chemistry and biomedical labs, muffle furnaces prepare samples for further analysis.

This can involve drying samples at a specific temperature, burning off organic matrixes before elemental analysis, or performing other high-temperature pretreatment steps required for various testing protocols.

Understanding the Trade-offs

While versatile, muffle furnaces are not the universal solution for all heating applications. It's important to recognize their limitations.

Batch Processing vs. Continuous Flow

Muffle furnaces are inherently batch-processing tools. You load a sample, run a cycle, and then unload it. They are not suited for large-scale, continuous production lines, which often require tunnel kilns or conveyor belt furnaces.

Atmosphere Control

A standard muffle furnace operates in an air atmosphere. While it isolates the sample from combustion fumes, it does not create a vacuum or inert gas environment. Processes that require a specific atmosphere (like argon or nitrogen) to prevent oxidation need more specialized furnace designs.

Temperature Uniformity

Achieving perfect temperature uniformity throughout the entire chamber can be a challenge, especially in larger or more basic models. For applications requiring extremely tight thermal precision, high-end models with multiple heating zones and advanced controllers are necessary.

Making the Right Choice for Your Goal

The ideal muffle furnace depends entirely on the process you need to perform.

- If your primary focus is analytical testing (ashing): You need a furnace with excellent temperature accuracy and a reliable ventilation system to safely remove byproducts.

- If your primary focus is metal heat treatment: You need a furnace that can reach high temperatures, maintain them with stability, and ideally has programmable cycles for complex treatments.

- If your primary focus is ceramics or glass work: You need a furnace with highly programmable heating and cooling rates to manage thermal stress and prevent product failure.

Ultimately, the muffle furnace is the go-to instrument for any task that demands precise, high-temperature processing in a contaminant-free environment.

Summary Table:

| Industry | Key Applications |

|---|---|

| Materials Science & Quality Control | Ashing, sample purity analysis |

| Metallurgy, Aerospace, Electronics | Annealing, hardening, tempering, sintering |

| Ceramics & Glass | Firing, glazing, curing processes |

| Analytical Chemistry & Biomedical | Sample preparation, drying, pretreatment |

Ready to enhance your lab's high-temperature processing with a tailored muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs in industries such as materials science, metallurgy, and quality control. Contact us today to discuss how our high-temperature furnace solutions can drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating